High-efficiency beet sugar-manufacturing wastewater treatment system

A waste water treatment system, beet technology, applied in food industry waste water treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as failure to meet discharge standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

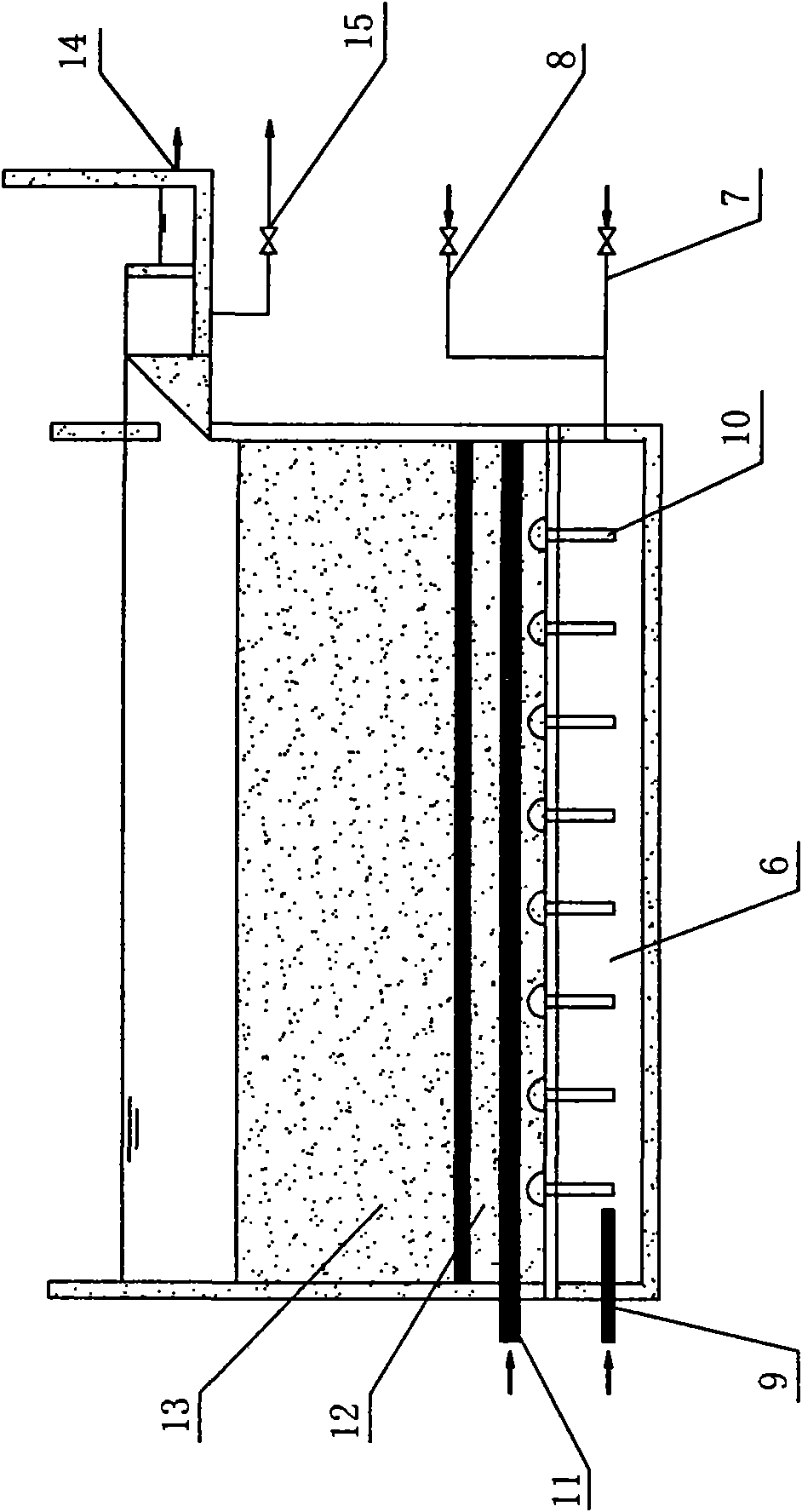

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] The present invention aims at the characteristics of the three high levels (high COD, high BOD, and high SS) of beet sugar factory wastewater, and adopts a combination process combining physicochemical and biochemical processes to pass the sugar beet sugar wastewater after desanding and sedimentation through the exhaust Oxygen baffle reactor and biological aerated filter, so that the quality of the treated effluent reaches the first-level standard of the comprehensive sewage discharge standard (GB8978-1996), that is, the chemical oxygen demand (COD) ≤ 100mg / L, five-day biochemical Oxygen demand (BOD 5 )≤30mg / L, suspended solids (SS)≤70mg / L.

