A method for preparing clo2 using combined BSC reducing reagent

A chlorine dioxide and production method technology, applied in the direction of chlorine oxidation, etc., can solve problems such as increased foam generation, pipeline blockage, and relatively expensive hydrogen peroxide, and achieve the effects of reduced ingredients and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

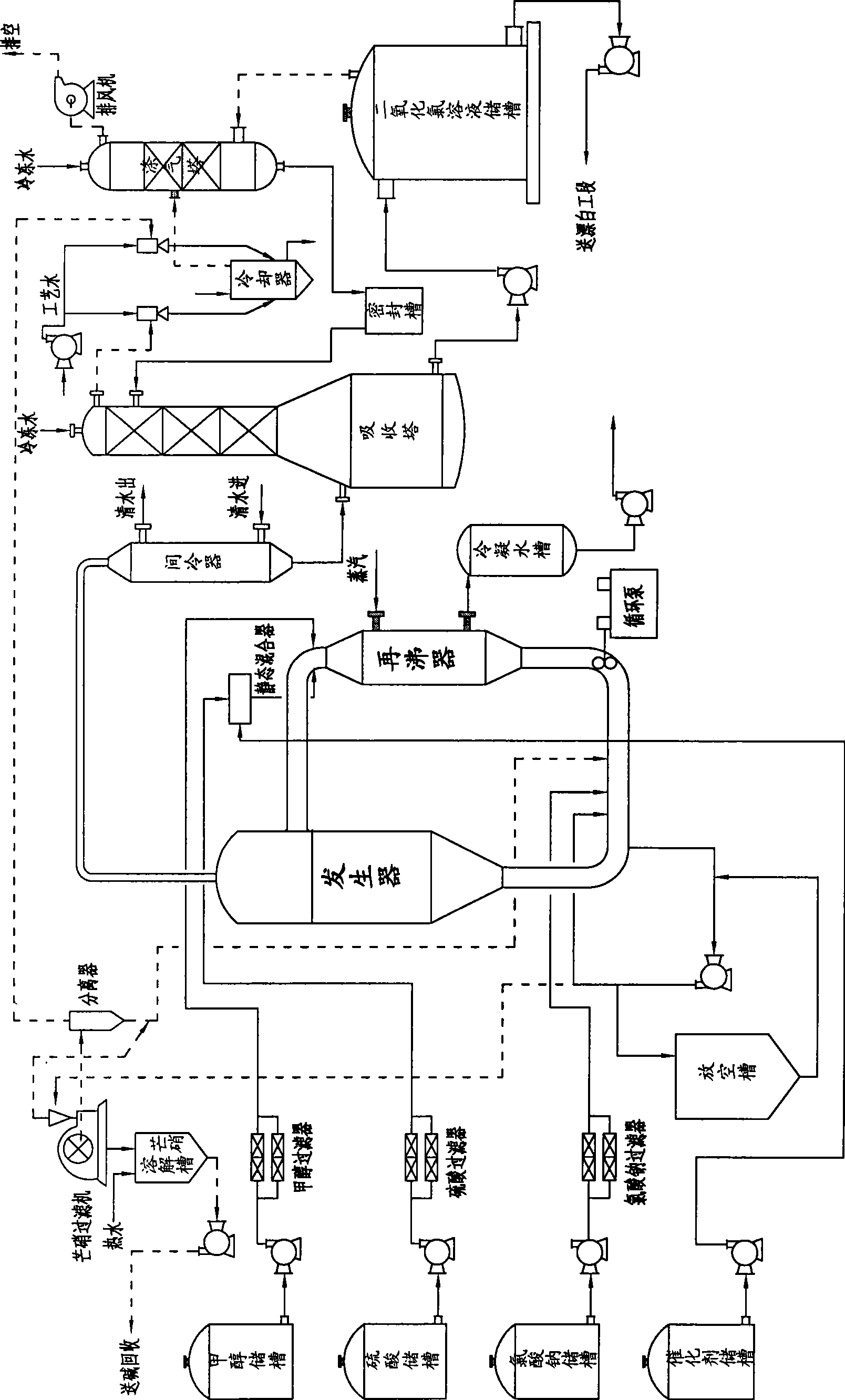

Image

Examples

Embodiment 1

[0017] 102 kg of concentrated sulfuric acid with a weight concentration of 98% and 543 kg of sodium chlorate solution (containing 163 kg of solid sodium chloride) with a weight concentration of 30% are filtered and injected into the generator to form a reaction mother liquor, which is circulated in the generator under the action of a circulation pump Circulate in the pipeline and keep the acidity of the reaction mother liquor at 8.0-8.2N and the content of sodium chlorate at 235-266g / l. The steam transfers heat through the reboiler to heat the reaction mother liquor and keep the temperature at 71-73°C. Dilute 13kg of methanol to a volume concentration of 20%, mix it with 0.7kg of hydrogen peroxide through a static mixer to form a combined BSC reducing agent, inject it into the generator through a nozzle, and make it react to generate chlorine dioxide. The generator maintains a vacuum condition at a pressure of 120 mm Hg, and the vacuum is generated by two Venturi devices pumpe...

Embodiment 2

[0019] 1020kg of concentrated sulfuric acid with a weight concentration of 98% and 543kg of sodium chlorate solution (containing 163kg of solid sodium chloride) with a weight concentration of 30% are filtered and injected into the generator to form a reaction mother liquor, which is circulated in the generator under the action of a circulating pump Circulate in the pipeline and keep the acidity of the reaction mother liquor at 8.0-8.2N and the content of sodium chlorate at 235-266g / l. The steam transfers heat through the reboiler to heat the reaction mother liquor and keep the temperature at 71-73°C. Dilute methanol with a weight of 14kg to a volume concentration of 20%, and mix it with hydrogen peroxide with a weight of 0.9kg to form a combined BSC reducing agent through a static mixer, and inject it into the generator through a nozzle to make the reaction generate chlorine dioxide. The generator maintains a vacuum condition at a pressure of 120 mm Hg, and the vacuum is gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com