Heat generation body cooling structure and drive device

A driving device and heating element technology, applied in cooling/ventilation devices, cooling/ventilation/heating transformation, electromechanical devices, etc., can solve the problems of large-scale coolant pump energy loss, large pressure loss, insufficient heat dissipation, etc. Achieve good cooling capacity, good heat dissipation capacity, and lengthen the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

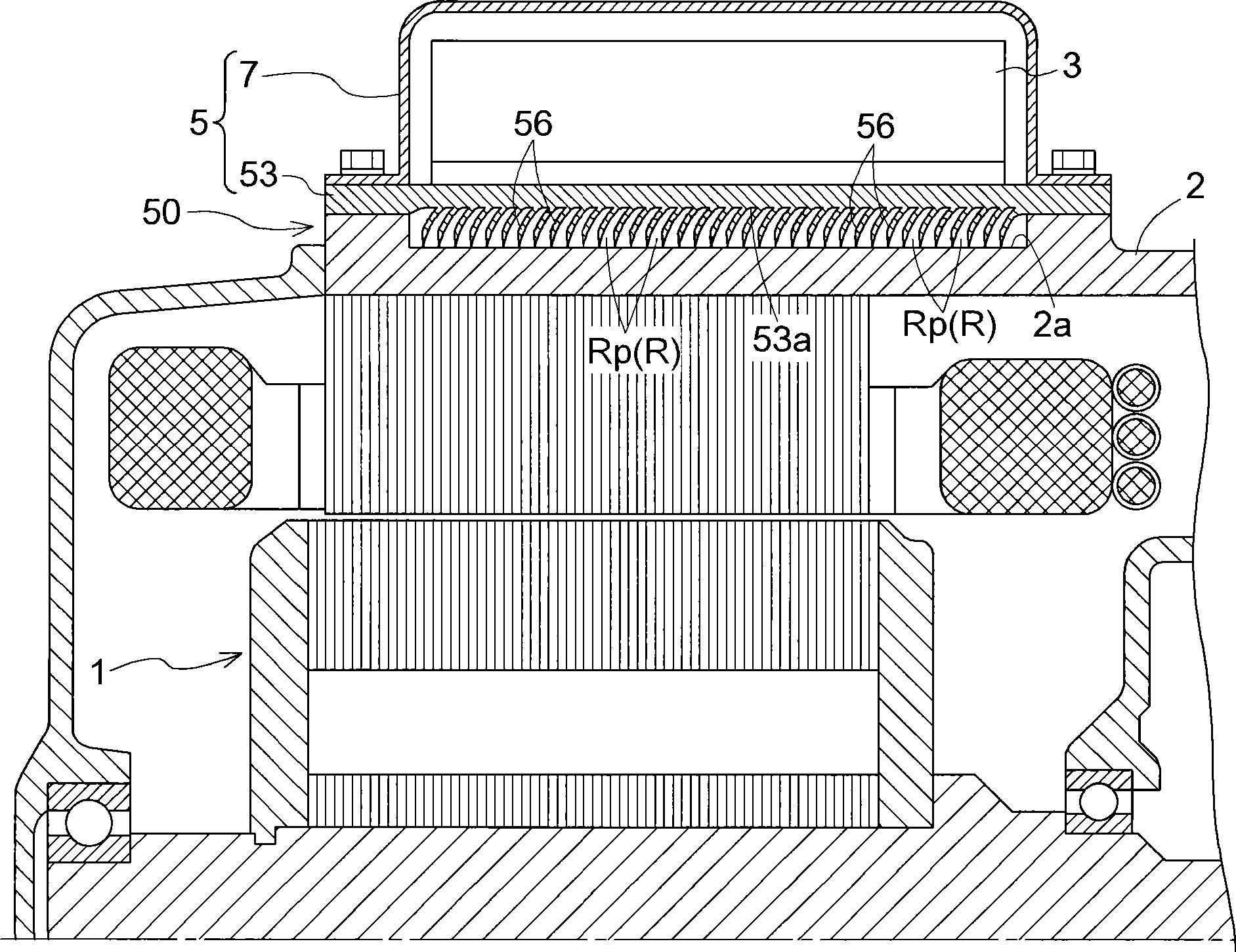

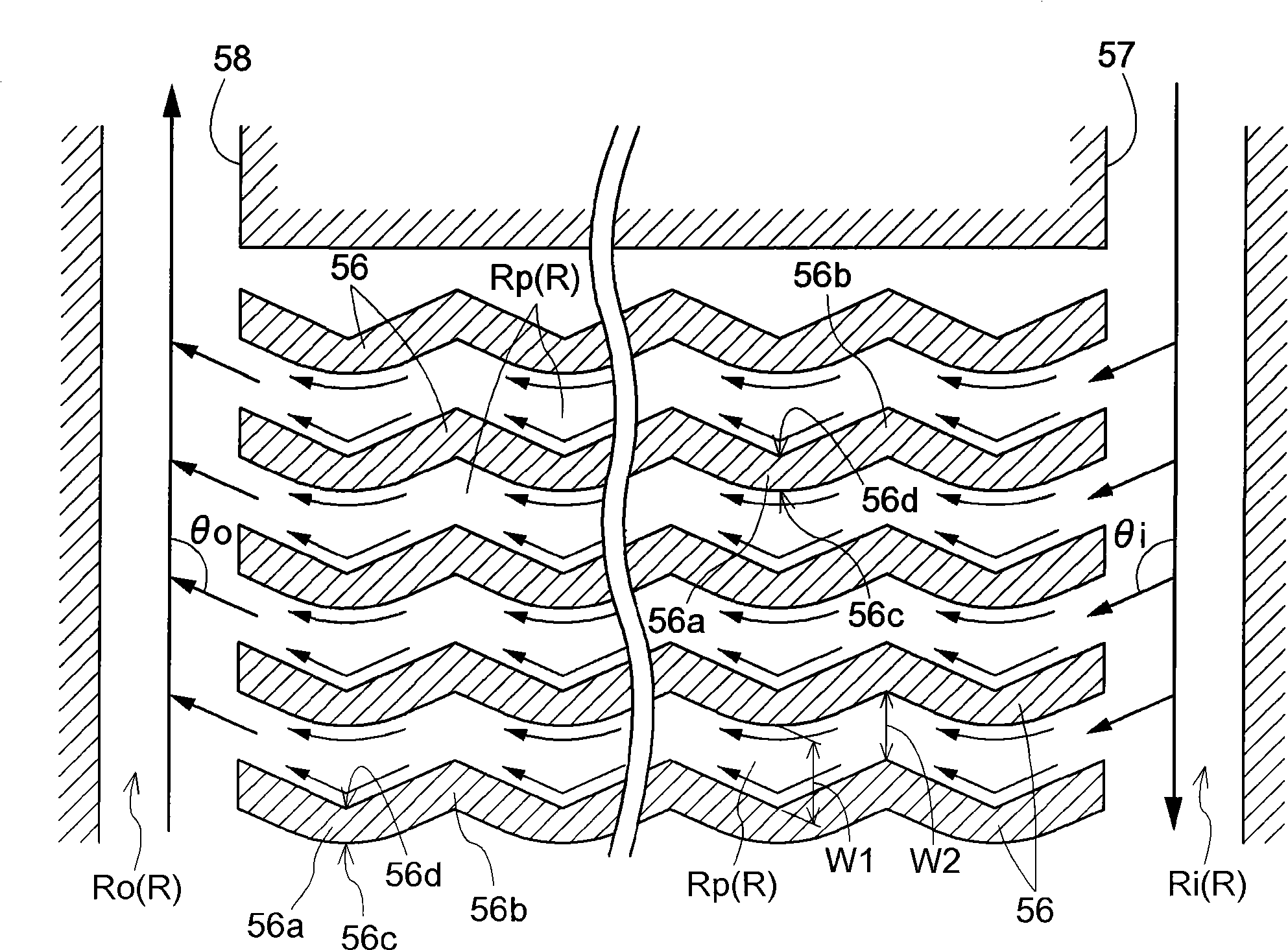

[0060] Embodiments of the heating element cooling structure and the driving device including the structure according to the present invention will be described based on the drawings.

