Coarse coal powder permanent magnet dry type echelon magnetic extractor

A technology of magnetic separator and coarse coal powder, which is applied in the direction of high-gradient magnetic separator, etc., can solve the problems of high energy consumption, many links involved, and large space required for electromagnetic separation, so as to achieve easy maintenance and improve service life. selection effect, equipment manufacturing and operation cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

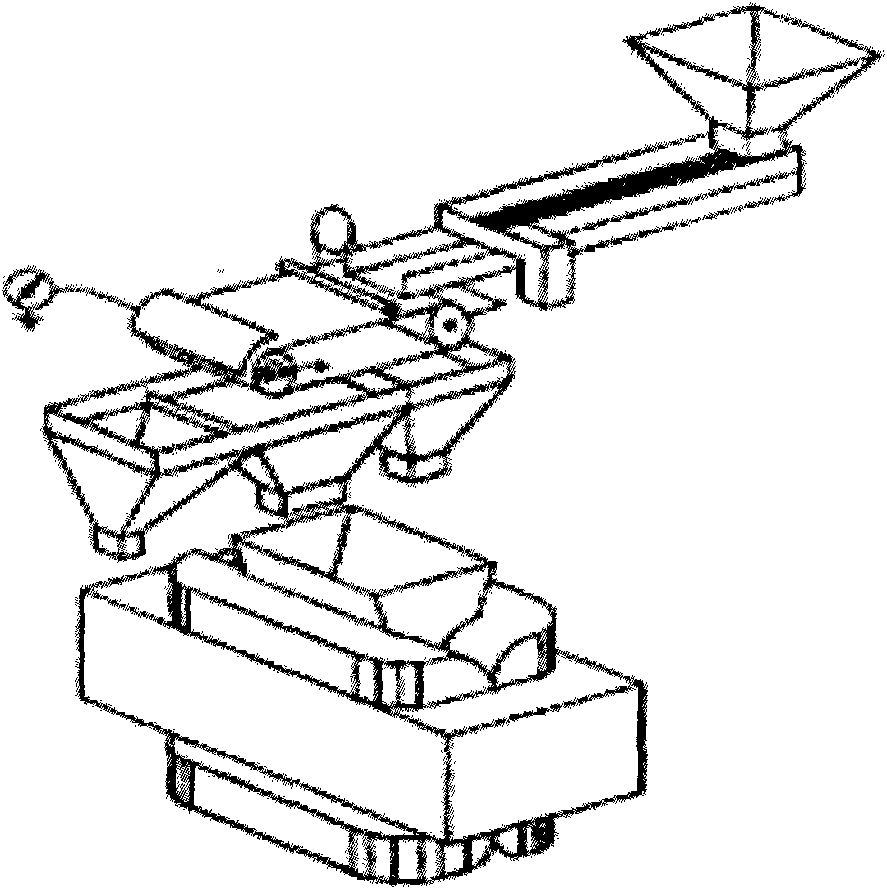

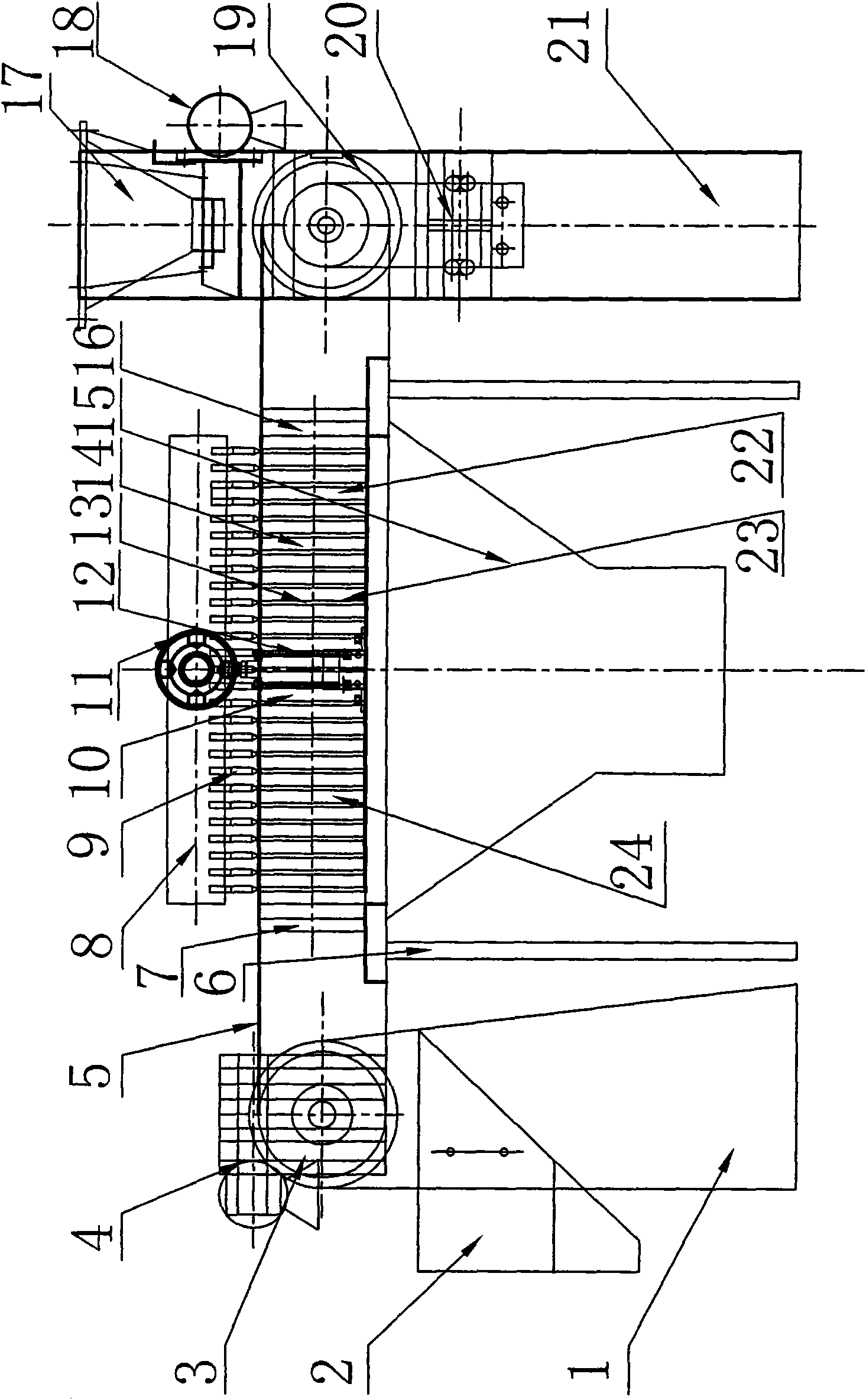

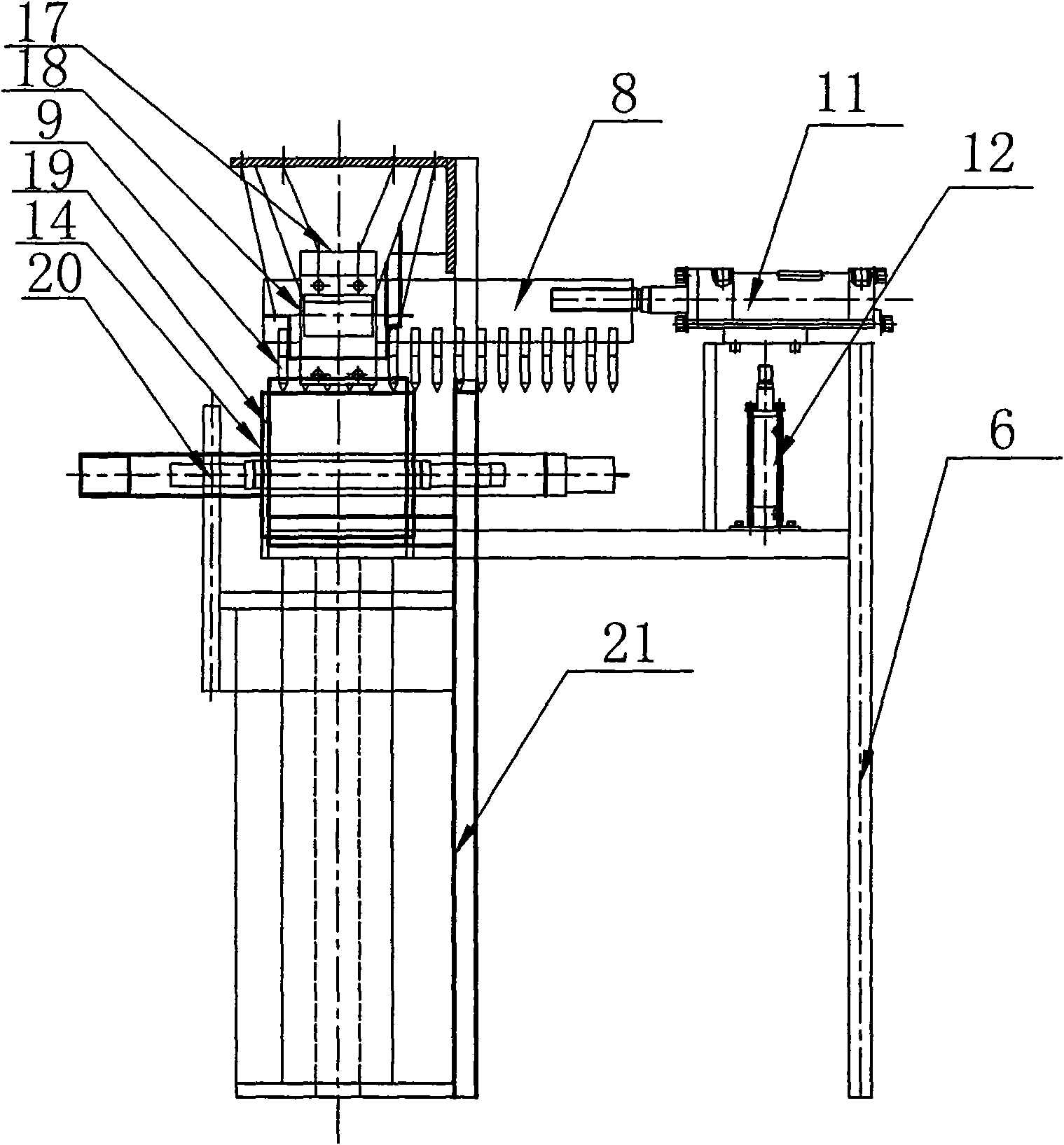

[0027] Such as figure 2 , 3, 4, the coarse coal powder permanent magnet dry-type cascade magnetic separator of the present invention comprises the main body frame 6, is respectively arranged on the left and right sides of the main body frame and is provided with the active conveyor pulley 21 on its frame body. Wheel frame 1 and the driven wheel frame 21 that is provided with driven conveyor pulley 3 on its frame body; Ladder magnetic source 10 is installed on the steel plate platform of main body frame, on the steel plate platform of main body frame The bottom surface of the plate is provided with a magnetic object receiving hopper 15; the upper conveyor belt part of the sorting material conveyor belt driven by the driving conveyor pulley 3 and the driven conveyor pulley 19 is located directly above the step magnetic source 10, and the lower return belt part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com