Vibration isolation device and application thereof

A vibration isolation and coupling device technology, which is applied in protection devices, non-rotational vibration suppression, roads, etc., can solve the problems of very difficult on-site maintenance restrictions, large size of coupling sleeve, cost reduction and transportation, etc., and achieve vibration isolation effect Good, the effect of improving strength and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

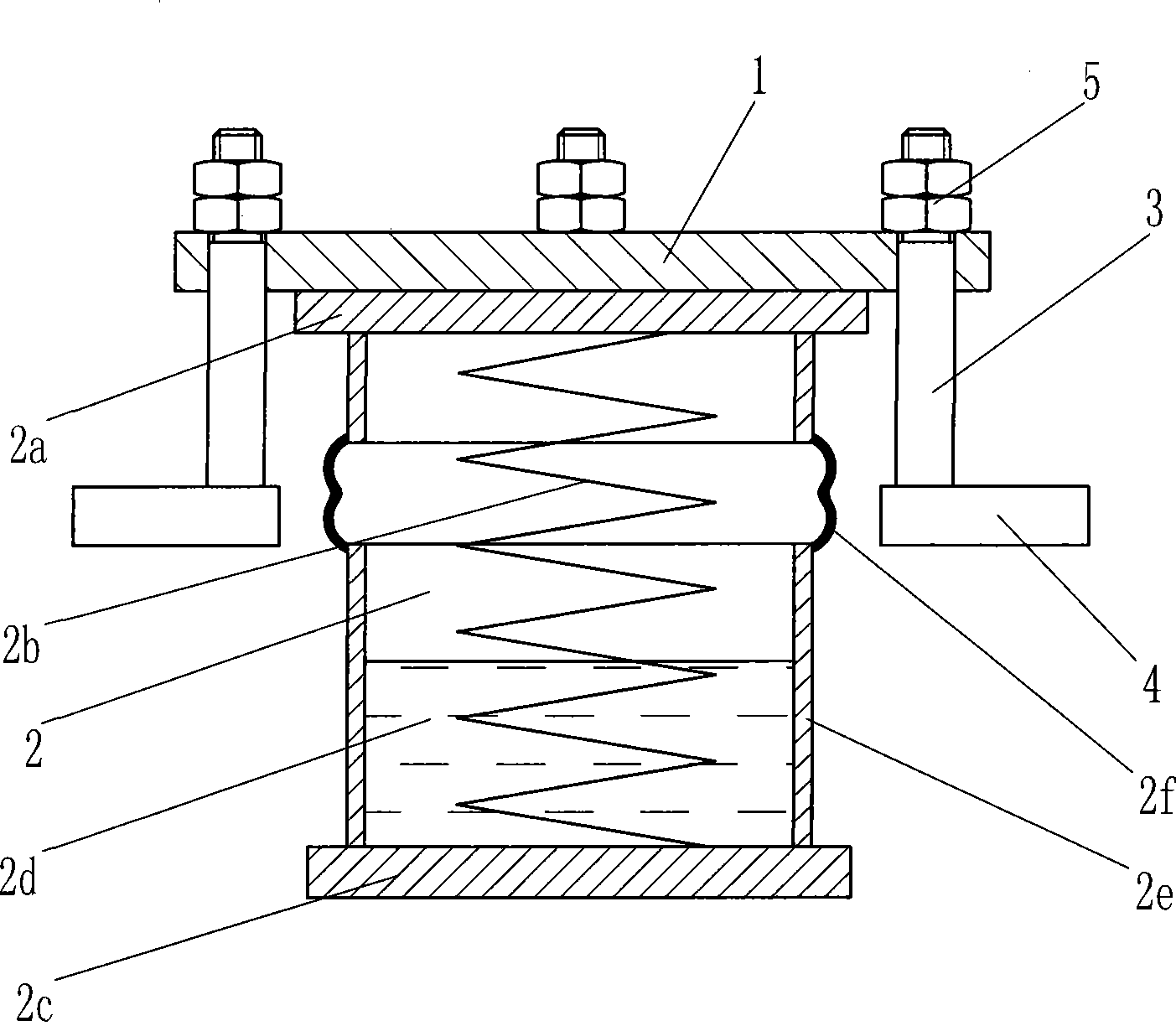

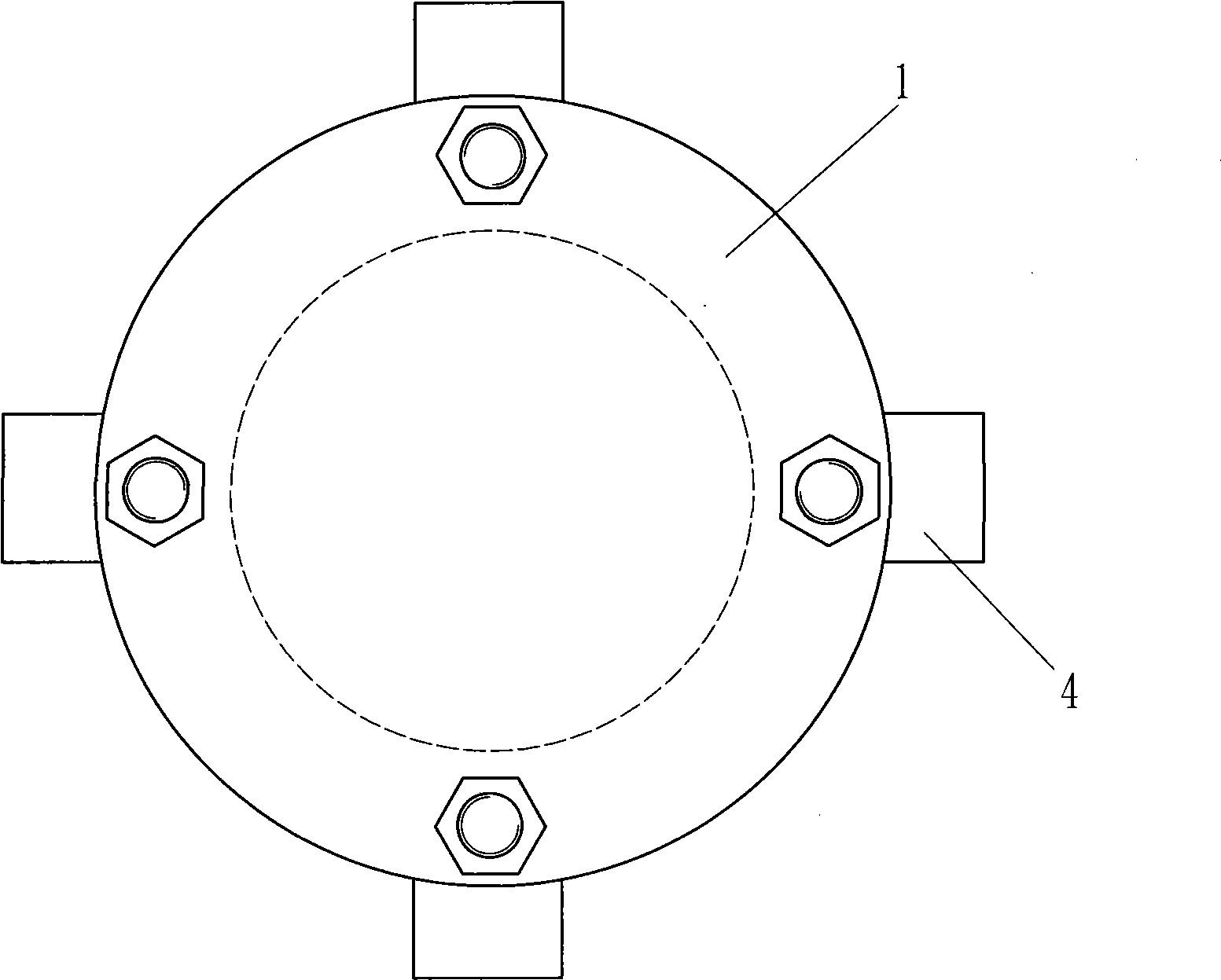

[0030] Such as figure 1 , figure 2 The vibration isolation device of the present invention shown includes a supporting block 1 and a spring vibration isolator 2. The spring vibration isolator 2 is located below the supporting block 1. The spring vibration isolator 2 consists of an upper top plate 2a, a spring 2b, and a lower top plate 2c. , Liquid damper 2d, damper cylinder 2e and dust cover 2f. The support block 1 is provided with four rotatable booms 3, and the lower part of the boom 3 is horizontally provided with a hook block 4 extending outward. The rotatable boom 3 is arranged through the supporting block 1, and the upper part is provided with a thread structure and is fitted with a lock nut 5.

