Stirring transport tank

A technology for stirring, transporting and transporting tanks, applied in the field of transport tanks, can solve the problems affecting the quality of the contents, troublesome maintenance, and difficulty in discharging the contents, and achieve the effects of reducing sediment, good stirring performance and saving working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

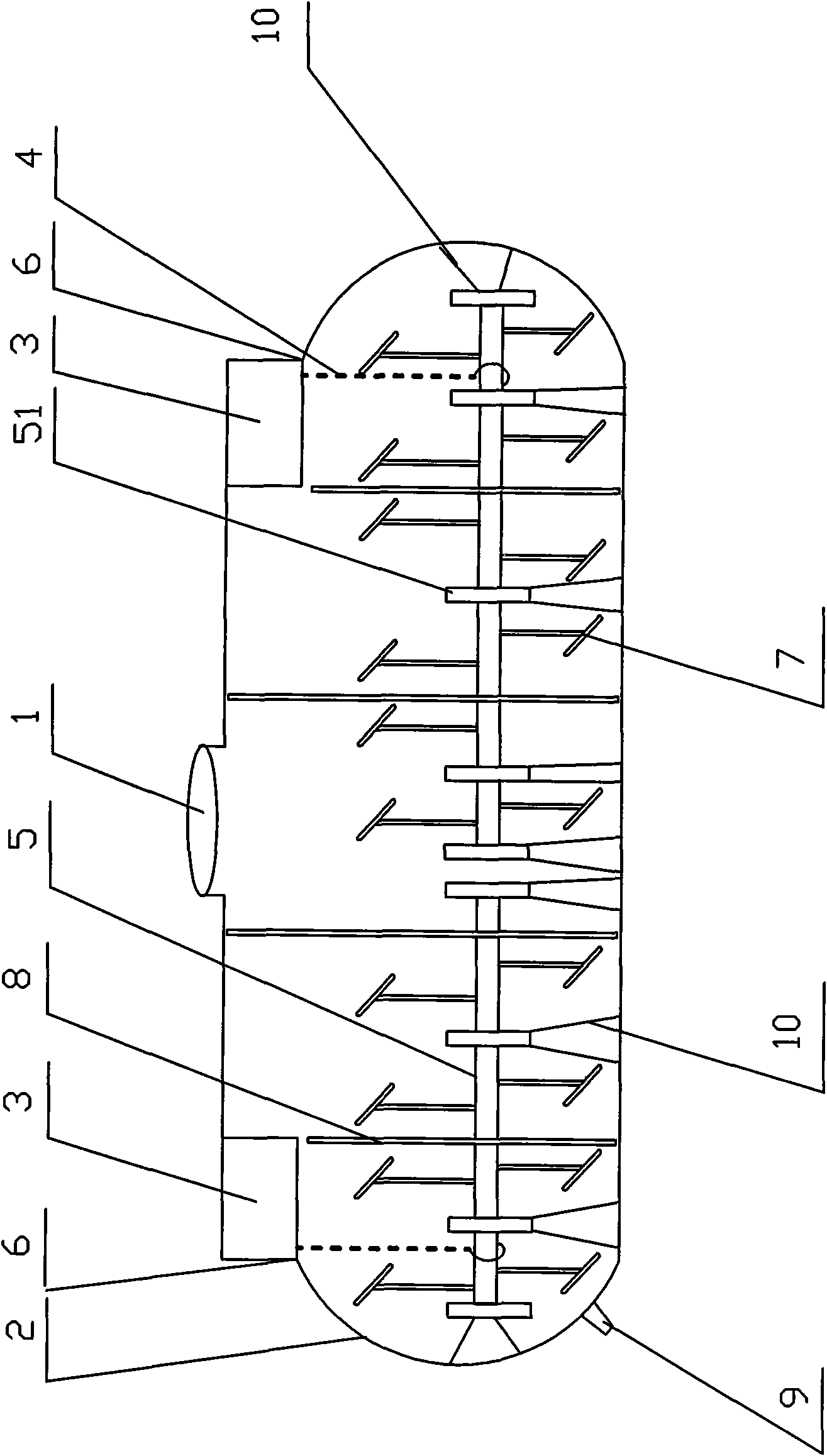

[0039] see figure 1

[0040] figure 1 It is a structural schematic diagram of the present invention. exist figure 1 Among them, the transport tank of the transport vehicle is provided with a stirring device, the stirring device includes a stirring system and a transmission system connected thereto, and the stirring system includes a stirring shaft 5 with a stirring impeller 7 engaged with a bearing sleeve 51, Agitator shaft 5 passes through dividing plate 8 (dividing plate 8 can adopt prior art, can be arched), and described agitating shaft 5 is connected with the transmission system that vehicle adds, and described transmission system comprises gear transmission case 3 and is connected with it Transmission chain 4, described transmission system is connected with the power system of vehicle, also can set up a back-up power supply (backup pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com