Automatic leveling system of multipoint electric support platform

A technology of supporting platform and automatic leveling, applied in electrical program control, control using feedback, and comprehensive factory control, etc., can solve problems such as slow movement, inconsistent pressure, and no safety protection design, and achieve faster speed and structural stability. Reasonable effect of force change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

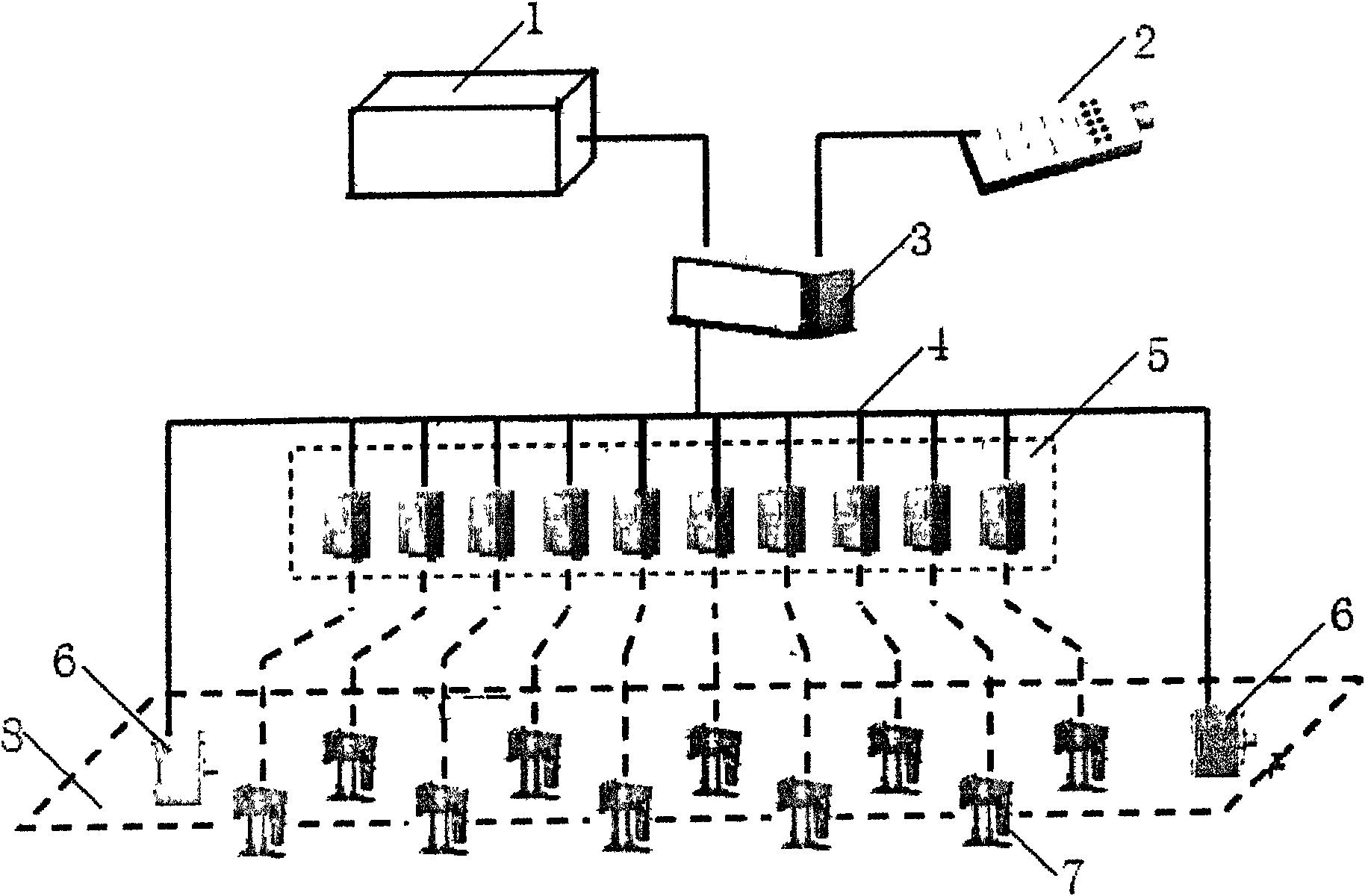

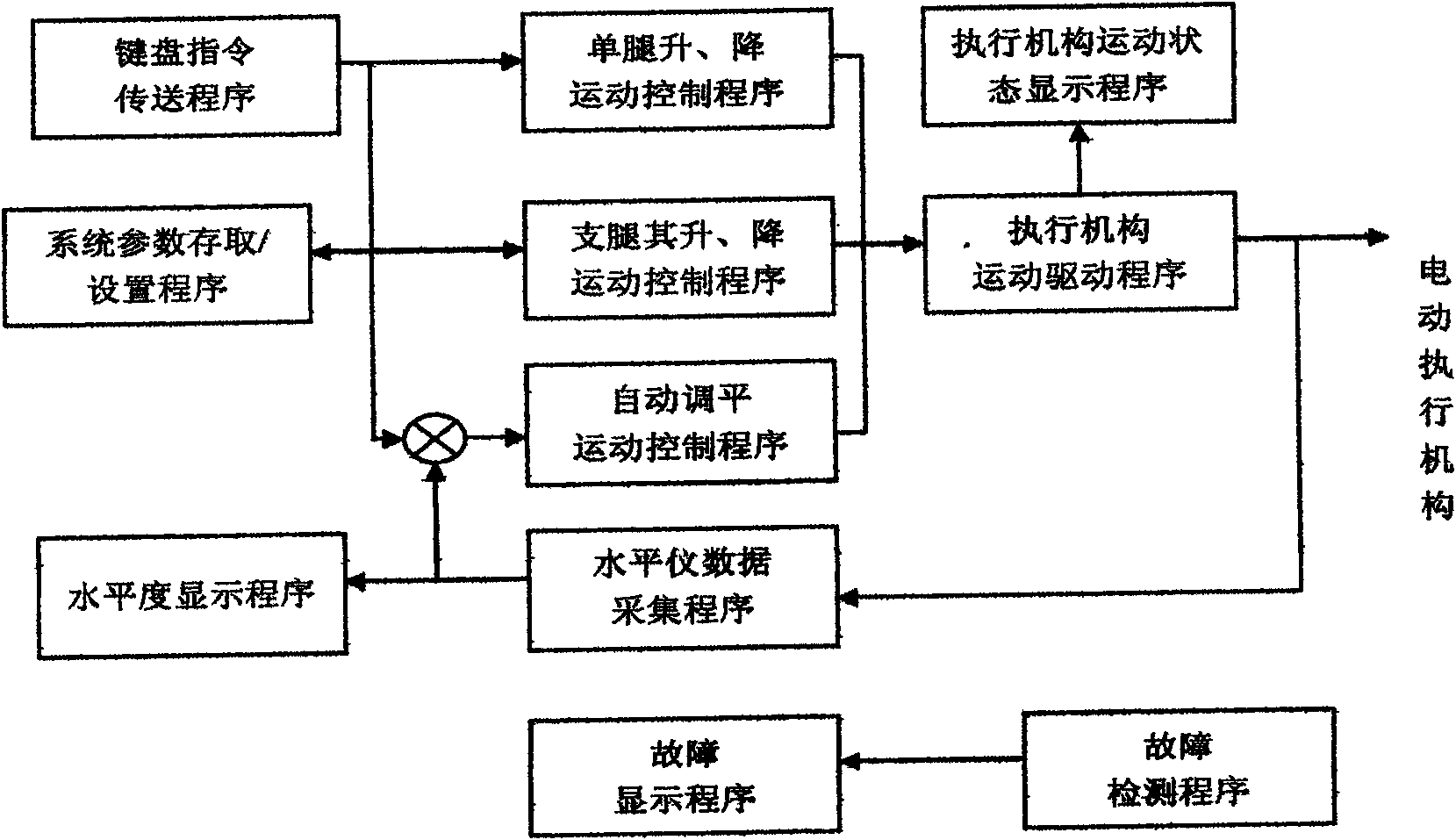

