Micro-fluidic chip with an integrated PDMS surface tension minipump and application thereof

A microfluidic chip and surface tension technology, applied in instruments, biological testing, analytical materials, etc., can solve the problems of high cost, cumbersome production methods, and restricted applications, so as to improve the ability to store waste liquid and increase the maximum sample injection volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

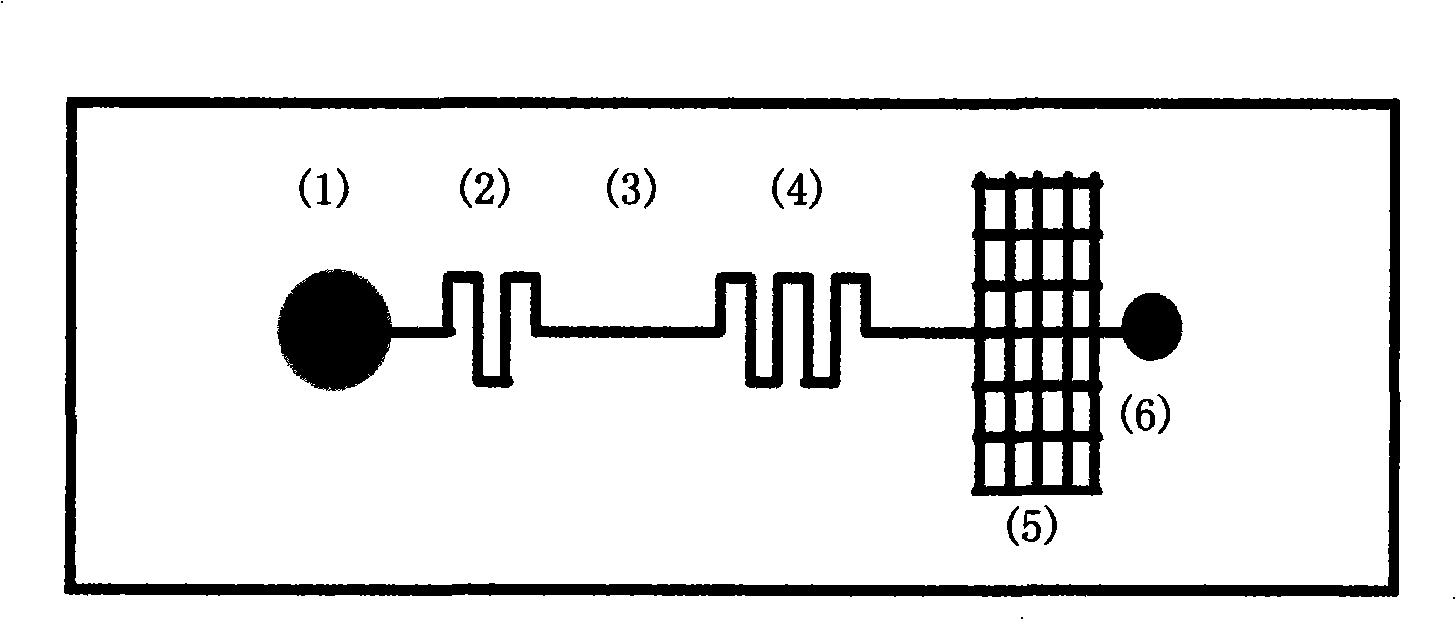

[0023] The microfluidic chip surface tension micropump made based on PDMS realizes the adjustment of different flow rates. chip such as Figure 4 As shown in the middle *, PDMS is used to cover the outlet of the waste liquid pool of the micropump to control the number of waste liquid pools, so that the linear adjustment of the flow rate can be realized within the flow rate scale of nL / s.

[0024] When the number of outlets of the waste liquid pool is zero, the solution stops flowing in the channel at this time, and the flow rate is zero.

