Method for processing 3, 4-dichloroaniline in water

A technology for dichloroaniline and water treatment, applied in chemical instruments and methods, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as low energy efficiency, high energy consumption, and restricted application range, and achieve The reactor equipment and operation are simple, energy consumption is reduced, and the effect of energy saving is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

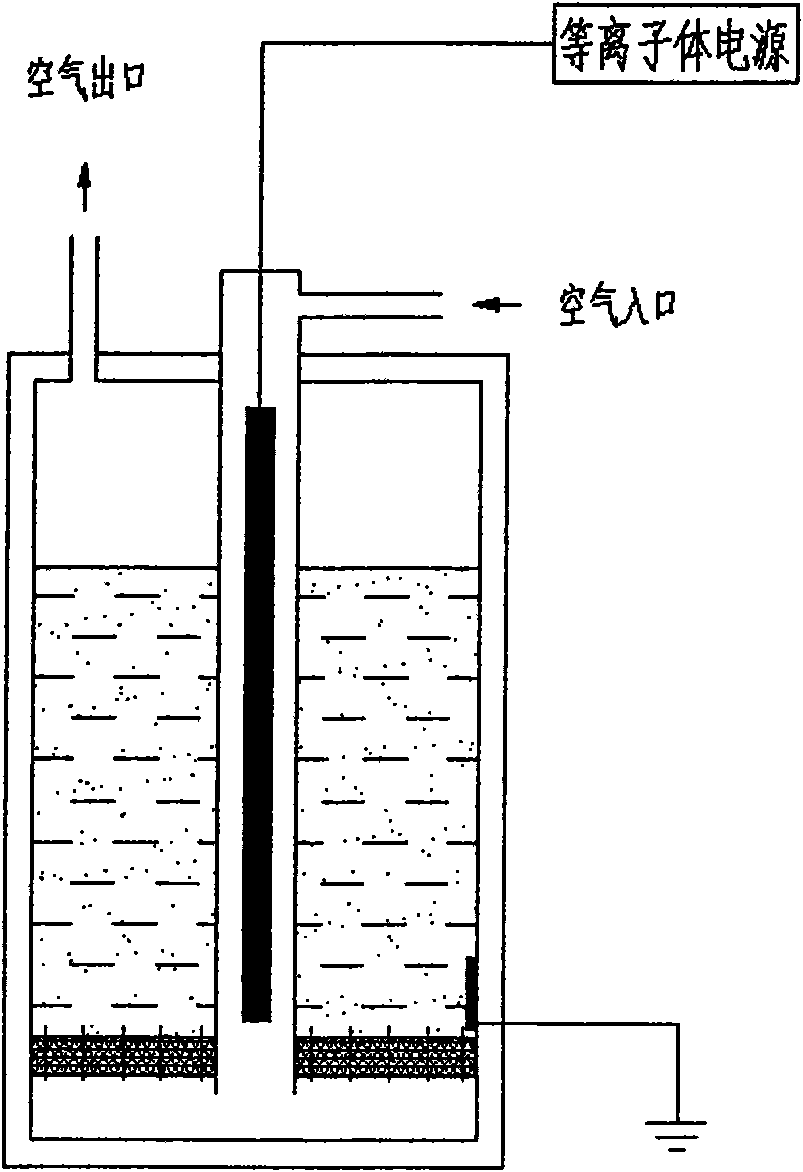

Method used

Image

Examples

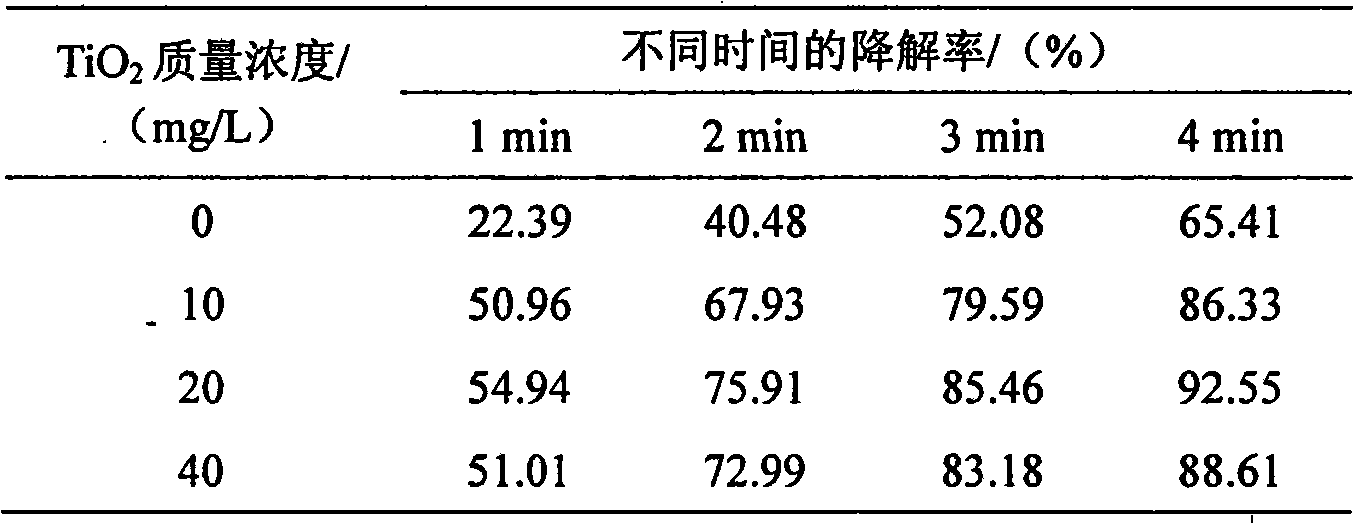

Embodiment 1

[0021] Put 150mL of 3,4-dichloroaniline water with a concentration of 30mg / L into the above-mentioned dielectric barrier discharge reactor containing photocatalyst titanium dioxide, mix well, and control the amount of titanium dioxide photocatalyst to 0mg / L and 10mg / L respectively , 20mg / L, 40mg / L. Adjust the air flow valve to control the aeration air intake to 1L / min, adjust the input excitation voltage and frequency of the voltage regulator so that the peak value of the discharge voltage is about 10kV, the peak value of the discharge current is 80mA, the discharge power