Method for preparing copper porous material

A technology of porous material and copper metal, applied in the field of preparation of copper metal porous material, can solve the problems of long production process, uneven distribution of pore structure, low material strength, etc., and achieve the effect of stable and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A copper-chromium alloy with a Cr element mass fraction of 40% is selected, wherein the Cr element in the copper-chromium alloy exists in the form of particles. use 1000 # Polish the surface of the copper-chromium alloy sample with metallographic sandpaper, the sample size is 10mm×10mm×3mm, rinse with water, degrease with absolute ethanol and dry at 20°C. Then immerse the surface-treated copper-chromium alloy sample in 1 liter of H2O containing 20 g of NaCl at a concentration of 2.7 mol / L. 2 SO 4 In the solution, the temperature of the solution is 25°C, and the oscillation frequency is 70KHz. After soaking for 20 hours, the test sample is taken out, rinsed with clean water, and dried to obtain a copper metal porous material.

Embodiment 2

[0016] A copper-chromium alloy with a Cr element mass fraction of 50% is selected, wherein the Cr element in the copper-chromium alloy exists in the form of particles. use 1000 # Polish the surface of the copper-chromium alloy sample with metallographic sandpaper, the sample size is 10mm×10mm×3mm, rinse with water, degrease with absolute ethanol and dry at 40°C. Then immerse the surface-treated copper-chromium alloy sample in 1 liter of H with a concentration of 3.0 mol / liter and 15 grams of NaCl 2 SO 4 In the solution, the temperature of the solution is 30°C, and the oscillation frequency is 40KHz. After soaking for 15 hours, the test sample is taken out, rinsed with clean water, and dried to obtain a copper metal porous material.

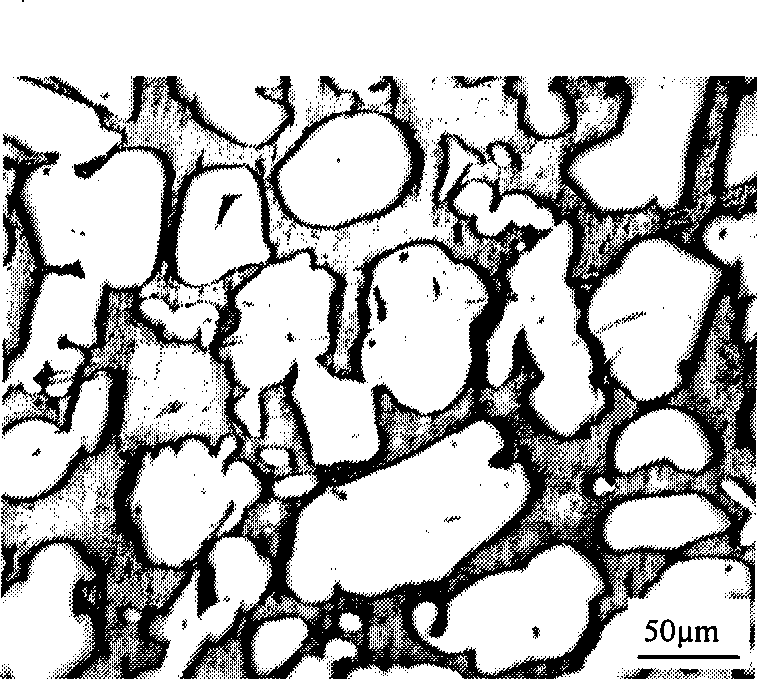

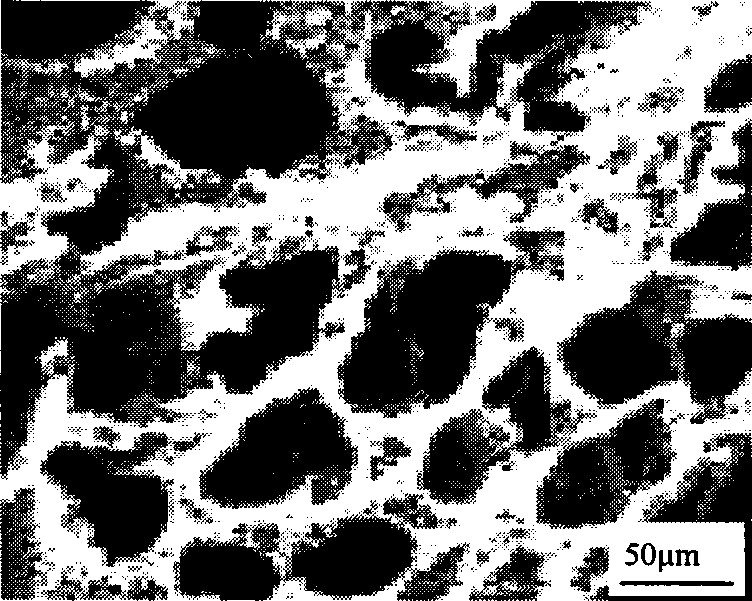

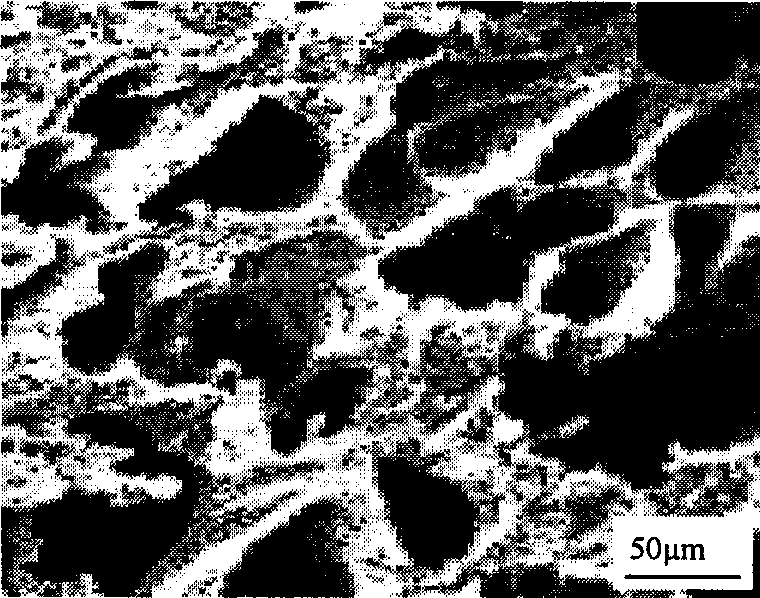

[0017] It was found by Neophot21 metallographic microscope that the structure of copper-chromium alloy is composed of Cu phase and Cr phase, wherein Cr phase is distributed in Cu matrix in irregular granular form (see figure 1 ), Example 1 and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap