Preparing method of optical substrate hidden pattern

A technology for optical substrates and substrates, applied in optics, optical components, instruments, etc., can solve problems such as environmental pollution and display patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

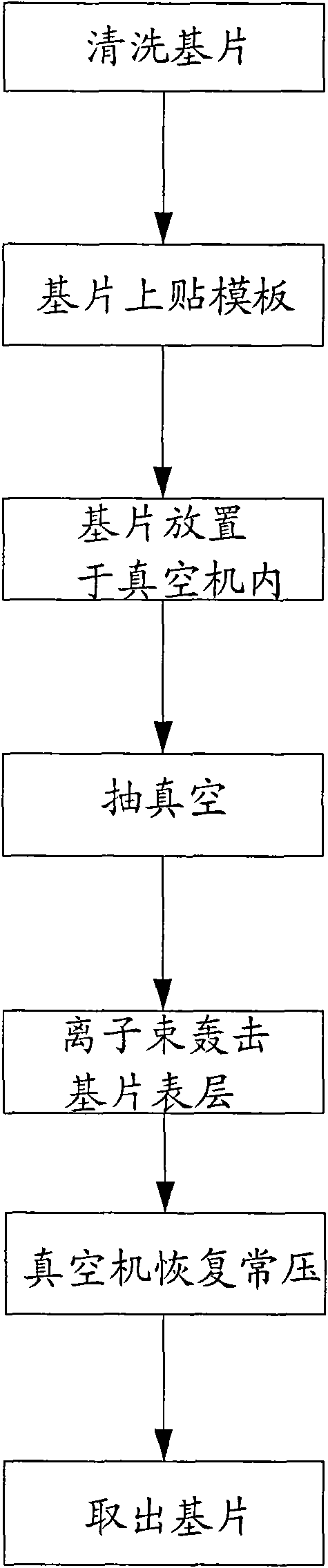

[0015] Example: a structure such as figure 1 As shown, the preparation method of the invisible pattern on the optical substrate, after the substrate is cleaned, the required hollow pattern template is pasted on the substrate, the substrate is fixed on the jig (this is the support for fixing the substrate) and then placed in a vacuum to at least 5*10 -5 In Torr's high-vacuum machine; the surface layer of the substrate in the hollowed out part is bombarded by ion beams to make the surface layer of the hollowed out part thinner. The bombardment time is 3-15 minutes. The thinned part of the substrate has a lower refractive index than other parts, so that Form an invisible pattern on the substrate.

[0016] The ion beam is emitted by the ion gun, the bombardment time is 3-15 minutes, the working current is three-phase, and the voltage is 220v.

[0017] The substrate is any one of acrylic (AC) substrate, polycarbonate (Polycarbonate) substrate, nylon (Nylon) substrate, CR-39 subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com