is 80W, and the degradation treatment takes 4 minutes. Table 1 shows the treatment effect of different titanium dioxide photocatalyst mass concentrations on 3,4-dichloroaniline wastewater. It can be seen from Table 1 that in the presence of photocatalyst, the removal rate of 3,4-dichloroaniline is significantly improved, and it first increases and then decreases with the increase of the amount of photocatalys...

Embodiment 2

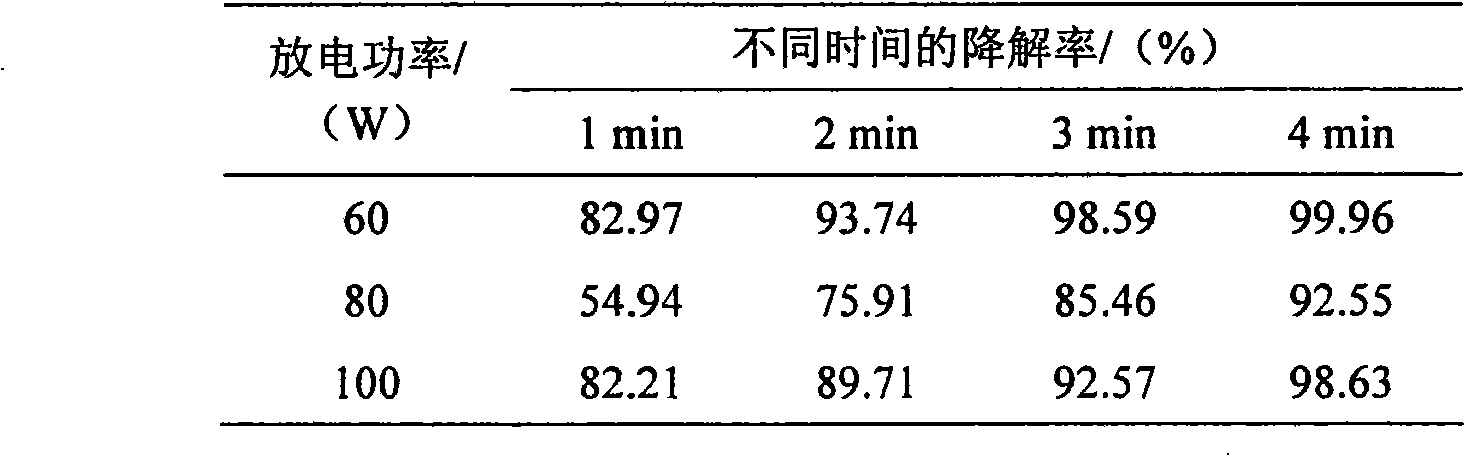

[0025] Same as Example 1, only the mass concentration of the photocatalyst titanium dioxide in Example 1 is controlled to be 20mg / L, and the discharge power is controlled to be 60W, 80W, and 100W respectively. Table 2 shows the treatment effect of different discharge powers on 3,4-dichloroaniline wastewater under the mass concentration of titanium dioxide photocatalyst 20mg / L. It can be seen from Table 2 that in the presence of a photocatalyst, a lower discharge power of 60W can achieve a higher removal rate of 3,4-dichloroaniline.

[0026] Table 2 The same photocatalyst TiO 2 Degradation rate of 3,4-dichloroaniline under different discharge powers

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com