Heat preserving and water proof decoration system for external wall and construction method thereof

A technology for external wall insulation and construction methods, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of poor waterproof performance and easy peeling of layers, so as to prevent alkalization of cement, reduce cleaning difficulty, and avoid The effect of poor bonding and cracking of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

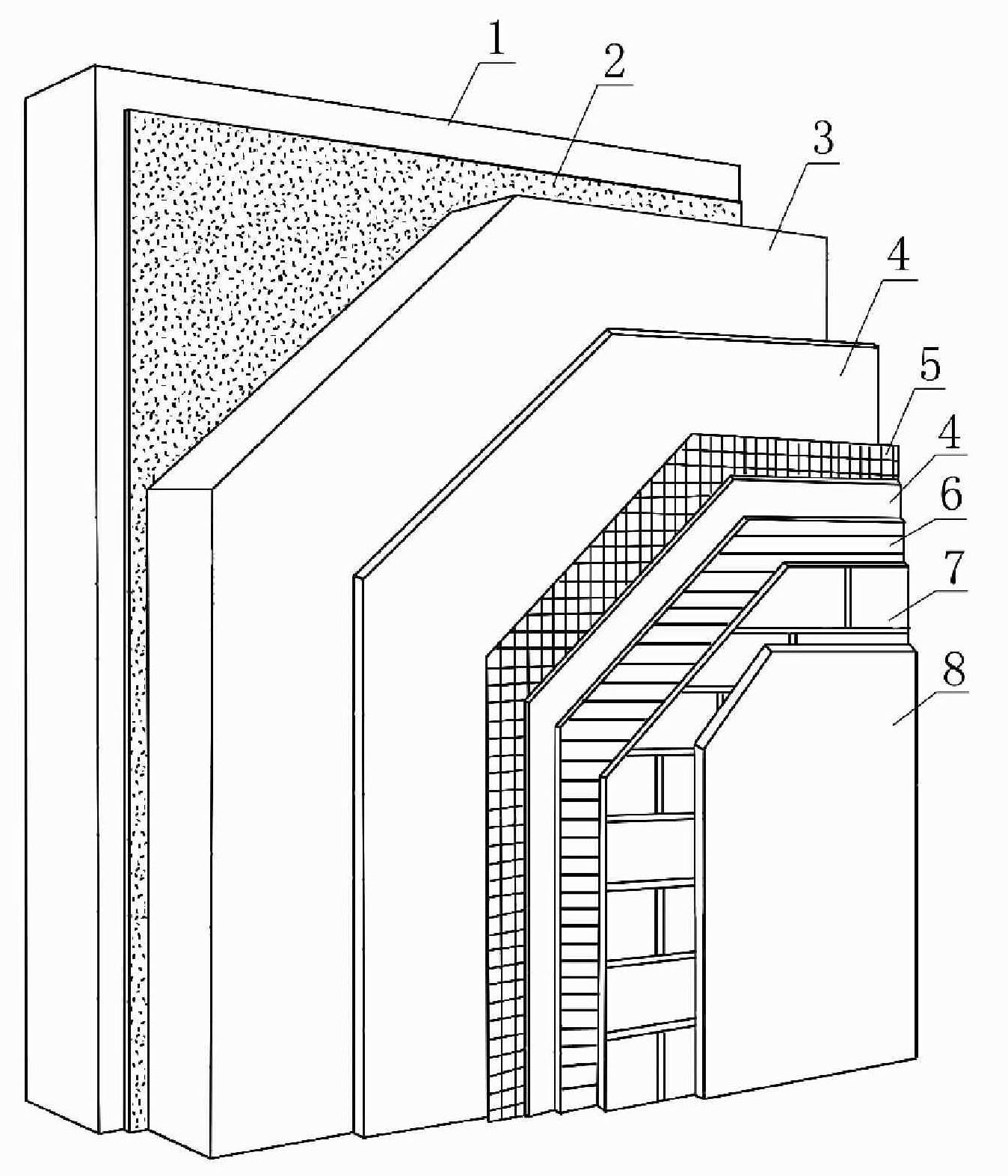

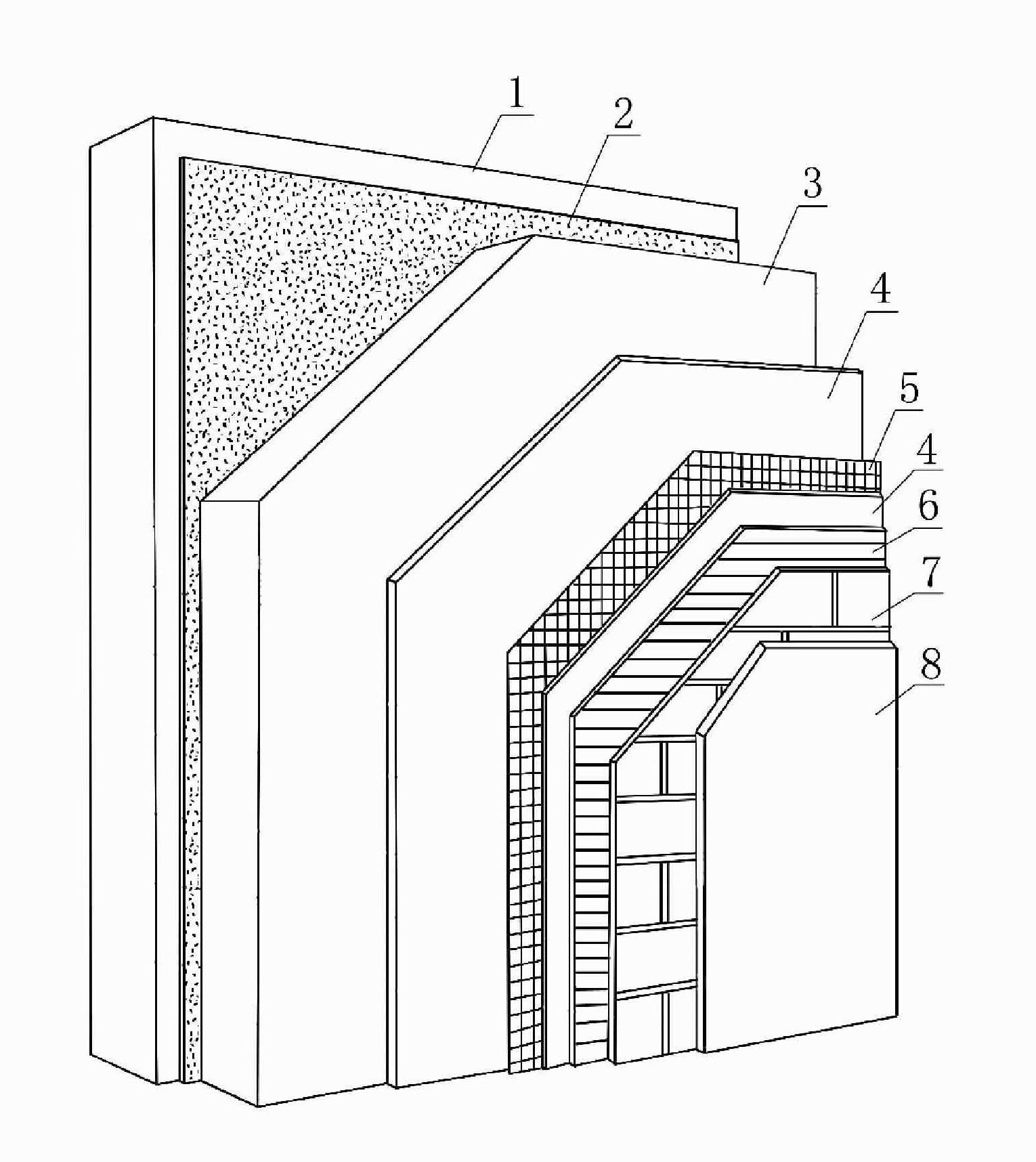

[0026] The embodiment is shown in Fig. 1. This external thermal insulation and waterproof decoration system for external walls includes the thermal insulation layer outside the wall body, and the adhesive mortar layer 2, the thermal insulation layer 3 and the anti-crack mortar layer 4 are fixedly connected in sequence from the wall body 1 to the outside. , the anti-cracking mortar layer 4 is fixedly connected to the outer side of the alkali-resistant waterproof layer 6, the finishing mortar layer 7 and the anti-fouling and waterproof layer 8, wherein the anti-cracking mortar layer 4 is sandwiched with a fiber grid reinforcement layer 5.

[0027] The alkali-resistant and waterproof layer 6 is an alkali-resistant and waterproof layer formed by mixing organic silicon and acrylate series paints, which are existing paints and are available in the market.

[0028] The anti-fouling and waterproof layer 8 is an anti-fouling and waterproof layer formed by mixing organic silicon series c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com