Zinc-nickel alloy nano multilayer film

A nano-multi-layer and multi-layer film technology, which is applied in the field of surface treatment of steel parts and metal materials, can solve the problems of multi-layer film damage, achieve high compactness, high comprehensive performance, and improve production safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

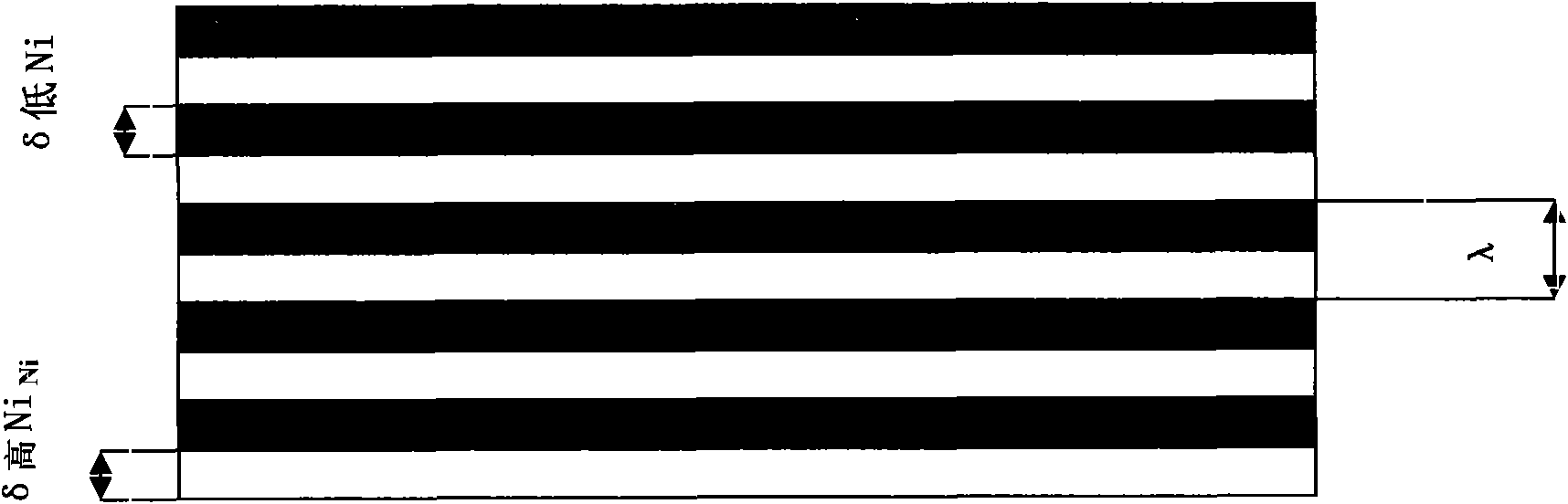

Image

Examples

Embodiment 1

[0016] Embodiment 1: the steel plate that surface is coated with zinc-nickel alloy nano multilayer film, its coating is zinc nickel alloy nano multilayer film, the nickel content of low nickel layer is 14.07%, the nickel content of high nickel layer is 14.07% by weight in the coating The content is 77.35%, and the thickness of the coating is 8.0×10 -3 mm.

[0017] The specific steps are: before the steel plate is electroplated, the parts are polished and washed with water, degreased, then washed with water, rust removed, put into the electroplating bath after washing, and the electrolyte is stirred or left standing, After electrolysis, the parts are taken out from the electrolytic solution, washed with water, and dried. The pH value of the plating solution is 3.5, the power supply mode of plating is pulse output power supply, the temperature is room temperature, and the time is 25 minutes.

[0018] The electrolyte solution contains Ni and Zn salts as the main salt, and NH as...

Embodiment 2

[0019] Embodiment 2: the nut that the surface is coated with zinc-nickel alloy nano-multilayer film, its coating is zinc-nickel alloy nano-multilayer film, the nickel content of low nickel layer is 14.20% by weight in the coating, the nickel of high nickel layer The content is 76.8%, and the thickness of the coating is 7.5×10 -3 mm.

[0020] The surface electroplating method of the nut comprises that the nut is polished and washed with water and degreased before the electroplating, then washed with water, derusted, put into the electroplating solution of the electroplating tank after being washed with water, and the electrolytic solution is stirred Or let it stand still, and after electrolysis, take out the parts from the electrolyte, wash them with water, and dry them. The pH value of the plating solution is 3.5, the power supply mode of plating is pulse output power supply, the temperature is room temperature, and the time is 20 minutes.

[0021] The electrolyte solution c...

Embodiment 3

[0022]Embodiment 3: the pump chamber lining with zinc-nickel alloy nano-multilayer film on the surface, the coating is zinc-nickel alloy nano-multilayer film, and the nickel content of the low-nickel layer in the coating is 13.9% by weight, and the high-nickel layer is 13.9% by weight. The nickel content is 77.5%, and the thickness of the coating is 8.5×10 -3 mm.

[0023] The surface electroplating method for the lining of the pump chamber comprises the steps of polishing, washing, and degreasing the parts and components of the pump chamber lining before electroplating, then washing with water, removing rust, and then placing it into the electroplating solution of the electroplating tank after washing with water, and adding The electrolyte solution is stirred or left to stand, and after electrolysis, the parts are taken out from the electrolyte solution, washed with water, and dried. The pH value of the plating solution is 3.5, the power supply mode for plating is pulse outpu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com