Method for separating aqueous phase byproduct from Fischer-Tropsch synthesis reaction

A Fischer-Tropsch synthesis and separation method technology, which is applied in the separation/purification of carboxylic acid compounds, the separation/purification of hydroxyl compounds, the separation/purification of carbonyl compounds, etc. economic, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

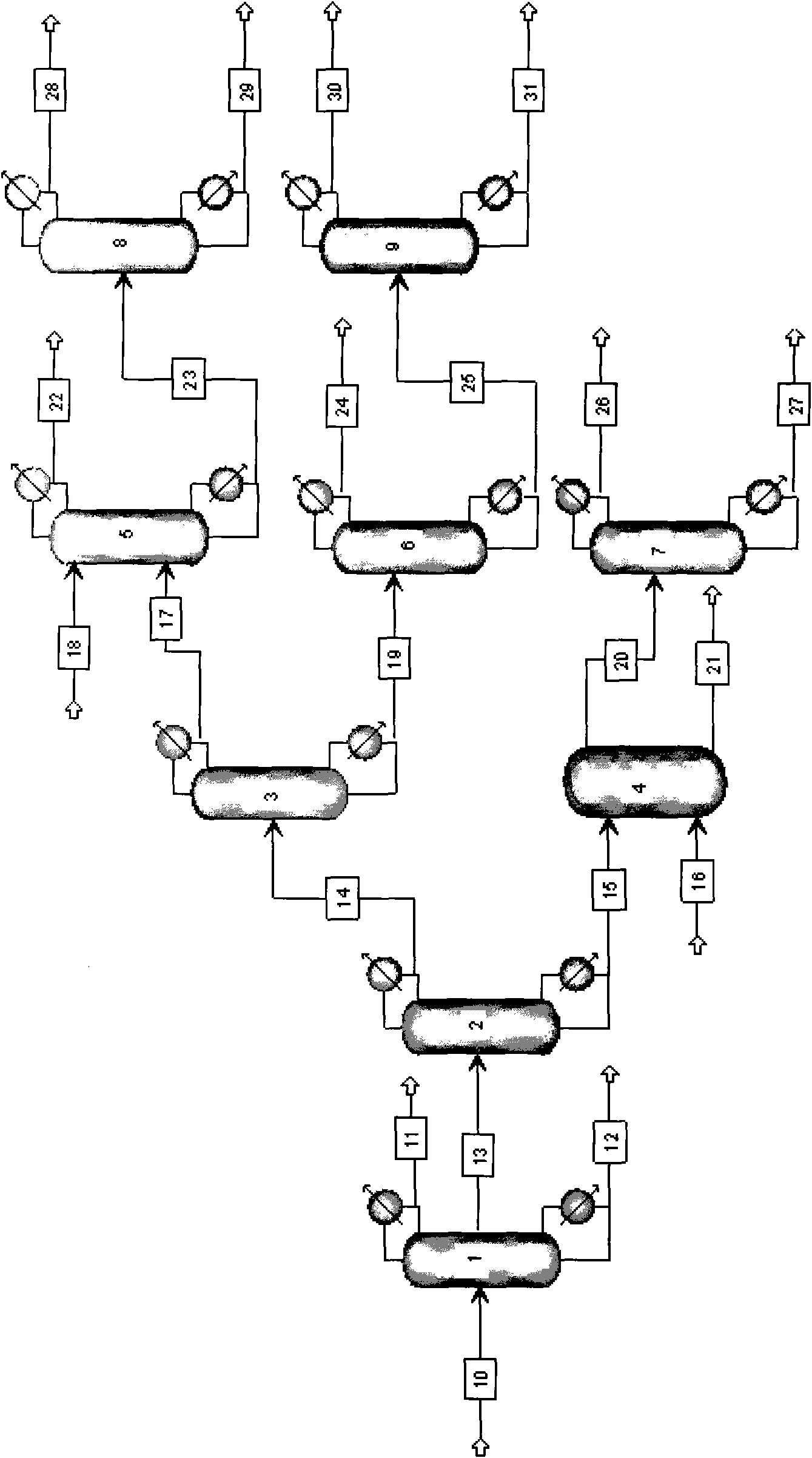

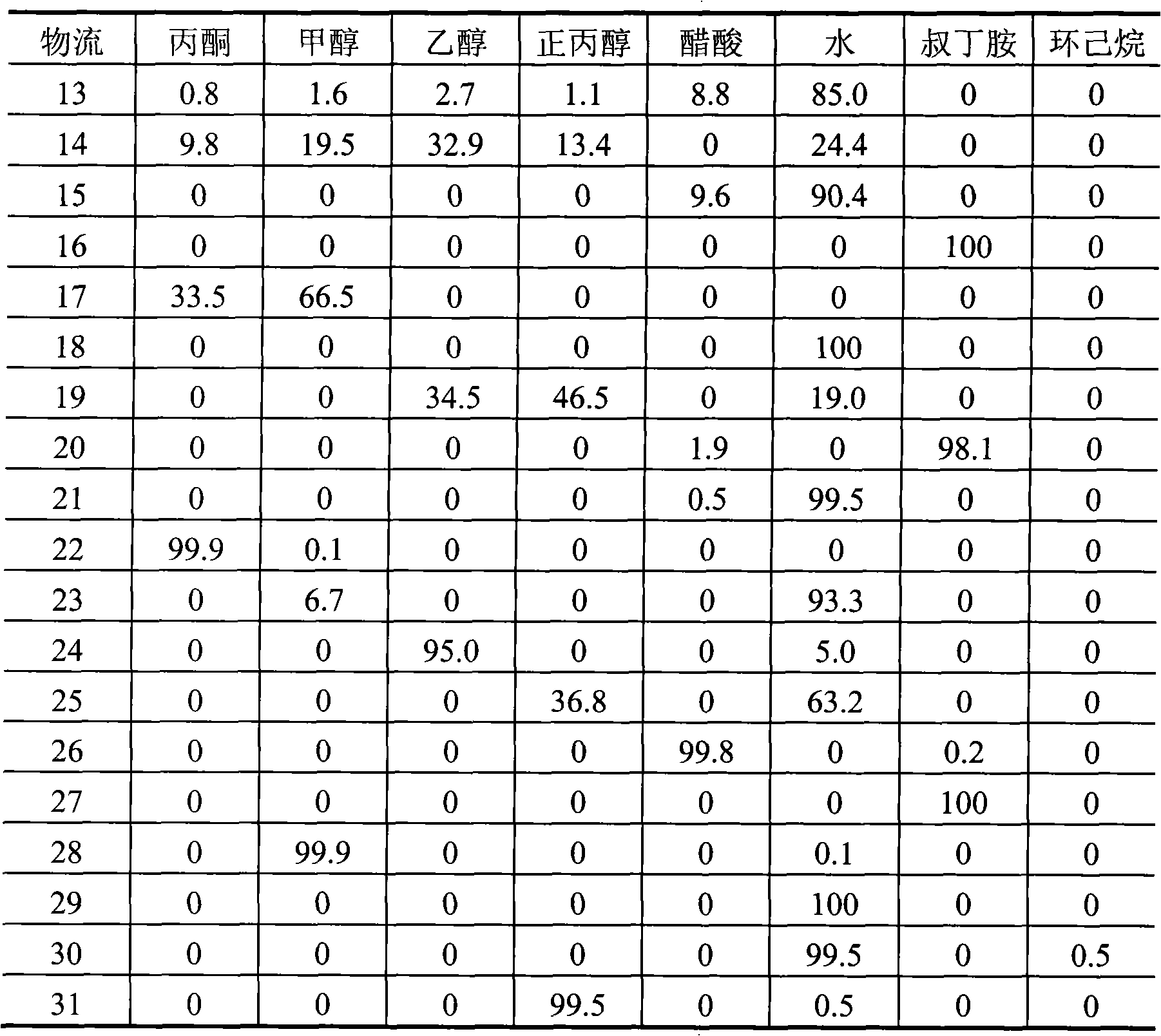

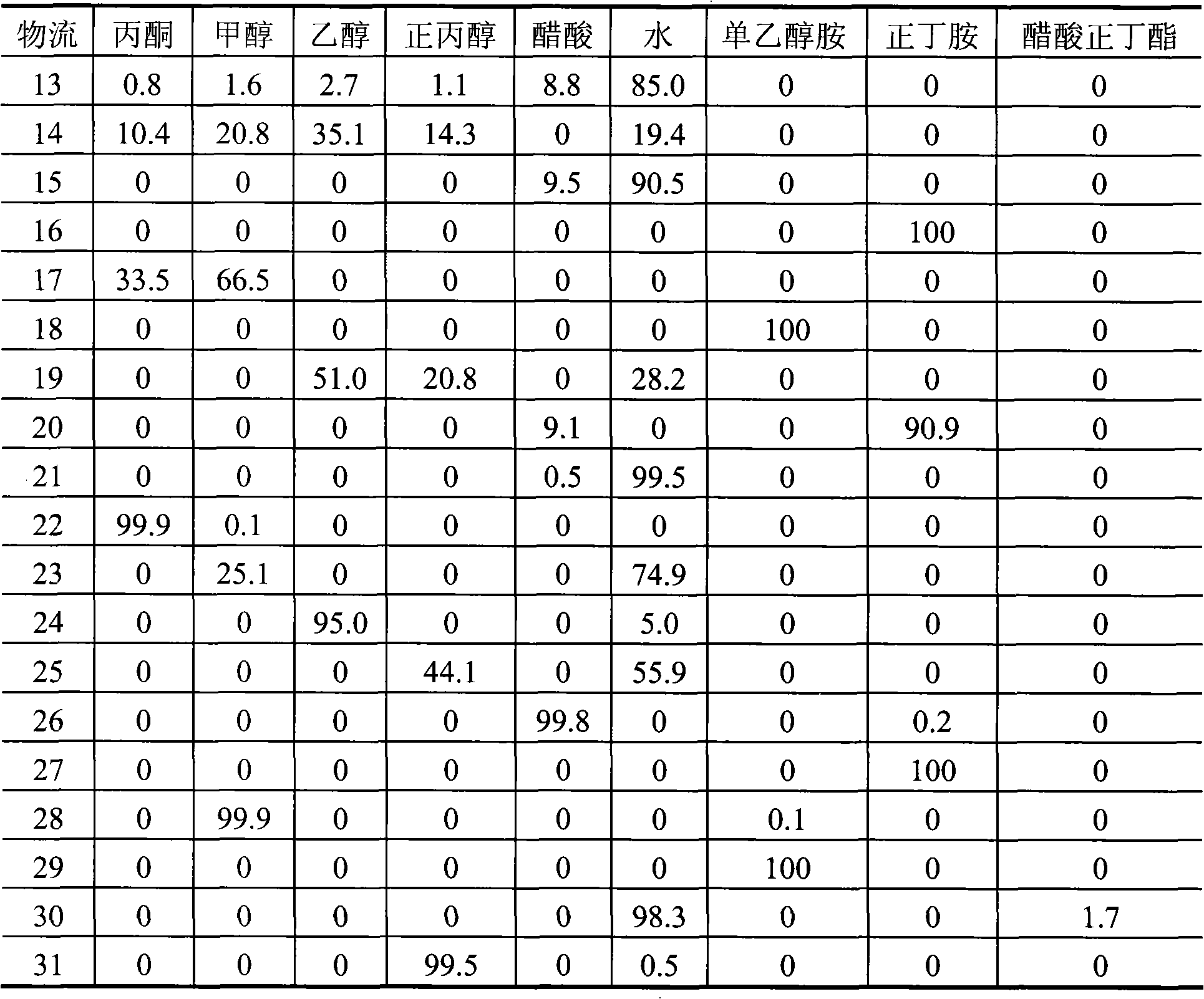

[0015] according to figure 1 The process shown, the Fischer-Tropsch synthesis aqueous phase by-product 10 (components with a boiling point less than 40°C, components with a boiling range of 50 to 120°C and components with a boiling point greater than 120°C account for 5%, 85% of the weight composition respectively and 10%) enter the common rectifying column 1 that the number of theoretical plates is 15, the feeding position is the 7th theoretical plate, the reflux ratio is 12, the control tower top temperature is 40 DEG C, and the side line is taken from the 8th theoretical plate The fraction 13 with a boiling range of 50-120°C is discharged, and the side stream