Machine tool

A technology of machine tools and pallets, applied in the field of machine tools, can solve problems such as long replacement time and complex structure of pallet replacement devices, and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

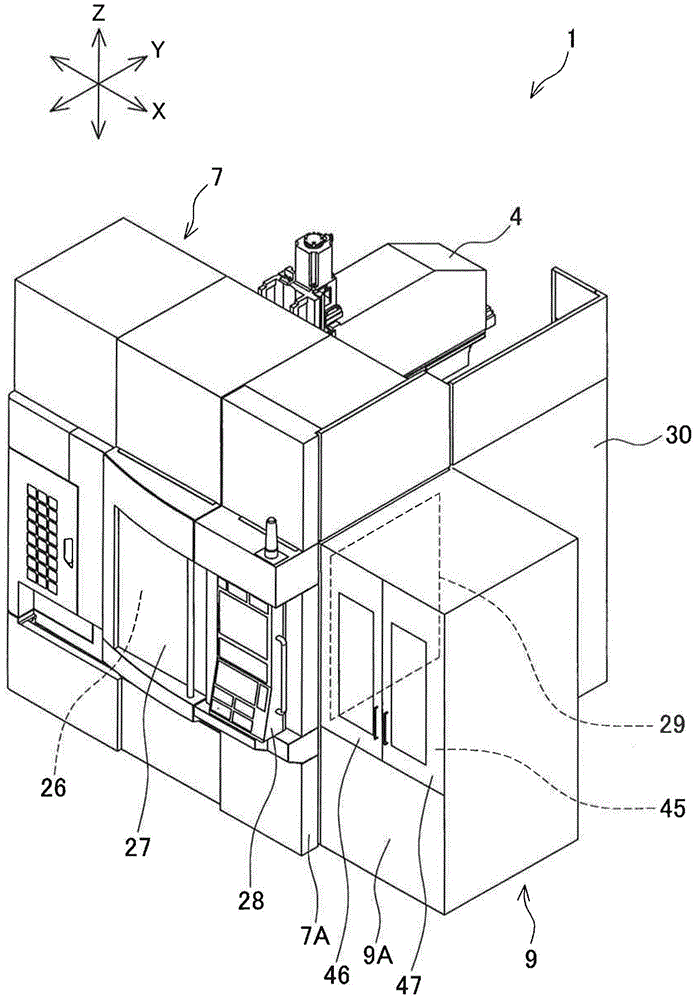

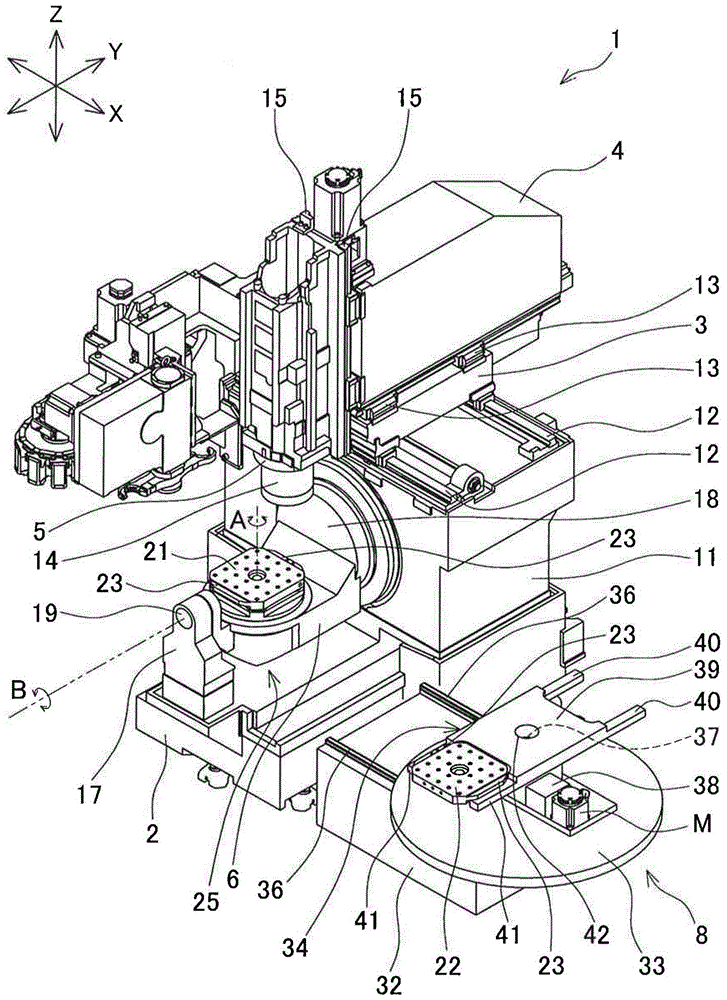

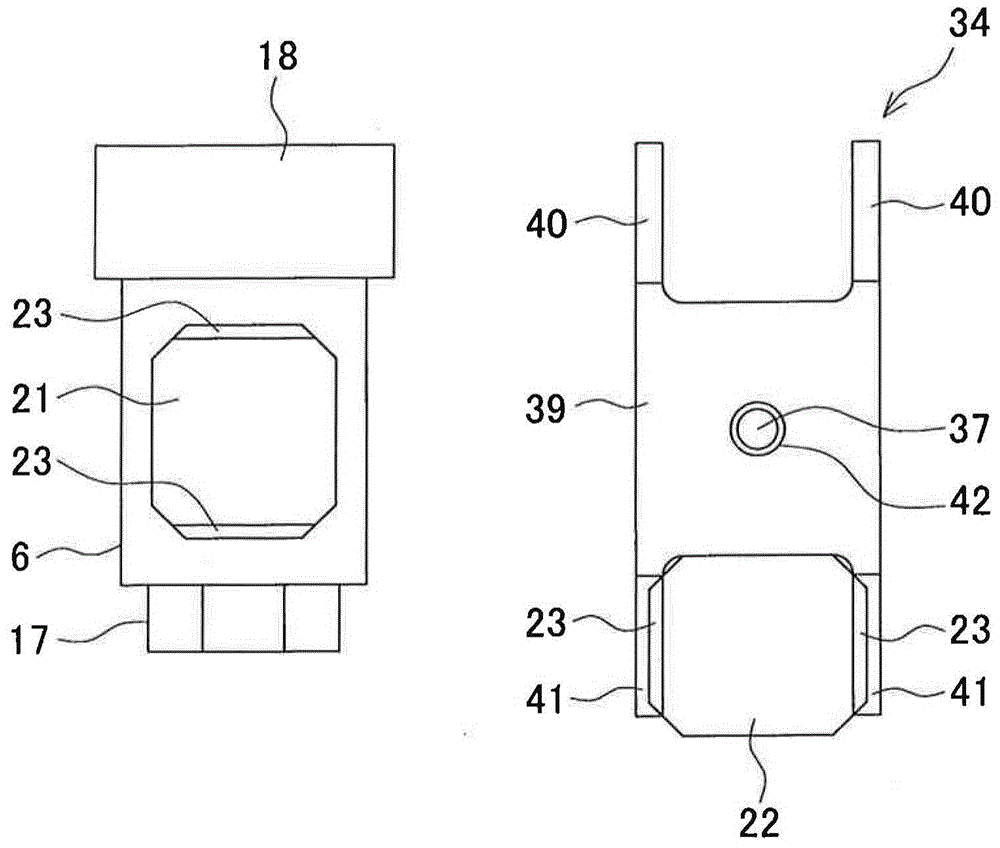

[0044] refer to Figure 1 to Figure 8 Embodiment 1 of the present invention will now be described. figure 1 with figure 2 The shown vertical machining center 1 includes a bed 2 , a saddle 3 , a column 4 , a headstock 5 , a table 6 , a main body cover 7 , a pallet changer 8 , and a side cover 9 . In addition, the vertical machining center 1 is an example of the machine tool of the present invention.

[0045] Such as figure 2 As shown, the bed 2 has a rectangular shape long in the front-rear direction (Y-axis direction) in plan view, and is installed on the floor. On the upper surface of the bed 2 and at the rear end of the bed 2, a rising portion 11 is provided to rise upward. A saddle 3 is provided on the upper surface of the standing portion 11 , and the saddle 3 is guided by the X-axis guide rails 12 , 12 so as to be movable in the left-right direction (X-axis direction). A column 4 is provided on the upper surface of the saddle 3 , and the column 4 is guided by a Y-a...

Embodiment approach 2

[0068] refer to Figure 9 to Figure 14 Embodiment 2 of the present invention will be described. Here, the same reference numerals are assigned to the same configurations as those in the first embodiment, and description thereof will be omitted. This vertical machining center 1A also includes a main body cover 7 and a side cover 9 , which are not shown. Such as Figure 9 As shown, a saddle 3A is provided on the front surface of the standing portion 11, and the saddle 3A is guided by X-axis guide rails 12A, 12A so as to be movable in the X-axis direction. A spindle head 5 is provided on the front surface of the saddle 3A, and the spindle head 5 is guided by Z-axis guide rails 15A, 15A so as to be movable in the Z-axis direction parallel to the axis of the spindle 14 .

[0069] On the upper surface of the bed 2 is provided with Figure 9 with Figure 11 Shown slide table 50, this slide table 50 is by Y-axis guide rail 13A, 13A (referring to Figure 10 ) to move in the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com