Method for manufacturing ferrosilicon by silica fume, coke powder and oxidized sheet iron pressed compact

A technology of iron oxide scale and ferrosilicon alloy, applied in the field of ferroalloy production, can solve the problems affecting the working and living environment of the production plant and surrounding residents, rising production costs, declining economic benefits, etc., so as to improve the working environment of workers, save electricity, and save smelting cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

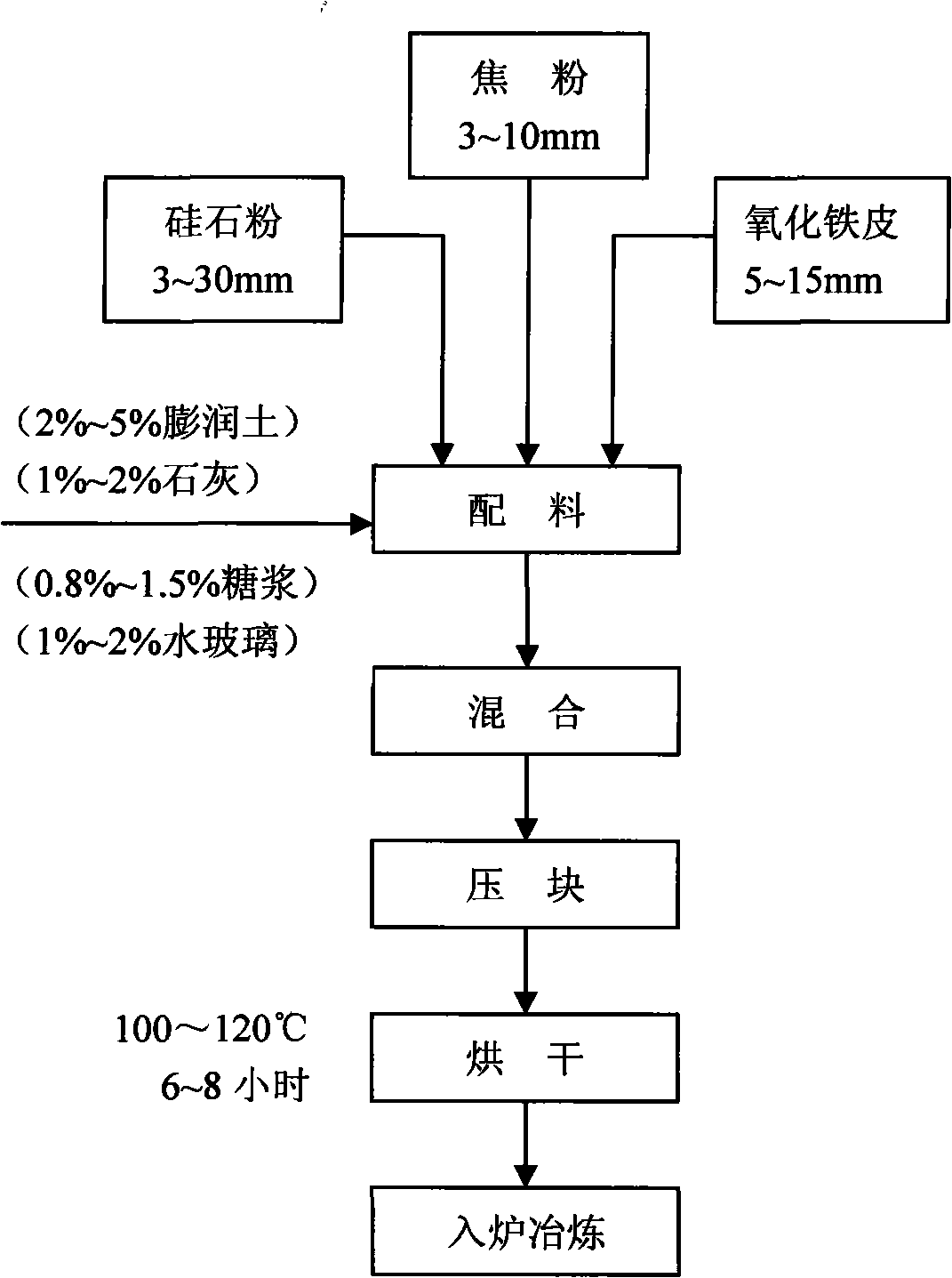

Method used

Image

Examples

Embodiment 1

[0021] According to the composition requirements of producing 75 ferrosilicon alloy, take SiO 2 98% waste silica powder: 58%, coke powder with 85% carbon content: 28%, iron oxide scale: 8%, bentonite: 2%, industrial syrup: 1.0%, water glass: 1.5%, lime: 1.5% %. Among them, the particle size of silica powder is less than 28mm, the particle size of coke powder is less than 10mm, and the particle size of iron oxide scale is less than 15mm;

[0022] The preparation method is:

[0023] Use waste silica powder, coke powder and iron oxide scale as the main raw materials;

[0024] Mix the bentonite, lime, industrial syrup, water glass and appropriate amount of water in the formulated amount, and use it as a binder to mix with the above-mentioned main raw materials, stir evenly, and then press into a briquette that meets the furnace standard, at 120°C Drying for 6 hours, and finally into the furnace for smelting, you can get the 75 ferrosilicon alloy that meets the requirements.

Embodiment 2

[0026] The difference between this embodiment and embodiment 1 is that the formula and drying conditions are adjusted, and the rest are the same as embodiment 1.

[0027] According to the composition requirements of producing 75 ferrosilicon alloy, take SiO 2 97% waste silica powder: 60%, coke powder with 90% carbon content: 25%, iron oxide scale: 7%, bentonite: 4%, industrial syrup: 1%, water glass: 1%, lime: 2% .

[0028] The drying condition is 100° C. for 8 hours. The 75 ferrosilicon alloy that meets the requirements can be obtained.

Embodiment 3

[0030] The difference between this embodiment and embodiment 1 is that the formula and drying conditions are adjusted, and the rest are the same as embodiment 1.

[0031] According to the composition requirements of producing 75 ferrosilicon alloy, take SiO 2 99% waste silica powder: 55%, coke powder with 84% carbon content: 32%, iron oxide scale: 7%, bentonite: 3%, industrial syrup: 1%, water glass: 1%, lime: 1% .

[0032] The drying condition is 110° C. for 7 hours. The 75 ferrosilicon alloy that meets the requirements can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com