fraction 13 enters the acetic acid cutting tower 2 with a theoretical plate number of 15, the 8th theoretical plate at the feeding position, a reflux ratio of 8, and a control tower kettle temperature of 104- 108°C, the distillate at the top of the tower is alcohol and ketone aqueous solution 14, and the acetic acid aq...

Embodiment 2

[0019] according to figure 1The process shown, the Fischer-Tropsch synthesis aqueous phase by-product 10 (components with a boiling point less than 40°C, components with a boiling range of 50 to 120°C and components with a boiling point greater than 120°C account for 5%, 85% of the weight composition respectively and 10%) enter the common rectifying tower 1 that the number of theoretical plates is 60, the feeding position is the 35th theoretical plate, the reflux ratio is 1, the control tower top temperature is 40 ℃, and the side line is extracted from 40 theoretical plates The fraction 13 with a boiling range of 50-120°C and the side-draw fraction 13 enter the acetic acid cutting tower 2, the number of theoretical plates is 50, the feeding position is the 30th theoretical plate, the reflux ratio is 8, and the temperature of the control tower is 104-108 ℃, the distillate at the top of the tower is alcohol and ketone aqueous solution 14, and the tower kettle obtains acetic acid...

Embodiment 3

[0023] according to figure 1 The process shown, the Fischer-Tropsch synthesis aqueous phase by-product 10 (components with a boiling point less than 40°C, components with a boiling range of 50 to 120°C and components with a boiling point greater than 120°C account for 5%, 85% of the weight composition respectively and 10%) enter the common rectifying column 1 that the number of theoretical plates is 30, the feed position is the 17th theoretical plate, the reflux ratio is 3, the control tower top temperature is 40 ℃, and the side line is extracted from 20 theoretical plates The fraction 13 with a boiling range of 50-120°C and the side stream fraction 13 enter the acetic acid cutting tower 2 with a theoretical plate number of 30, the 17th theoretical plate at the feeding position, a reflux ratio of 4, and a temperature of 104-108 in the control column ℃, the distillate at the top of the tower is alcohol and ketone aqueous solution 14, and the tower kettle obtains acetic acid aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com