Feed and preparation method thereof

A feed and weight meter technology, which is applied in the field of green plant materials to prepare feed, can solve the problems of no nutritional supplement or improvement, poor fattening effect, and increased cost, and achieve the effect of low price, significant effect, and sufficient sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

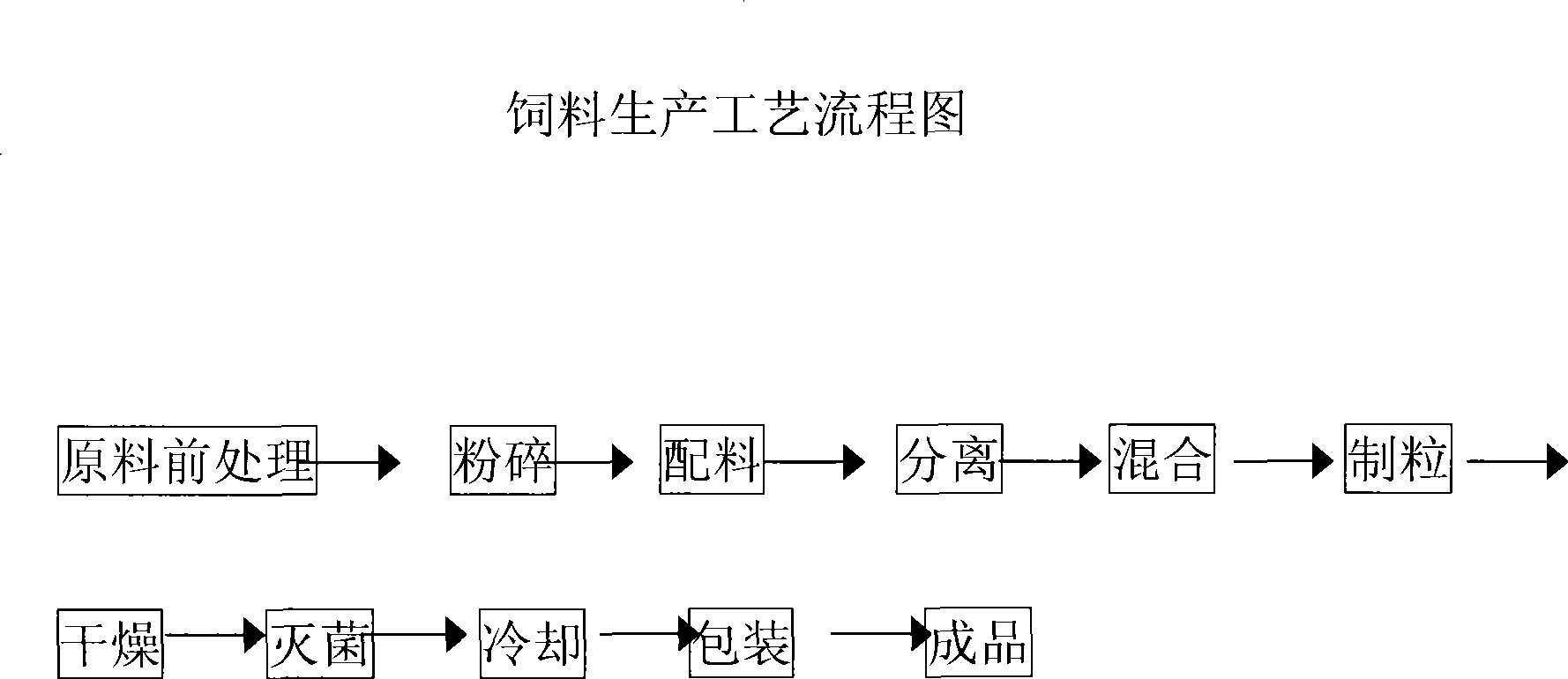

[0018] (1) Crush caragana, Nitraria pomace, seabuckthorn pomace, and corn to 10 mesh, 20 mesh, 20 mesh, and 10 mesh respectively, and press 30 kg of Caragana powder, 30 kg of Nitraria pomace powder, and seabuckthorn pomace Flour 15 kg, corn flour 25 kg ratio for batching;

[0019] (2) Put the above-mentioned ingredients into a three-position motion mixer to mix, stir evenly, and put into a magnetic separator for demagnetization;

[0020] (3) the mixture demagnetized in step (2) is inserted into a tank mixer and mixed;

[0021] (4) Drying, sterilizing, cooling and packaging the mixture in step (3) to obtain the finished feed.

Embodiment 2

[0023] (1) Grind caragana, Nitraria pomace, and seabuckthorn pomace to 15 mesh, 25 mesh, and 25 mesh respectively, according to the ratio of 70 kg of Caragana powder, 15 kg of Nitraria pomace powder, and 15 kg of seabuckthorn pomace powder Ingredients;

[0024] (2) Put the above-mentioned ingredients into a three-position motion mixer to mix, stir evenly, and put into a magnetic separator for demagnetization;

[0025] (3) the mixture demagnetized in step (2) is inserted into a tank mixer and mixed;

[0026] (4) Drying, sterilizing, cooling and packaging the mixture in step (3) to obtain the finished feed.

Embodiment 3

[0028] (1) Grind caragana, Nitraria pomace, seabuckthorn pomace, and corn to 20 mesh, 30 mesh, 30 mesh, and 20 mesh respectively, and press 40 kg of Caragana powder, 20 kg of Nitraria pomace powder, and sea buckthorn pomace 30 kg of flour and 10 kg of corn flour are used for batching;

[0029] (2) Put the above-mentioned ingredients into a three-position motion mixer to mix, stir evenly, and put into a magnetic separator for demagnetization;

[0030] (3) the mixture demagnetized in step (2) is inserted into a tank mixer and mixed;

[0031] (4) Drying, sterilizing, cooling and packaging the mixture in step (3) to obtain the finished feed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com