Method and device for polishing magnetic field auxiliary flexible rotary brush for optical element

A magnetic field-assisted, optical element technology, applied in polishing compositions containing abrasives, optical surface grinders, grinding/polishing equipment, etc., can solve the problem that the quality of the machined surface and the stability of the removal function and the computer control ability are not high. Accurate optical processing, inability to meet the needs of conformal optical inner concave processing, etc., to achieve the effect of compact structure and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

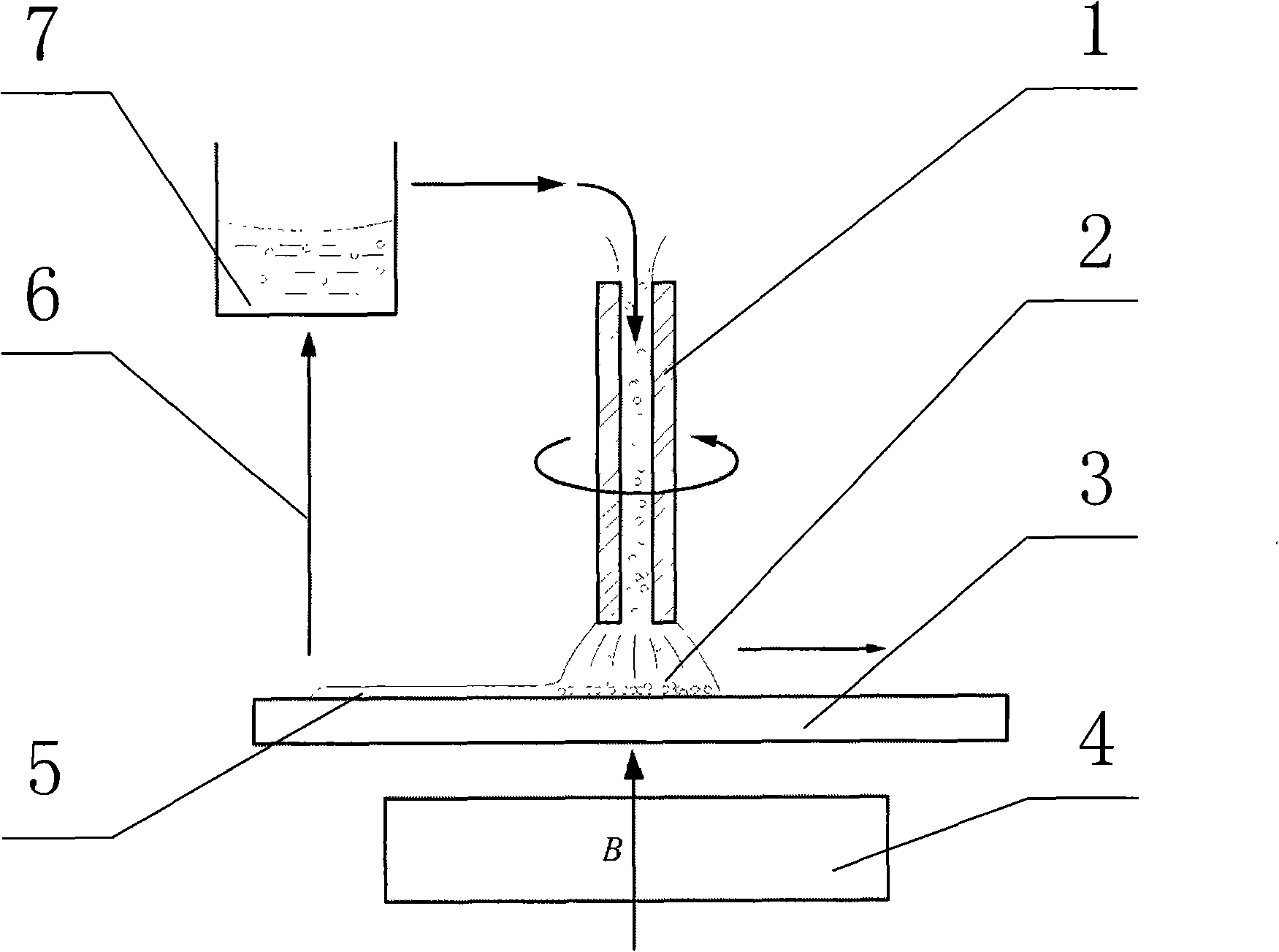

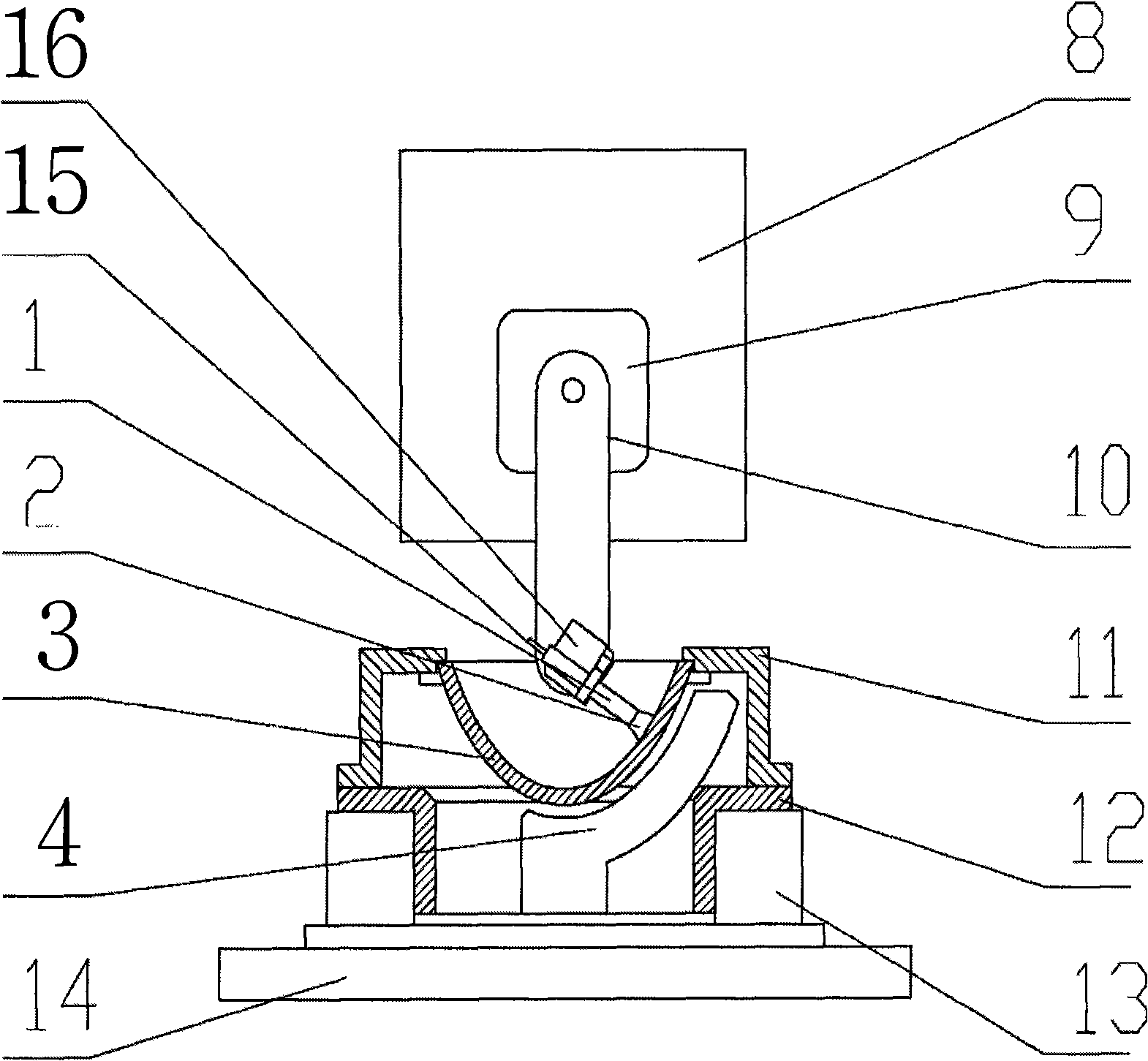

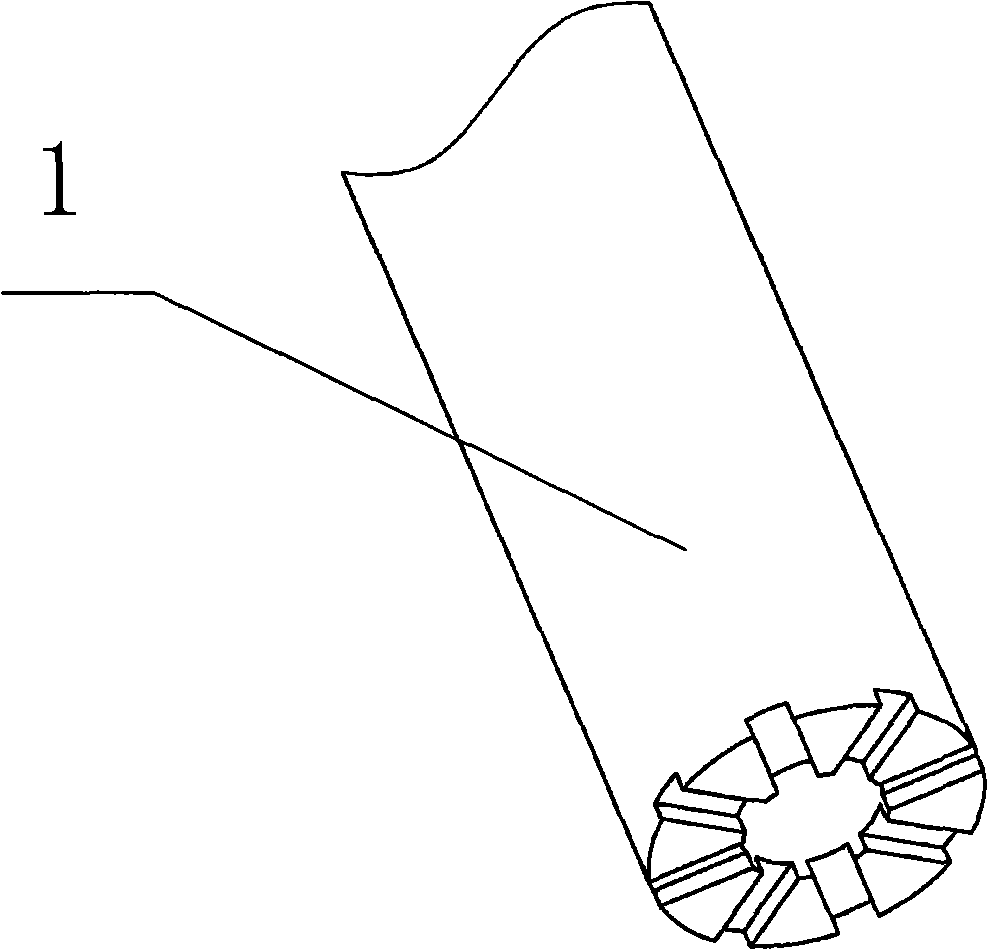

