Welding track detection and control method of container corrugated plate based on laser ranging

A technology of laser distance measurement and control method, applied in the direction of using feedback control, program control, measuring device, etc., can solve the welding field that is not suitable for high precision and high speed, the application method is difficult to master, and the form of droplet transition of detection accuracy , the impact of spatter and other issues, to achieve friendly human-computer interaction, improve welding quality and welding efficiency, and improve the effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

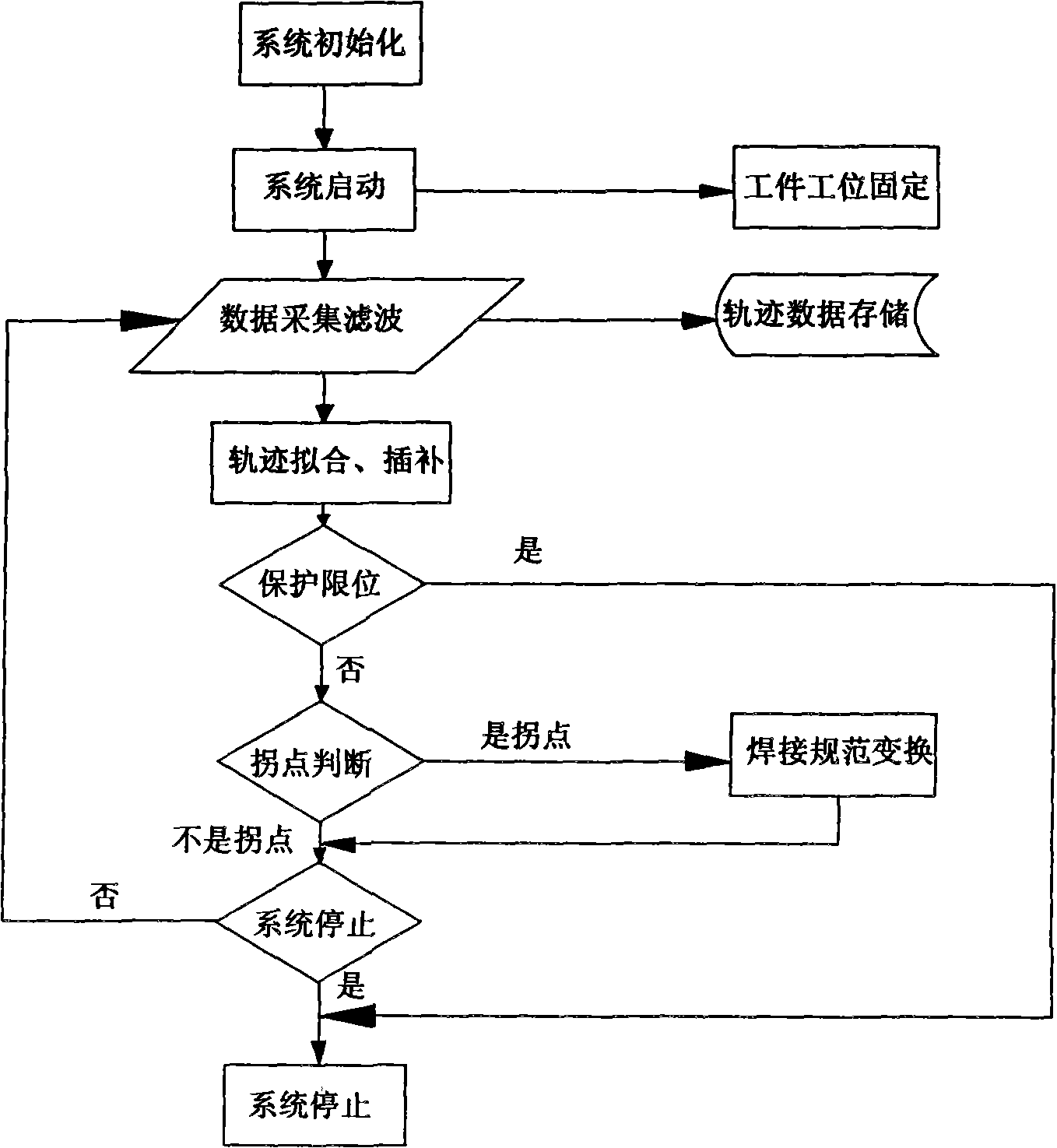

[0030] A method for detecting and controlling the welding trajectory of container corrugated plates based on laser ranging, comprising the following steps:

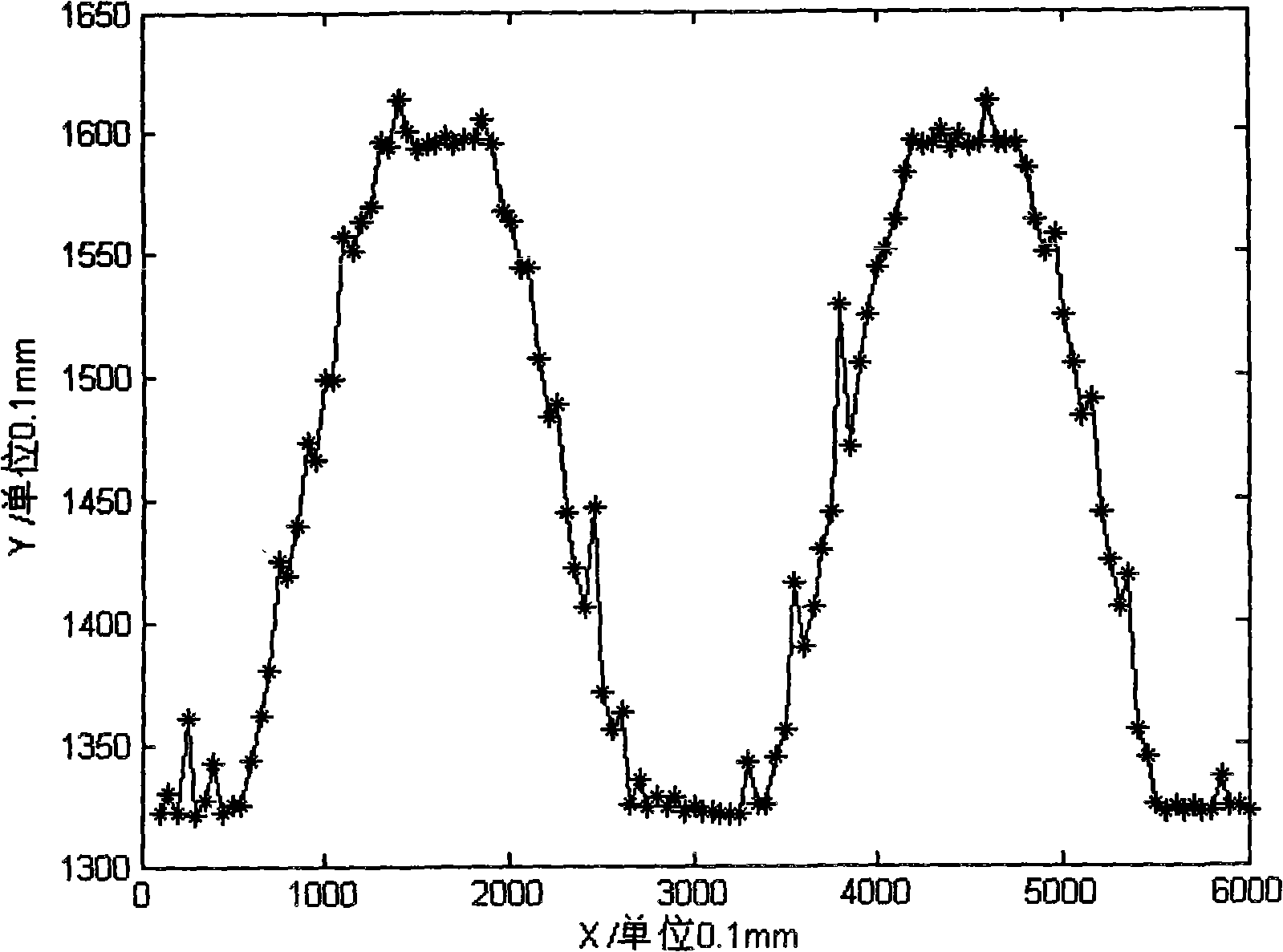

[0031] A. Carry out track detection; after the system is initialized, the horizontal feed is started as the active feed axis, and the corrugated track of the corrugated plate is detected in real time through the laser precision displacement sensor, and the detected initial information data of the weld is sent to the microprocessor. Collect data for filtering and storage;

[0032] B. Carry out track identification; process the digital signal through the microprocessor to extract the information of the weld, and at the same time, the inflection point judgment module is constantly identifying whether the current position is an inflection point, that is, the connection point discrimination between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com