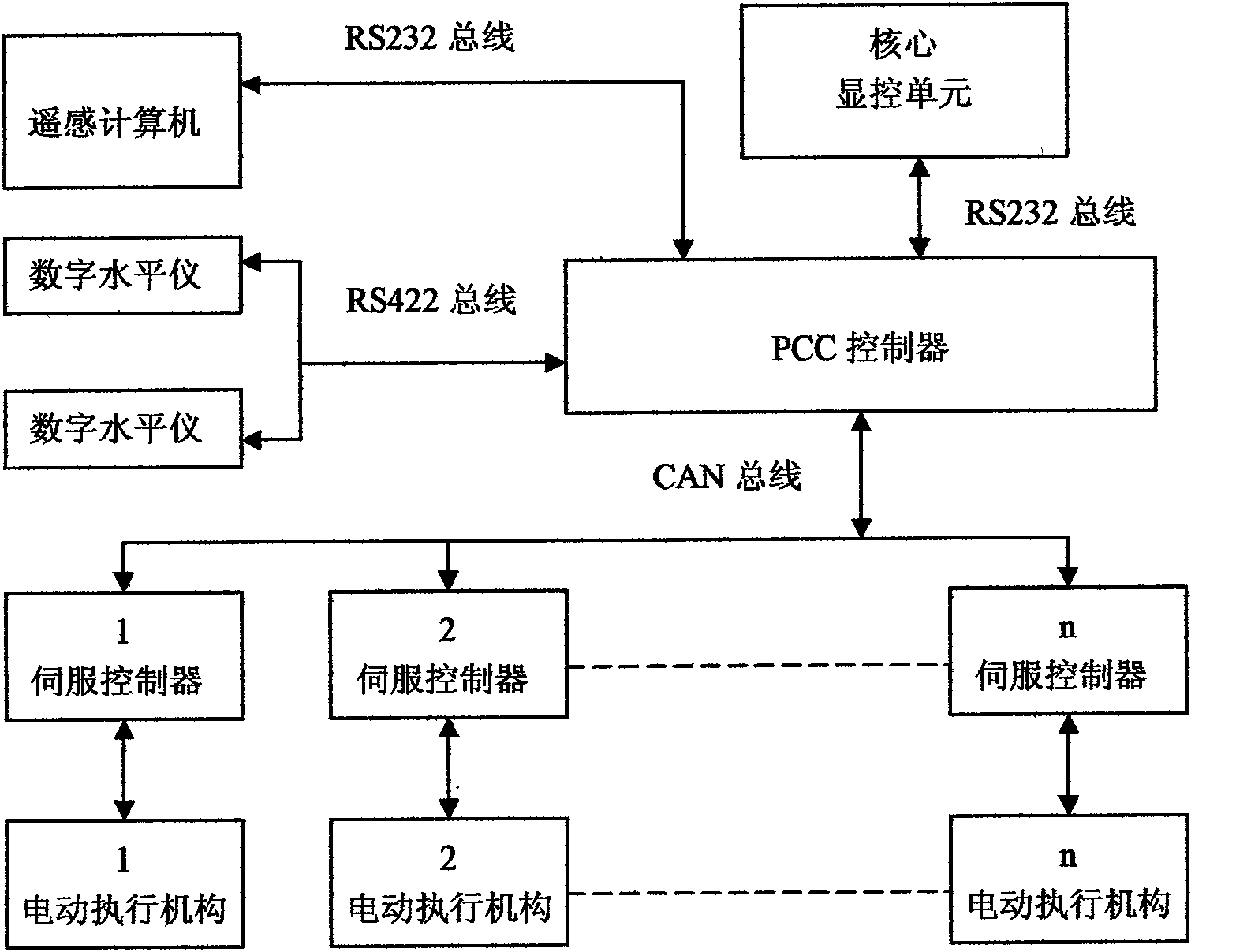

[0030] refer to figure 1, the automatic leveling system of the point electric support platform mainly includes, according to the positions of other interference objects of the vehicle or platform, the dot matrix electric actuator 7 is geometrically distributed on the lower part of the working platform 8 plane; it is located on the working platform 8 plane for A digital level 6 for real-time detection and leveling and monitoring of the deformation of the working platform 8 or vehicle body; a central digital controller 3 composed of a programmable computer PCC controller or PLC control program and hardware driver software; capable of real-time monitoring of system information status and completion The user sets the working parameters, and displays information such as the working status, levelness, extension height of the supporting legs, load bearing of the supporting legs, system fault codes, etc., and has a leveling display and control cabinet with touch screen interface operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com