Double fuel gas cycle hot blast stove of waste gas direct combustion and indirect heat transfer

A hot blast stove and circulating fan technology, applied in air heaters, heating devices, fluid heaters, etc., can solve the problems of low heat energy utilization, large kerosene consumption, high power consumption, etc., to achieve safe operation and improve thermal efficiency , high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

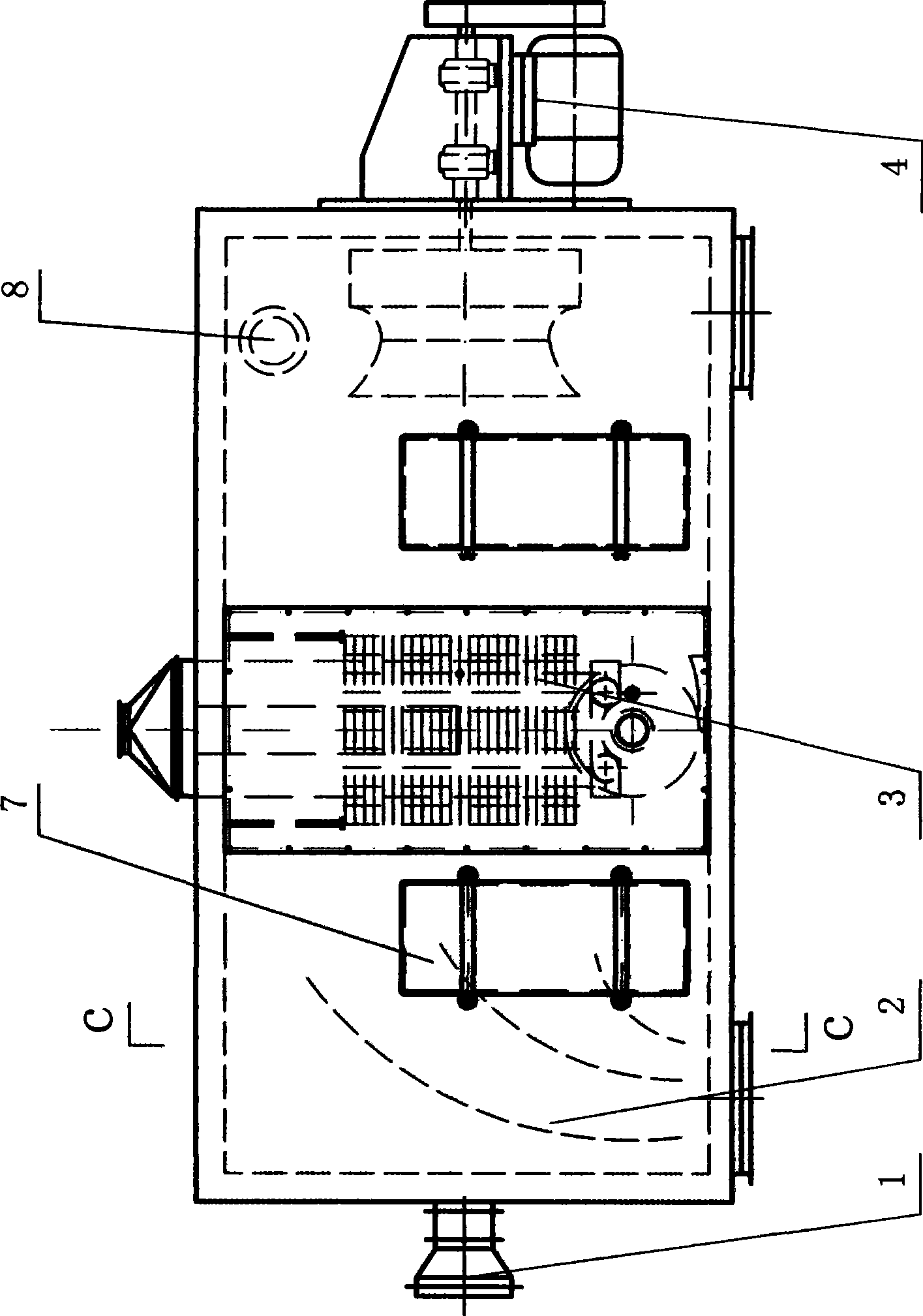

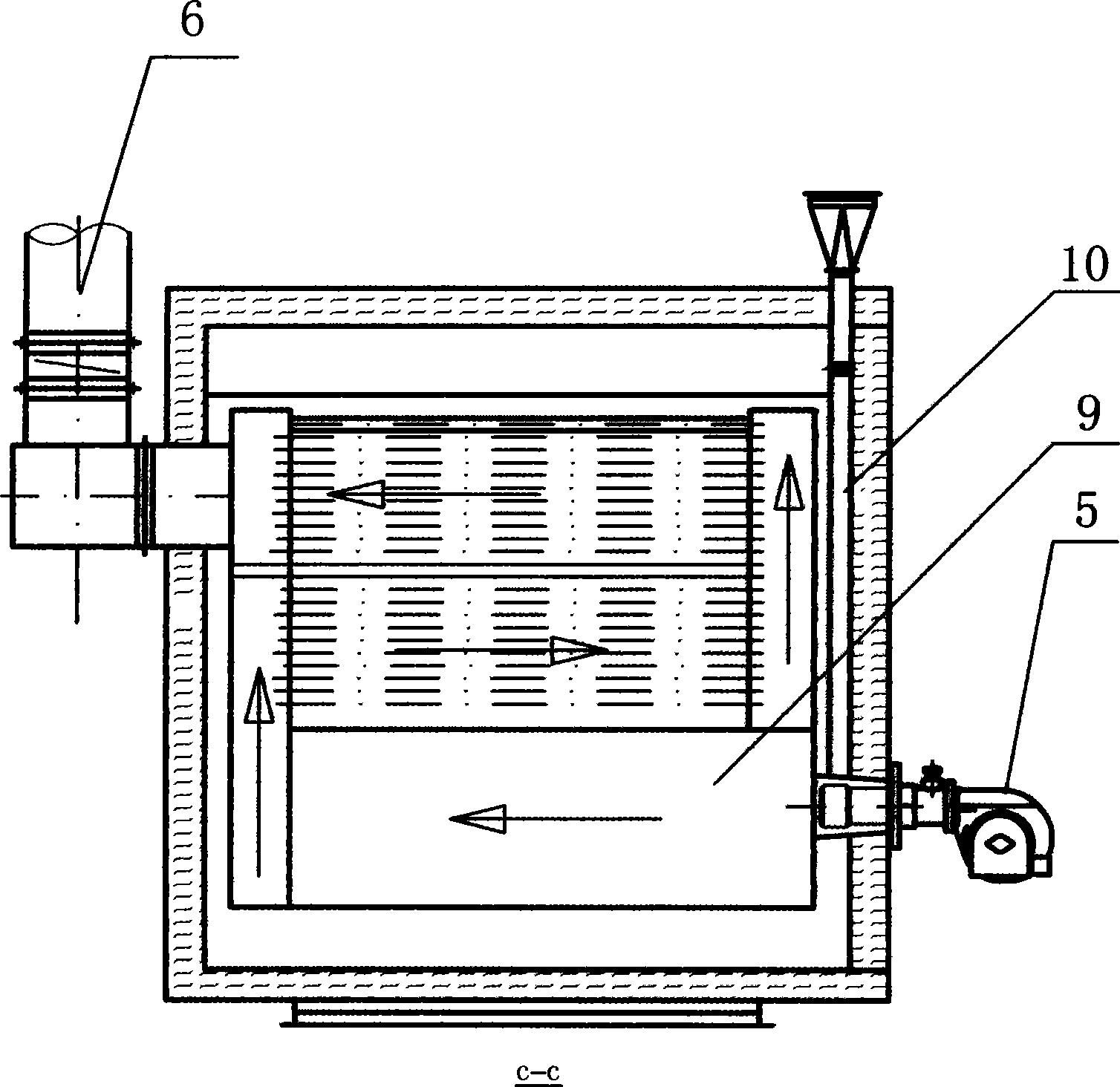

[0013] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

[0014] exist figure 1 and figure 2 Among them, the circulating hot blast stove of the present invention includes a heat preservation chamber body 2, an embedded circulation fan 4, a burner 5, a furnace 9, a heat exchanger 3, and a computer control device. The heat preservation chamber body 2 is set as a hollow cube, and the wall body adopts double layers The structure is filled with insulating material in the middle, with an inspection door 7 on the side, an air inlet 1 at one end, an embedded circulation fan 4 at the other end, a burner 5 on one side of the heat preservation chamber body 2, and a smoke exhaust pipe 6 on the other side , A furnace 9 and a heat exchanger 3 are set in the insulation chamber body 2 cavities.

[0015] The combustion volume of the furnace 9 is relatively large, so that the negative pressure flame formed by the smoke exhaust pipe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap