Process method for rewelding of high strength steel

A process method and high-strength steel technology, applied in the direction of manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of difficult preheating work, poor working environment, and low work efficiency, so as to improve the quality and production efficiency of rework welding, shorten Heating time and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

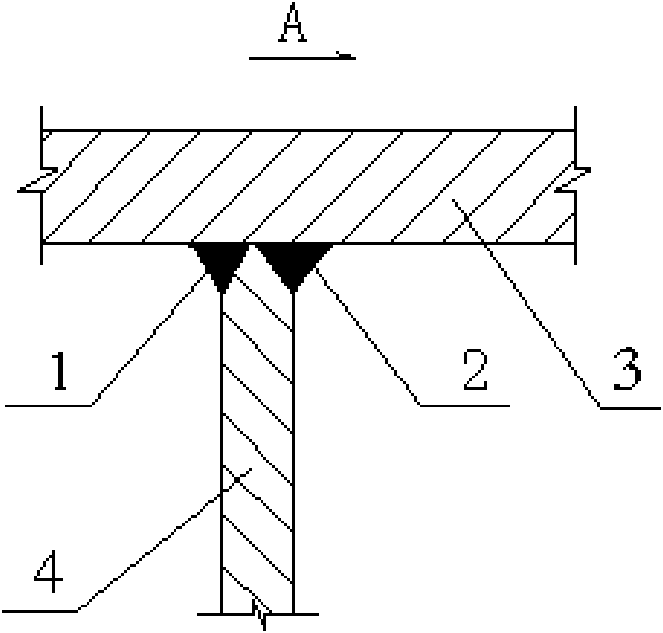

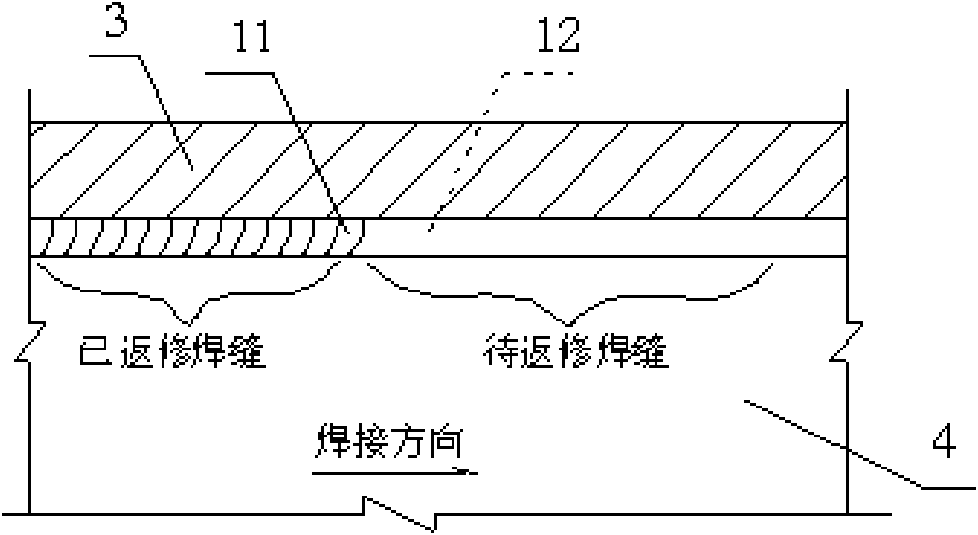

[0018] like figure 1 , figure 2 As shown, the fillet welding between the high-strength steel plate 3 and the high-strength steel plate 4, the specific repair process is:

[0019] Remove all weld defects and extend them to 10-15mm outside the two ends of the crack to form reworked weld grooves 1 and 2 suitable for welding, and use a grinder to grind the reworked weld grooves 1 and 2 and the surrounding areas to reveal metallic luster;

[0020] Sufficiently heat the reworked weld seam suitable for welding within the range of 500mm on each side of groove 1 and 2, and the temperature is 80-90°C;

[0021] Before welding the reworked weld groove 1 that is suitable for welding, the position of the welding spot 11 corresponding to the weld groove 1 on the back of the high-strength steel plate 4, that is, the weld 2, is continuously heated so that the corresponding weld groove 1 is welded. The local preheating temperature of the solder joint before welding is 200±20°C;

[0022] Usi...

specific Embodiment 2

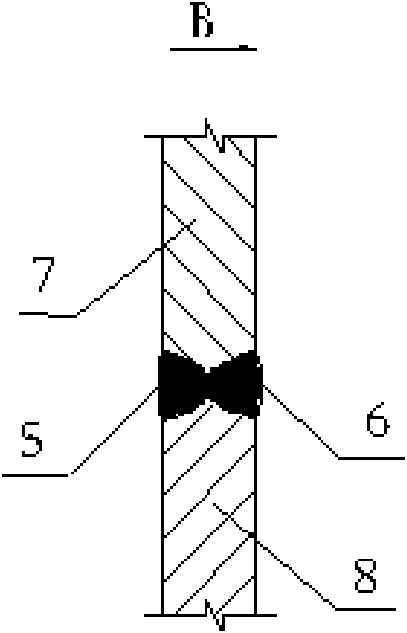

[0025] like image 3 , Figure 4 As shown, the high-strength steel plate 7 and the high-strength steel plate 8 are butt welded, and the specific repair process is:

[0026] Remove all weld defects and extend to 10-15mm outside the two ends of the crack to form reworked weld grooves 5 and 6 suitable for welding, and use a grinder to grind the reworked weld grooves 5 and 6 and the surrounding areas to reveal metallic luster;

[0027] Fully heat the reworked weld grooves within 500mm on each side of grooves 5 and 6 at a temperature of 80-90°C;

[0028] Before welding the reworked weld groove 5 that is suitable for welding, the position of the welding spot 15 on the back of the high-strength steel plate 7 and 8, that is, the weld 6 corresponding to the weld groove 5, is continuously heated, so that the corresponding weld groove 5 The local preheating temperature before welding of the upper welding spot 15 is 200±20°C;

[0029] Using CO 2 Gas shielded welding is used for rework...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com