Large-flow quick throttle proportional valve

A technology of proportional valve and large flow, which is applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., and can solve the problem of servo valve cost, high use and maintenance costs, short action time, and proportional valves that are difficult to meet the flow and flow requirements at the same time. Action time and other issues, to achieve important application and economic value, reduce the effect of application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

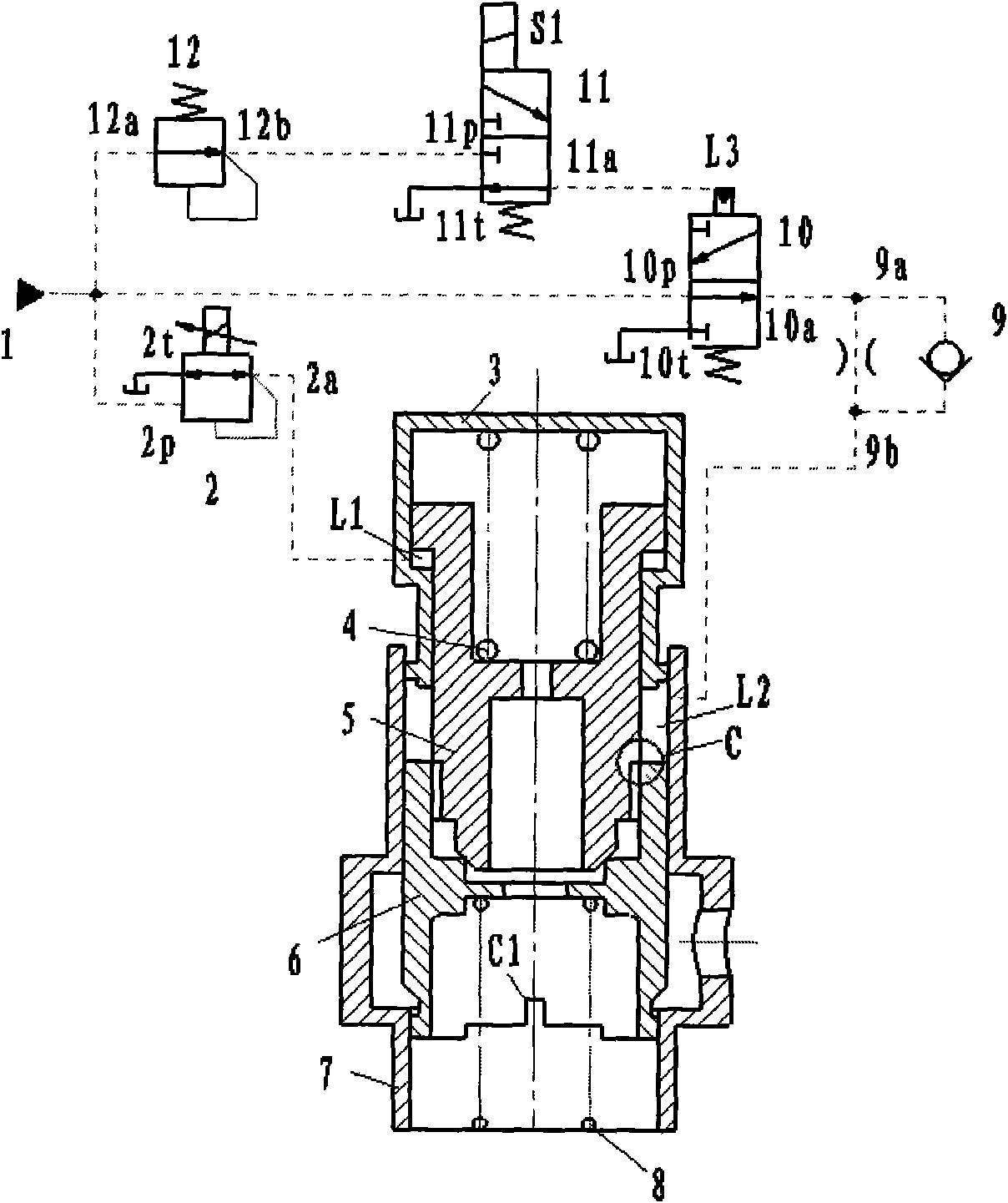

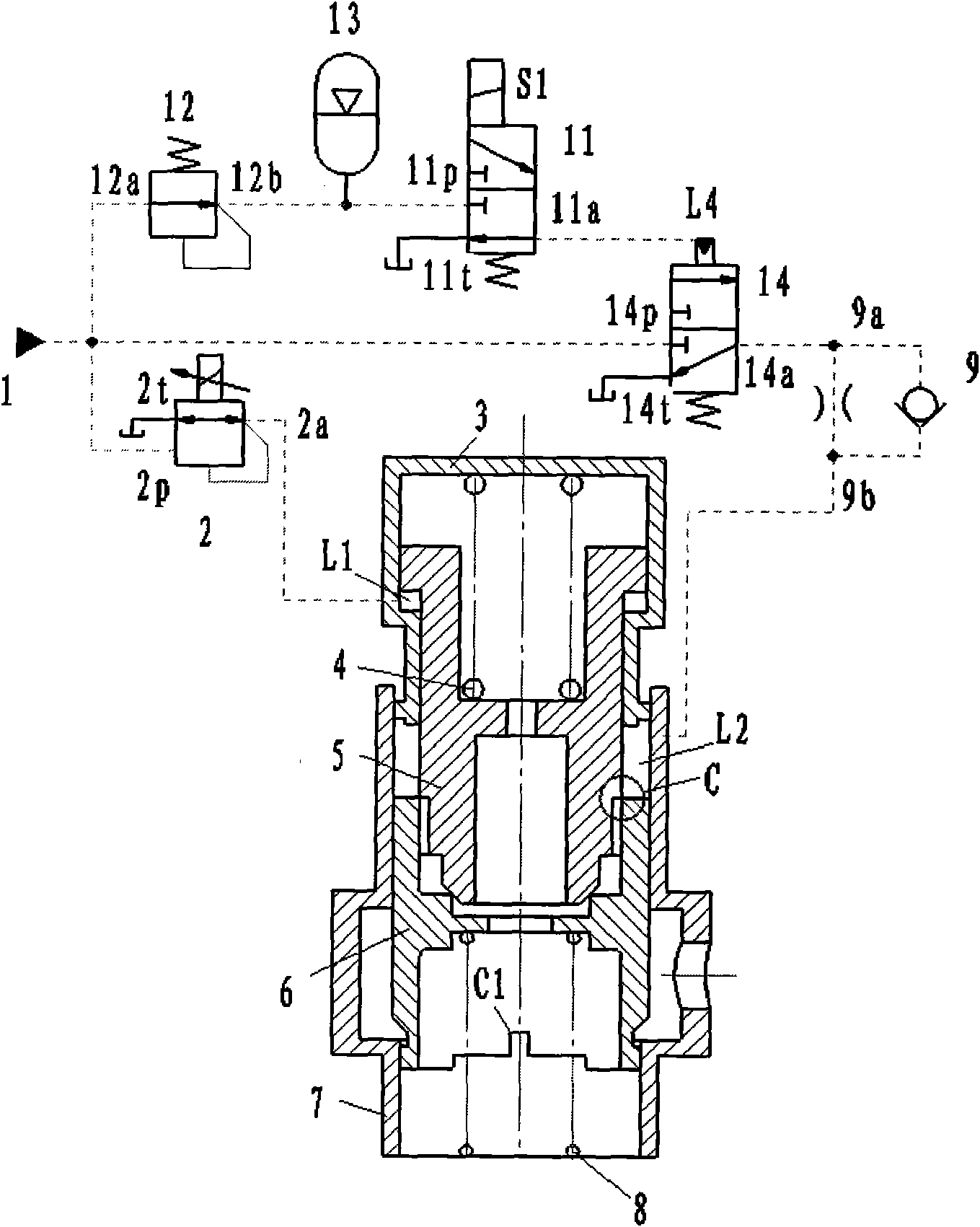

[0017] Such as figure 1 As shown, a large flow rate fast throttle proportional valve, including main stage cartridge valve components and pilot control valve block components, where:

[0018] The main stage cartridge valve components include the main valve core 6, the main valve seat 7 and the return spring 8; , the upper end of the main valve core 6 cooperates with the lower end of the proportional valve stem 5 in the pilot control valve block, and the lower end surface of the main valve core 6 has a throttling window C1;

[0019] Pilot control valve block components include three-way proportional pressure reducing valve 2, piston cylinder 3, adjustment spring 4, proportional valve stem 5, one-way damping valve 9, normally open two-position three-way valve reversing valve 10, pilot high-speed switching valve 11 and two-way pressure reducing valve 12;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com