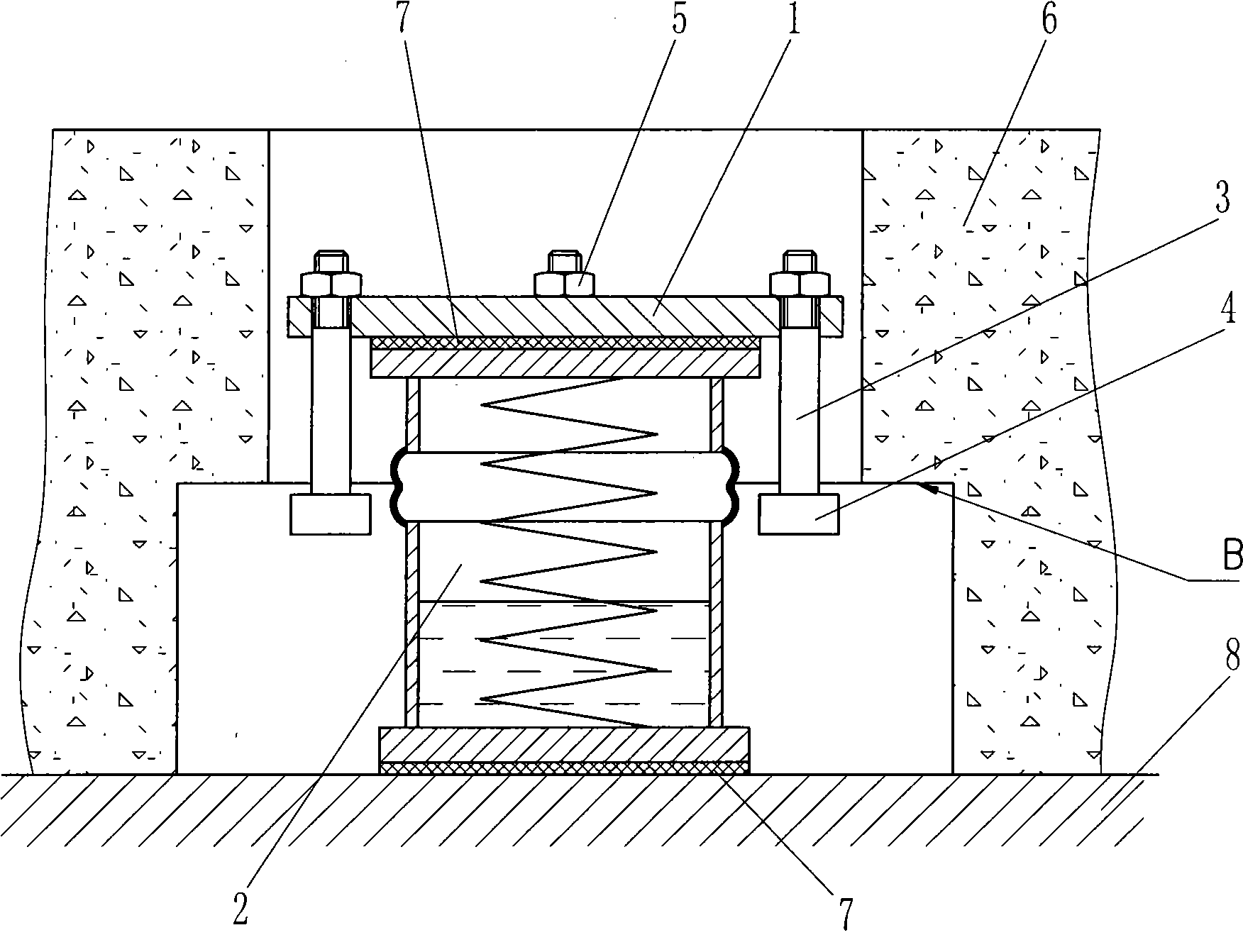

[0031] Such as image 3 As shown, the vibration isolation member 6 is a floating plate of a floating track bed. In application, the supporting block 1 and the spring vibration isolator 2 are sequentially placed in the reserved through holes of the floating plate 6, and the reserve...

Embodiment 2

[0037] In order to facilitate the lifting of the component to be vibration-isolated directly from above and the spring vibration isolator can be directly installed from above, such as Figure 5 , Figure 6 The difference between the vibration isolation device of the present invention shown in the first embodiment is that a gasket 10 is added. The gasket 10 is placed between the spring isolator 2 and the supporting block 1, which can pass through the center hole of the supporting block and be connected to the supporting block. A staggered overlap is formed between the stoppers, and a center hole is provided on the support stopper 1 corresponding to the size of the washer 10 and the spring vibration isolator 2. In order to facilitate the lifting operation, a lifting block 11 is provided between the lock nuts 5.

[0038] When used in the track floating plate, such as Figure 7 As shown, a reserved through hole corresponding to the shape of the vibration isolation device is preset on ...

Embodiment 3

[0044] Such as Picture 9 As shown, the difference from the second embodiment is that a shoulder 31 is provided on the boom 3, and the shoulder 31 is used to cooperate with the supporting block 1 to limit the position, and the boom 3 is connected to the hook block by a threaded structure provided at its lower end. And use the lock nut to lock the hook block. When the boom is assembled with the supporting block, the boom can be passed through the supporting block from top to bottom and then connected with the hook block. In addition, the setting of the jacking block 11 can also be integrated with the lock nut 5. In this way, if the size of the threaded section of the upper part of the boom 3 is standardized, the jacking block integrated with the lock nut can be removed and used for the next vibration isolator after completing the jacking of one vibration isolator. The jacking up is conducive to saving materials and further reducing costs. The gasket 10 is provided in multiple piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com