Method for separating and purifying C* by using simulated moving bed chromatography

A technology of simulating moving bed and chromatographic separation, which is applied in the field of separation of fullerene-like pure carbon molecules, can solve problems such as no public reports, achieve the effects of reducing production costs, saving mobile phase, and realizing large-scale continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

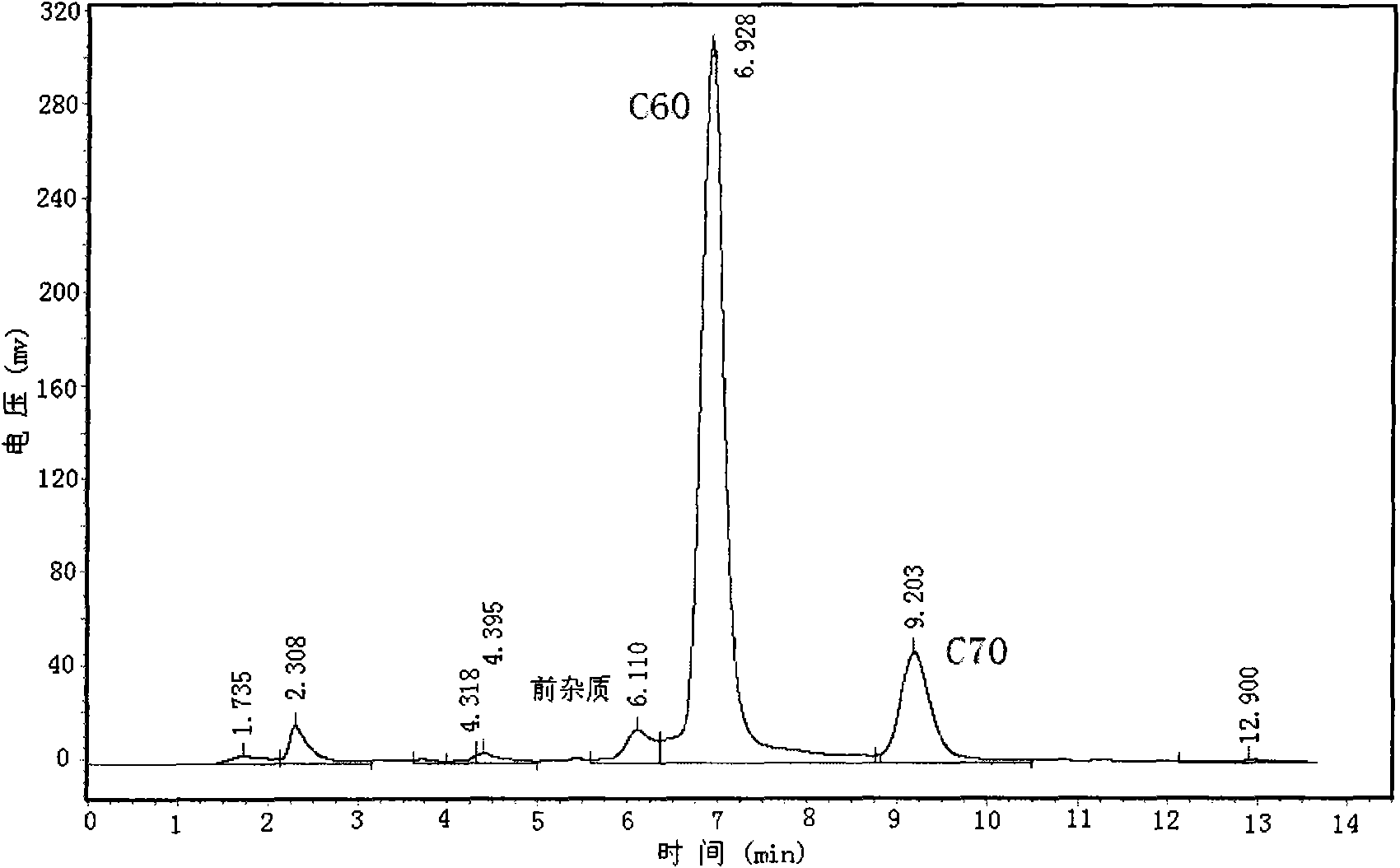

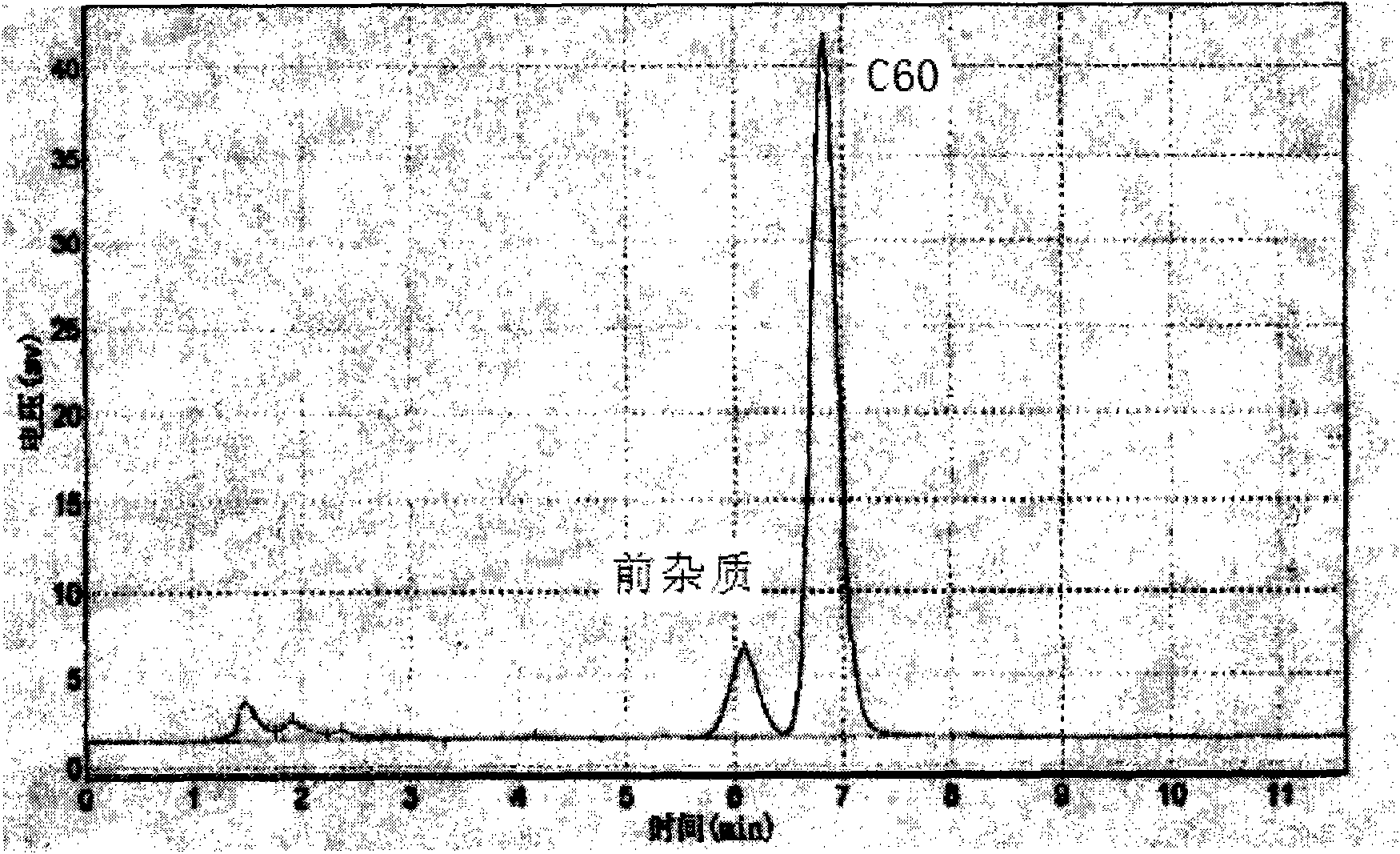

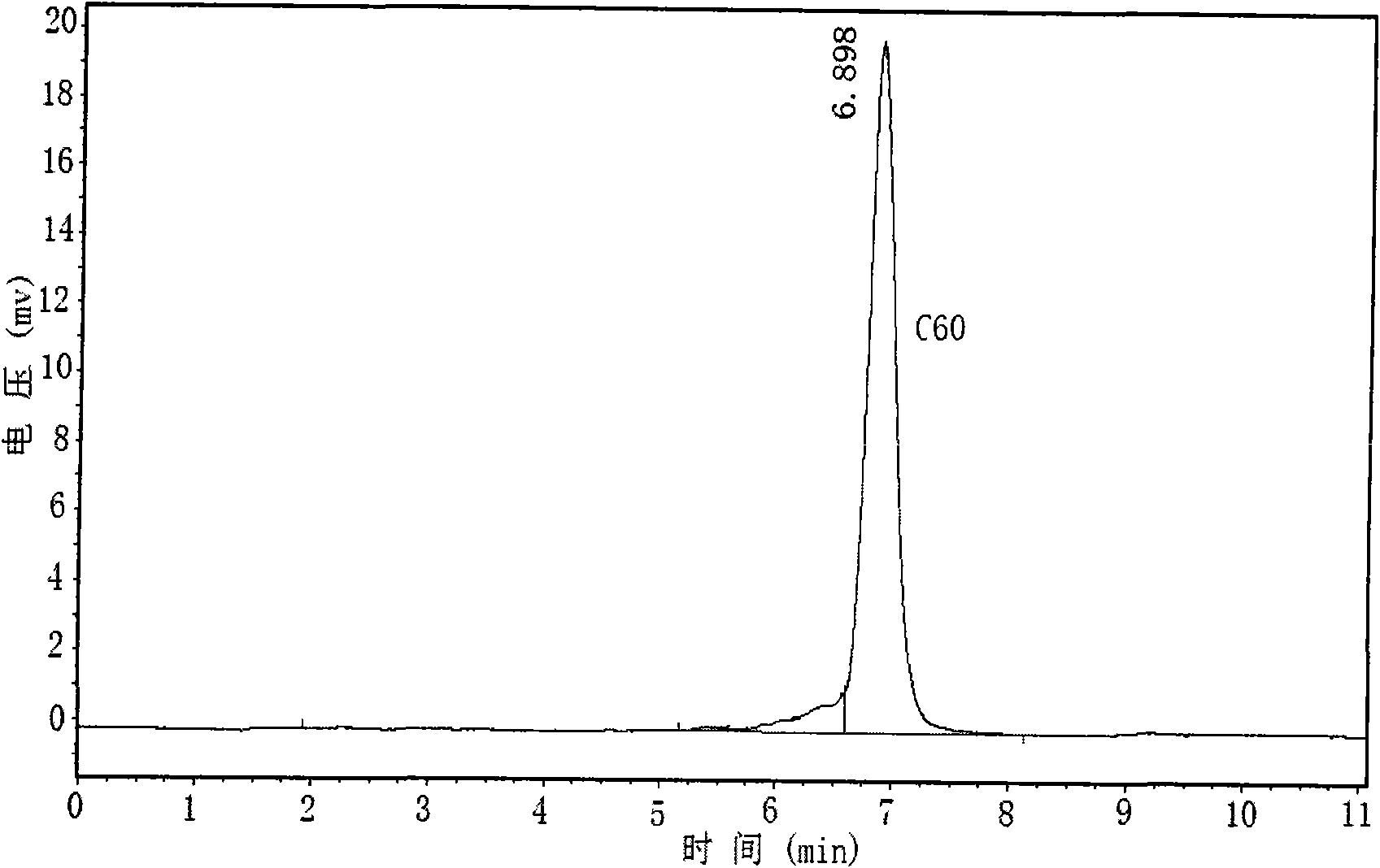

[0033] to purify C 60 Small-scale experiment is example, take 10 milligrams crude fullerene (C 60 Content 80%, C 70 content 10%), dissolved with toluene, sedimentation, 0.45 μm filter membrane filtration, the filtrate is a saturated solution containing thick fullerene, as the separation raw material of simulated moving bed, the HPLC spectrogram of thick fullerene raw material liquid is as follows figure 1 shown. The methanol / toluene mixed solvent was used as the mobile phase, and the purification was carried out with a simulated moving bed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com