Pilot milling cone tool for repairing casing and method thereof

A taper milling and leading technology, which is applied in the field of leading taper milling tools for high-strength cemented carbide grinding and milling materials, can solve problems such as unsolvable casing repair measures and smaller diameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

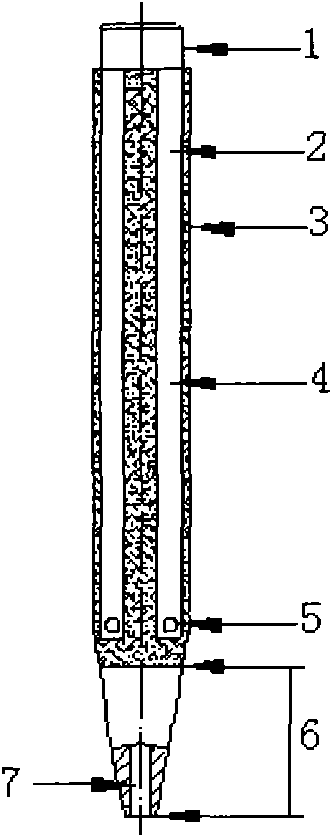

[0056] The present invention adopts the structure of pilot hole milling cone repair casing (see figure 1 ), including the joint 1, the body 2, the milling material 3 on the body, the circulating water channel 4, the circulating water eye 5, the pilot eye 6 and the central hole 7. The pilot hole milling cone is connected to the downhole casing damage through the drill pipe, and the pilot hole part at the front end is introduced into the original wellbore at the lower part of the casing damage. , the pilot hole milling cone continues to grind and expand the damaged casing, and finally drills the channel to meet the needs of the expansion pipe subsidy in the next step or the secondary cementing of the small casing.

[0057] Now specifically illustrate the application of the present invention with embodiment. Figure 4 It is a schematic diagram of the basic well conditions before casing repair after casing damage in a certain well. In the figure, the oil layer casing 11 specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com