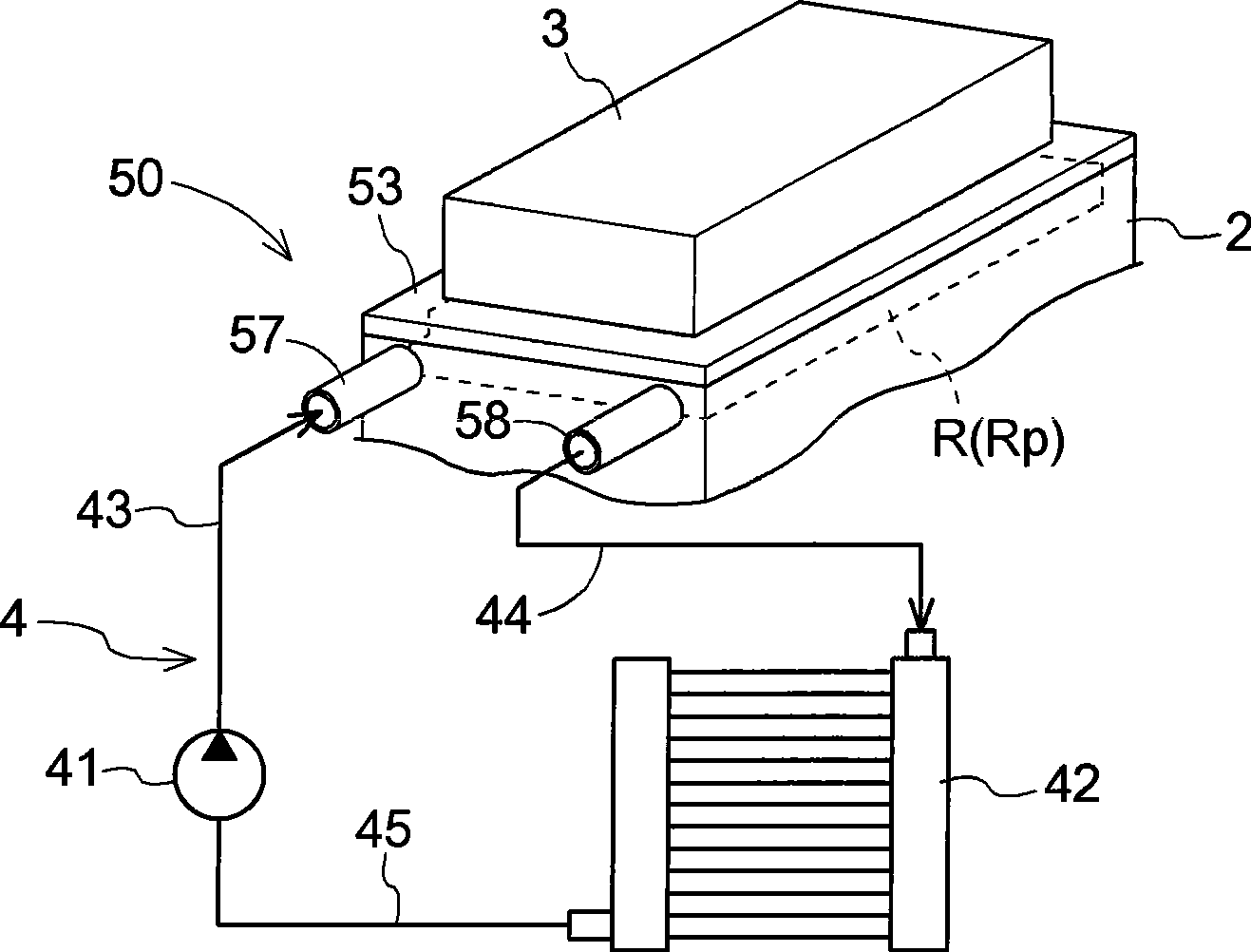

[0061] Such as figure 2 As shown, the driving device (hereinafter referred to as "this driving device") to which the present invention is applied includes: a motor 1, a driving device housing 2 for accommodating the motor 1, an inverter 3 for controlling the motor 1, and adopts the The heating element cooling structure 50 (hereinafter, referred to as "this cooling structure") of the present invention.

[0062] In addition, this driving device constitutes a driving device used in an electric vehicle, a hybrid vehicle, or the like. Therefore, the drive device housing 2 accommodates an electric motor or a generator or both of them as the electric motor 1 , a differential device, an auxiliary mechanism such as a counter gear mechanism, and the like.

[0063] On the other hand, this cooling struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com