SOI CMOS image sensor structure and manufacturing method thereof

A technology of image sensor and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, radiation control devices, electrical components, etc., can solve the problems of increasing silicon film, reducing light absorption efficiency, limiting the thickness of photodiode depletion layer, etc., and achieving low Soft error probability, effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0050] Specific embodiment one, such as Figure 4a , Figure 4b ~ Figure 10 Shown:

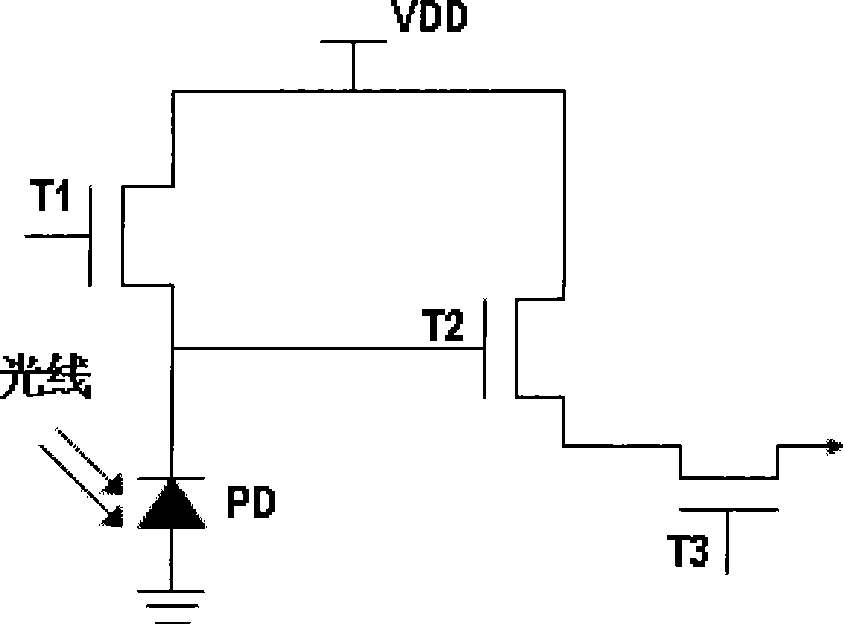

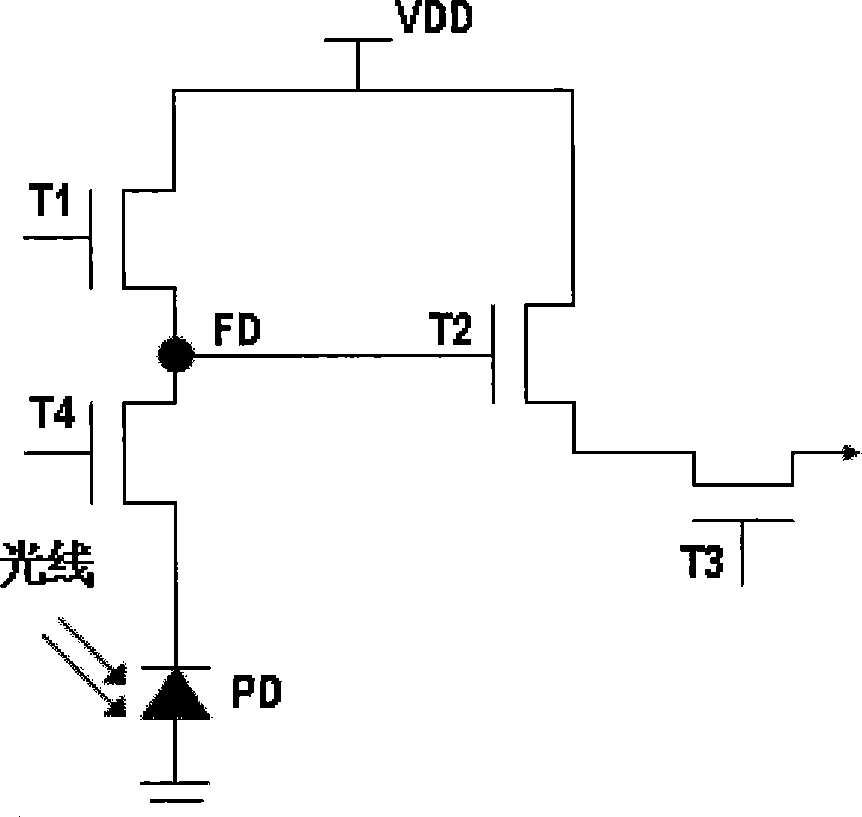

[0051] The following takes 3T-type pixels as an example to illustrate its implementation steps. image 3 A-A' cross-sectional view in a to illustrate, including steps:

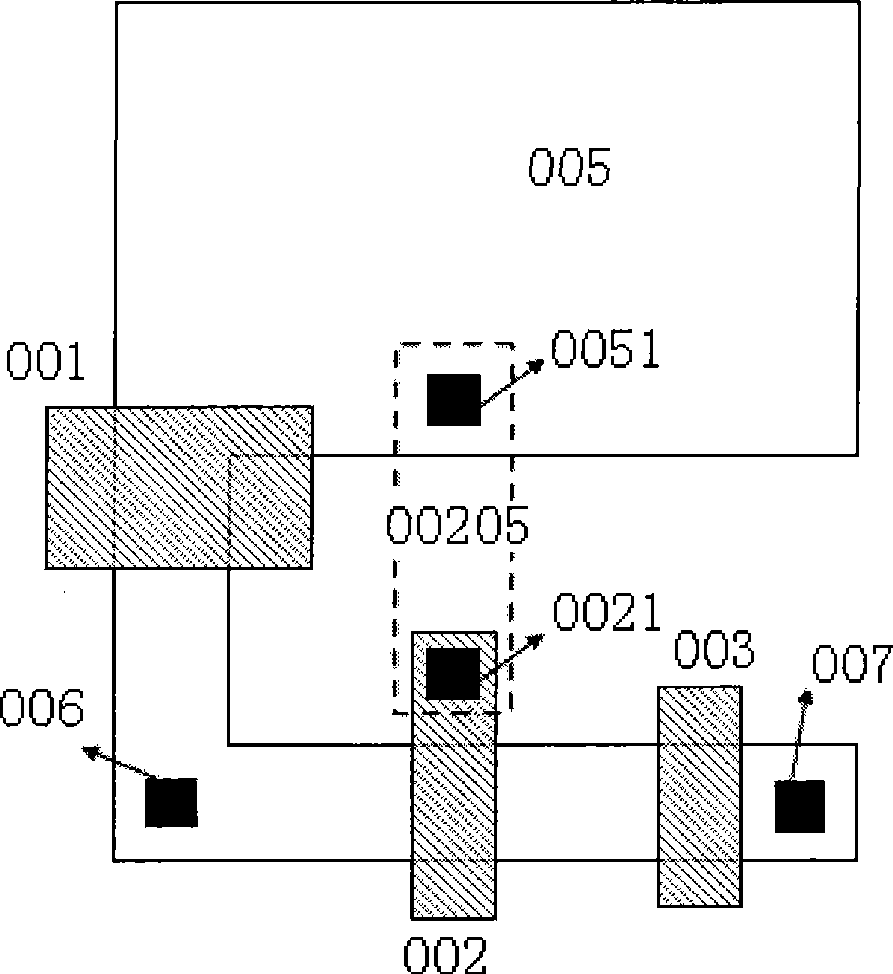

[0052] The first is the selection or preparation of SOI materials, Figure 4aThe SOI material structure is schematically shown, including a silicon substrate 01 , a buried oxide layer 02 and a silicon film 03 . The SOI material can be made by oxygen injection isolation technology (SIMOX, Seperation by Implantation of Oxygen), hydrogen injection bonding technology (Smart-Cut), oxygen injection bonding technology or common bonding technology. The silicon substrate 01 can be P-type silicon, or epitaxial P-type lightly doped silicon 01b on P-type heavily doped silicon 01a;

[0053] Such as Figure 4b As shown, the thickness of the epitaxial layer P-type silicon 01b is 1-10um, the doping concentration is 1E13-5E15, and the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com