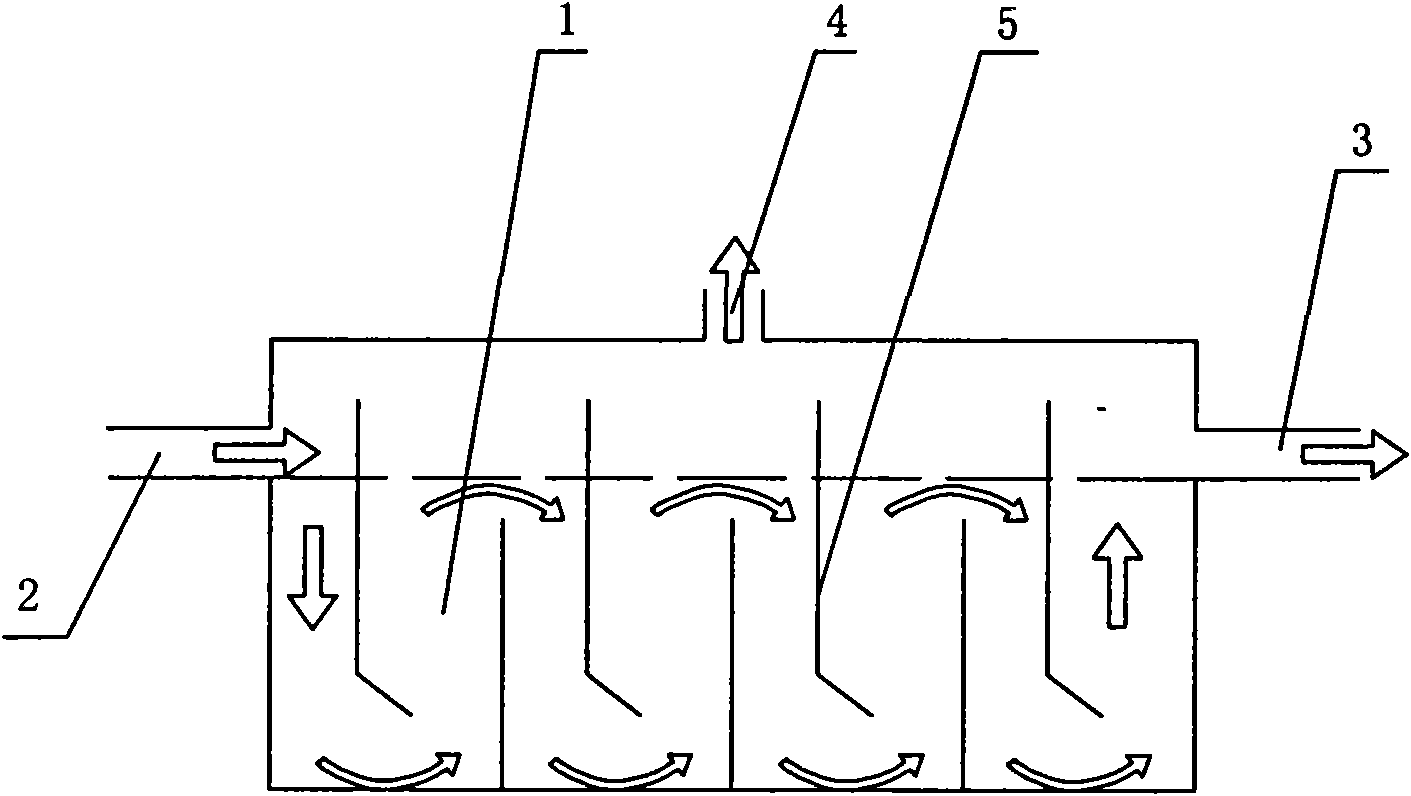

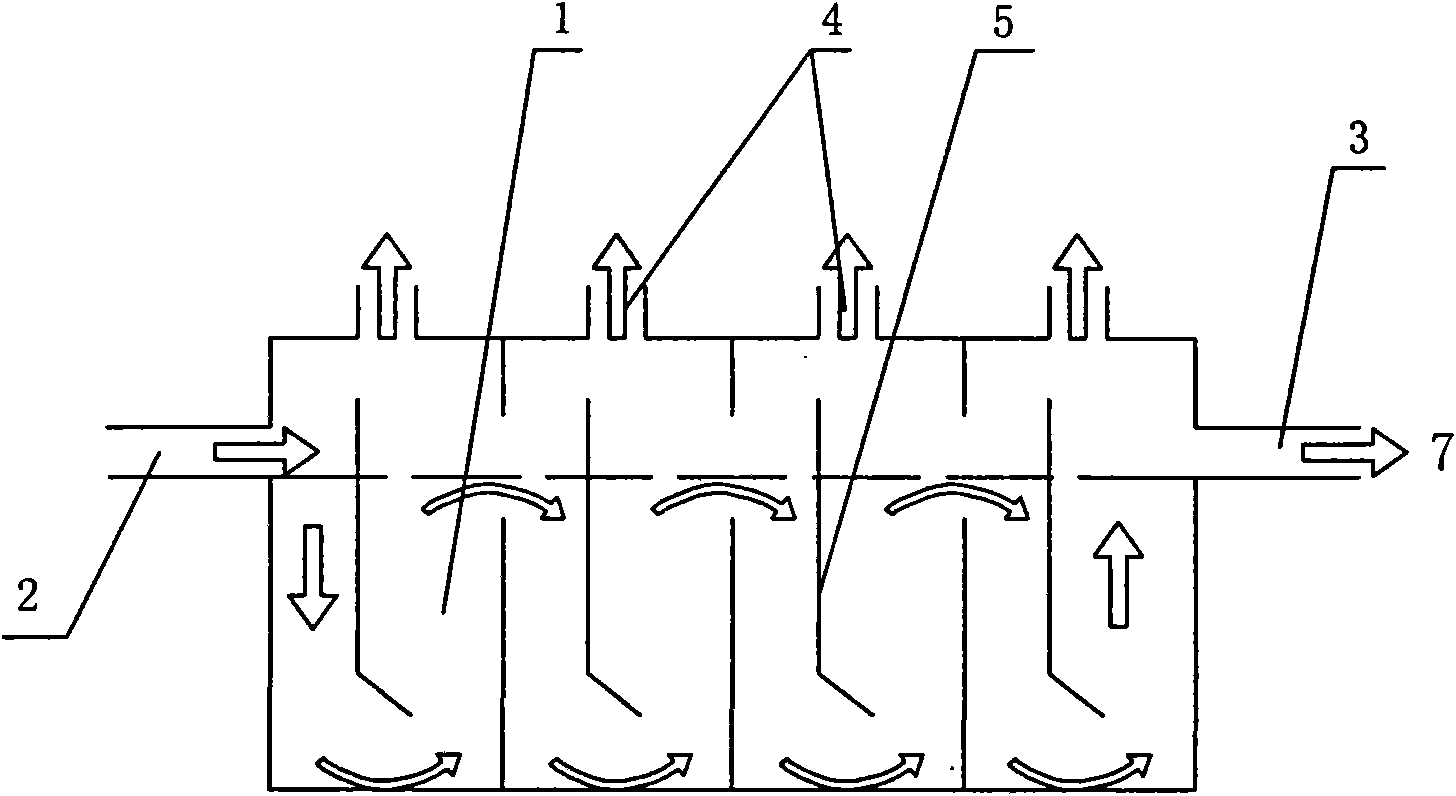

[0023] The anaerobic baffle reactor structure that the anaerobic treatment part of the present invention adopts is as figure 1 , 2 As shown, it is composed of a plurality of reaction chambers 1 connected in series, and adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com