Shear wall truss hybrid type lateral resisting structure system

A shear wall and hybrid technology, which is applied to building components, building structures, and earthquake resistance, can solve the problems of reducing coupling beams, reducing the internal force of coupling beams, and reducing the reinforcement of coupling beams, so as to reduce shear force and bending moment. , Improve the seismic performance and reduce the effect of coupling beam reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

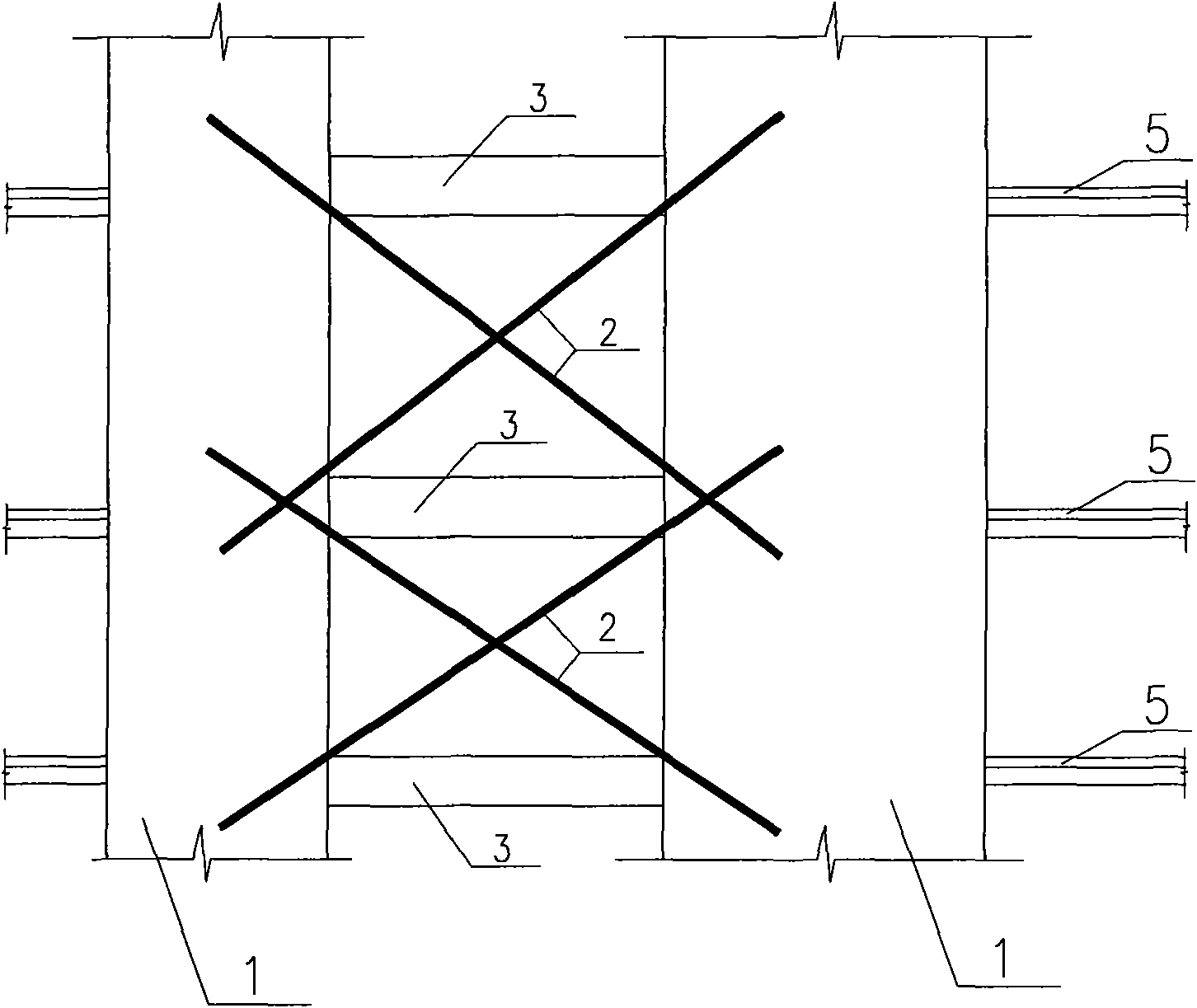

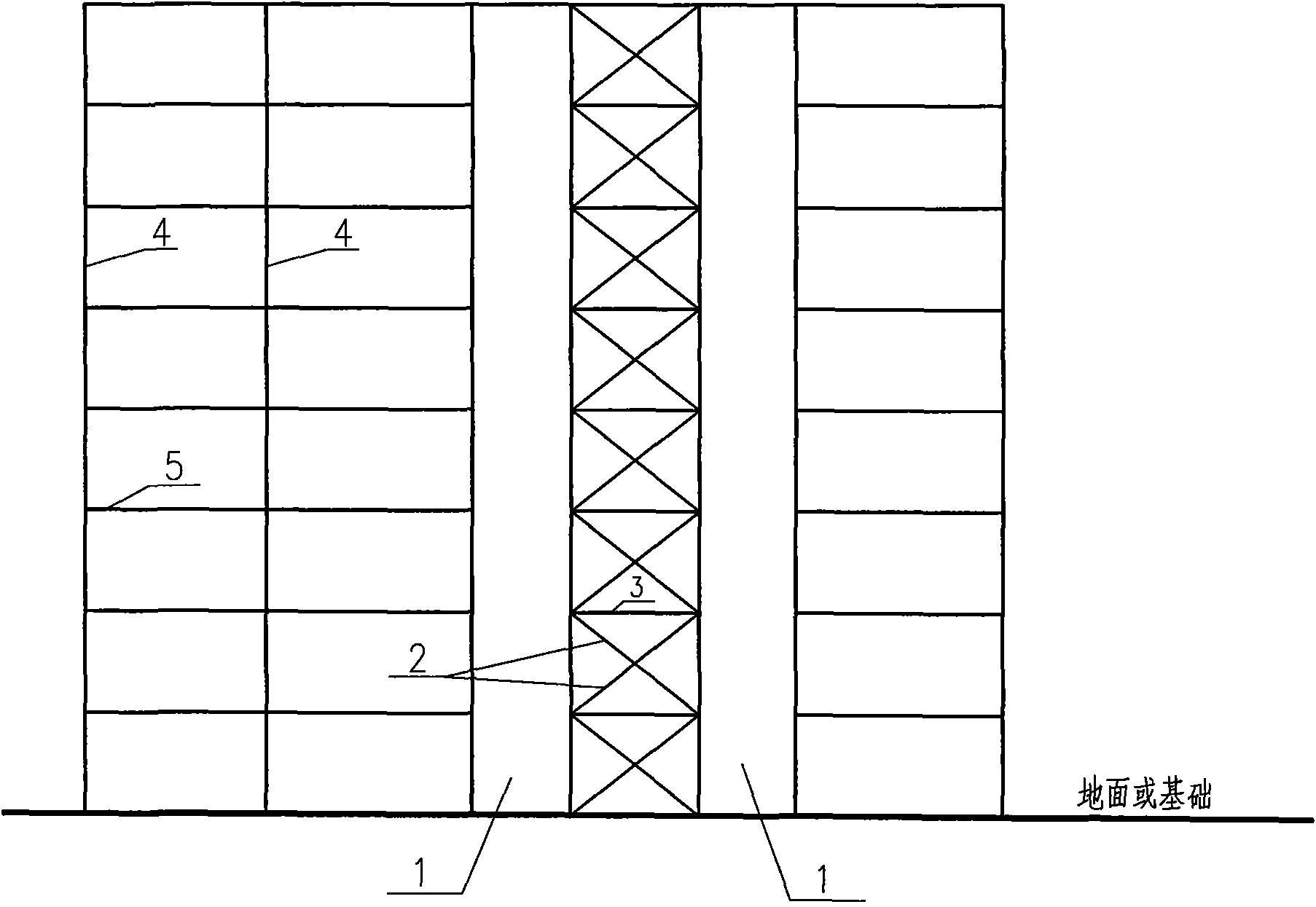

[0026] like figure 1 , figure 2 As shown, the present invention is applied to a frame-shear wall structure, and the frame is composed of a column 4 and a floor 5; an oblique connecting rod 2 is set between two shear walls 1, and the connecting rod 2 passes through the upper and lower floor 5 At the junction of connecting beam 3 and shear wall 1, both ends are fixed on shear wall 1, and connecting rod 2 can be made of high-strength steel strand, section steel or high-strength steel bar. Wall 1 forms a shear wall-truss hybrid structure system to resist horizontal loads.

[0027] By changing the reinforcement and structural form of the coupling beam 3, the coupling beam 3 can be hinged with the shear wall 1. The conventional connection between the shear wall 1 and the coupling beam 3 is a rigid connection. If only the middle part of the connecting beam is provided with steel bars or section steel to connect with the shear wall, it is a hinge, and the hinged connecting beam ba...