[0032] figure 2 It is a schematic diagram of the structure of the device for polishing the inner concave surface of the optical element of the present invention. The polishing turntable base 13 is fixedly connected with the CNC XY workbench 14, the polishing turntable 12 is installed on the polishing turntable base 13, and has a center hole; the excitation pole 4 in the form of a permanent magnet passes through the center hole of the turntable and is fixedly connected with the CNC XY workbench 14 , the workpiece 3 is installed upside down and fixed on the workpiece fixture 11, the workpiece fixture 11 is fixedly connected with the polishing turntable 12, and keeps the symmetry axis of the workpiece 3 and the center of rotation of the polishing turntable 12 coincident; the polishing spindle 1 is made of carbon steel material, with a diameter of 5mm, and driven by the spindle driver 16; the spindle driver 16 is a micro DC motor, using gear transmission; the polishing spindle 1 ...

Embodiment 2

[0040] In this embodiment, the excitation pole 4 is in the form of an electromagnet, and the magnetic field intensity in the processing area can be further controlled by current. The device structure and processing method of other parts are the same as in Embodiment 1.

Embodiment 3

[0042] In this embodiment, the main shaft driver 16 is driven by a flexible shaft, and the flexible shaft is driven by an external motor to obtain higher rotational speed and driving torque. The device structure and processing method of other parts are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com