Embodiment 2

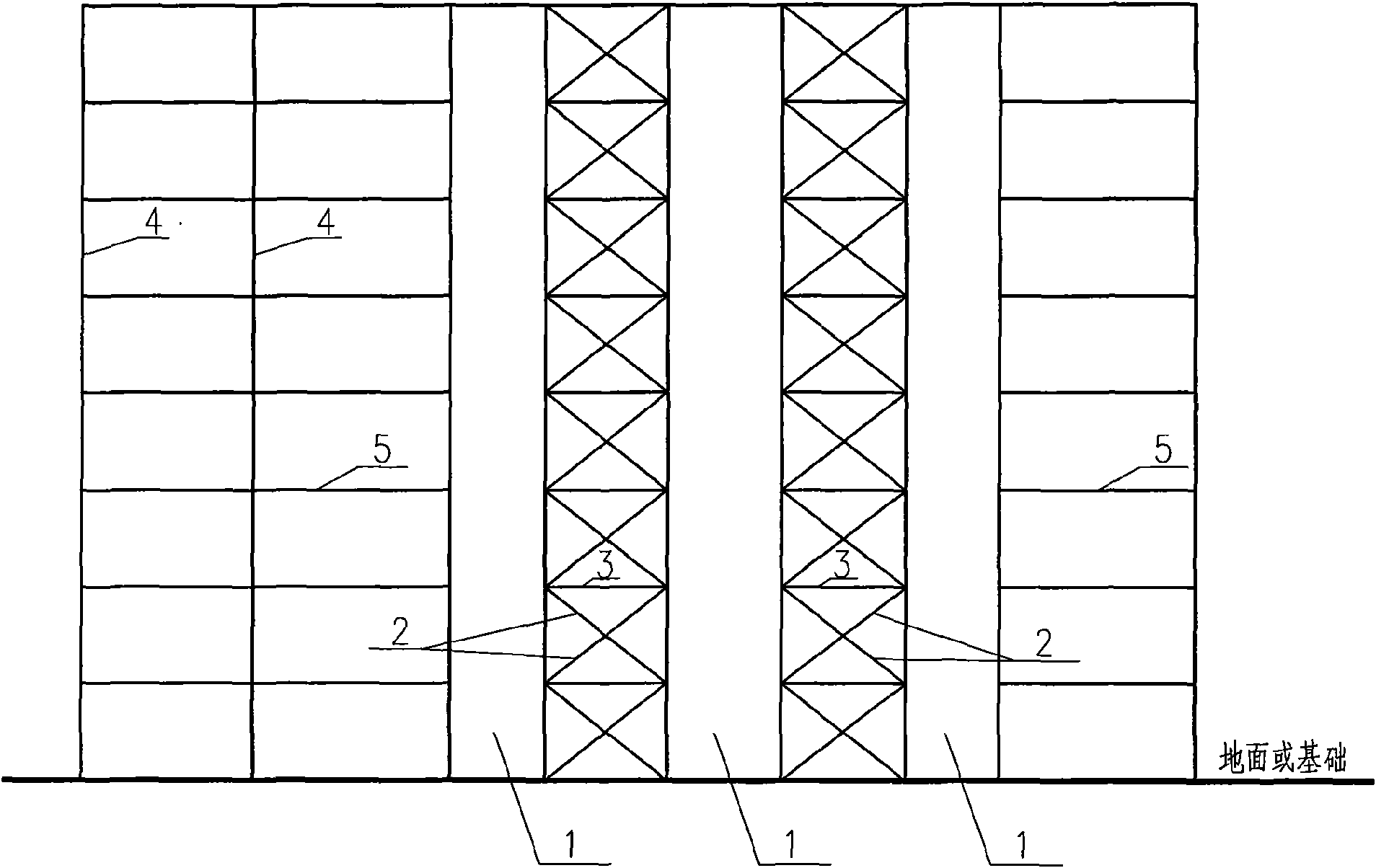

[0029] like image 3 As shown, the shear wall composed of more than three shear walls connected with the corresponding connecting beams is the multi-leg shear wall structure. The present invention is applied to a multi-leg shear wall structure, and oblique connecting rods 2 are respectively arranged between two shear walls 1, and the connecting rods 2, connecting beams 3, and two shear walls 1 form a shear wall-truss hybrid structure system, resistant to horizontal loads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com