Embodiment 2

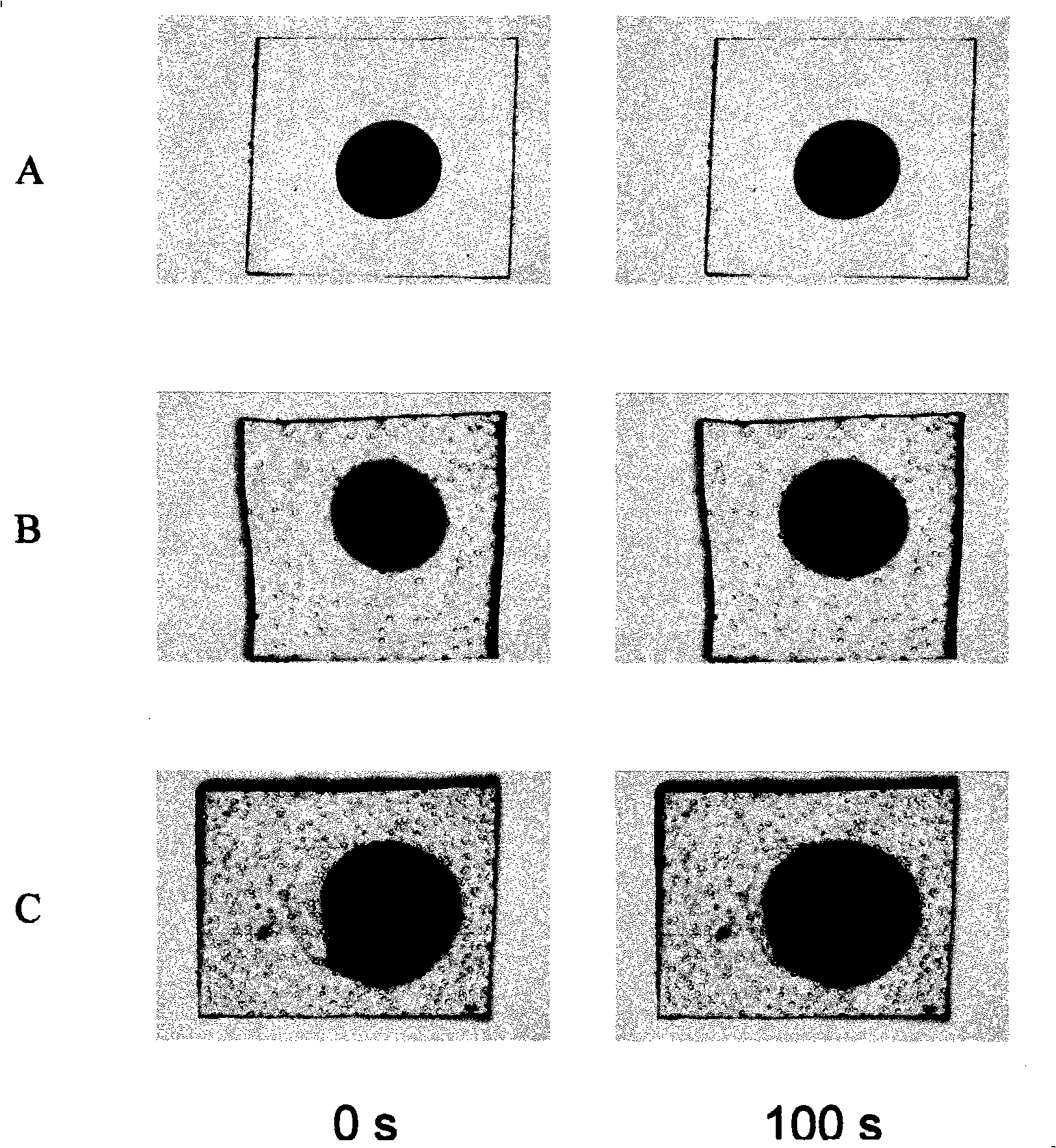

[0026] Microfluidic chip surface tension micropump immunoassay system based on PDMS. The whole immunoassay process requires antibody solution, bovine serum albumin solution, washing solution, sample solution and labeled antibody solution. Use a pipette gun to add these solutions into the sample solution pool in sequence according to the order of the immune reaction. These solutions will flow through the reaction channel in sequence under the action of surface tension, and each step of the immune reaction can be automatically completed, such as coating, sealing, etc. , reaction, washing, etc.

[0027] The whole immunoassay process (using human IgG as a model analyte) is described as follows:

[0028] 1. Use a pipette gun to add the goat anti-human IgG solution into the sample liquid pool. Under the action of surface tension, it will gradually flow into the reaction channel. Since the material used in the reaction channel is unmodified PDMS, which is hydrophobic, the antibody ...

Embodiment 3

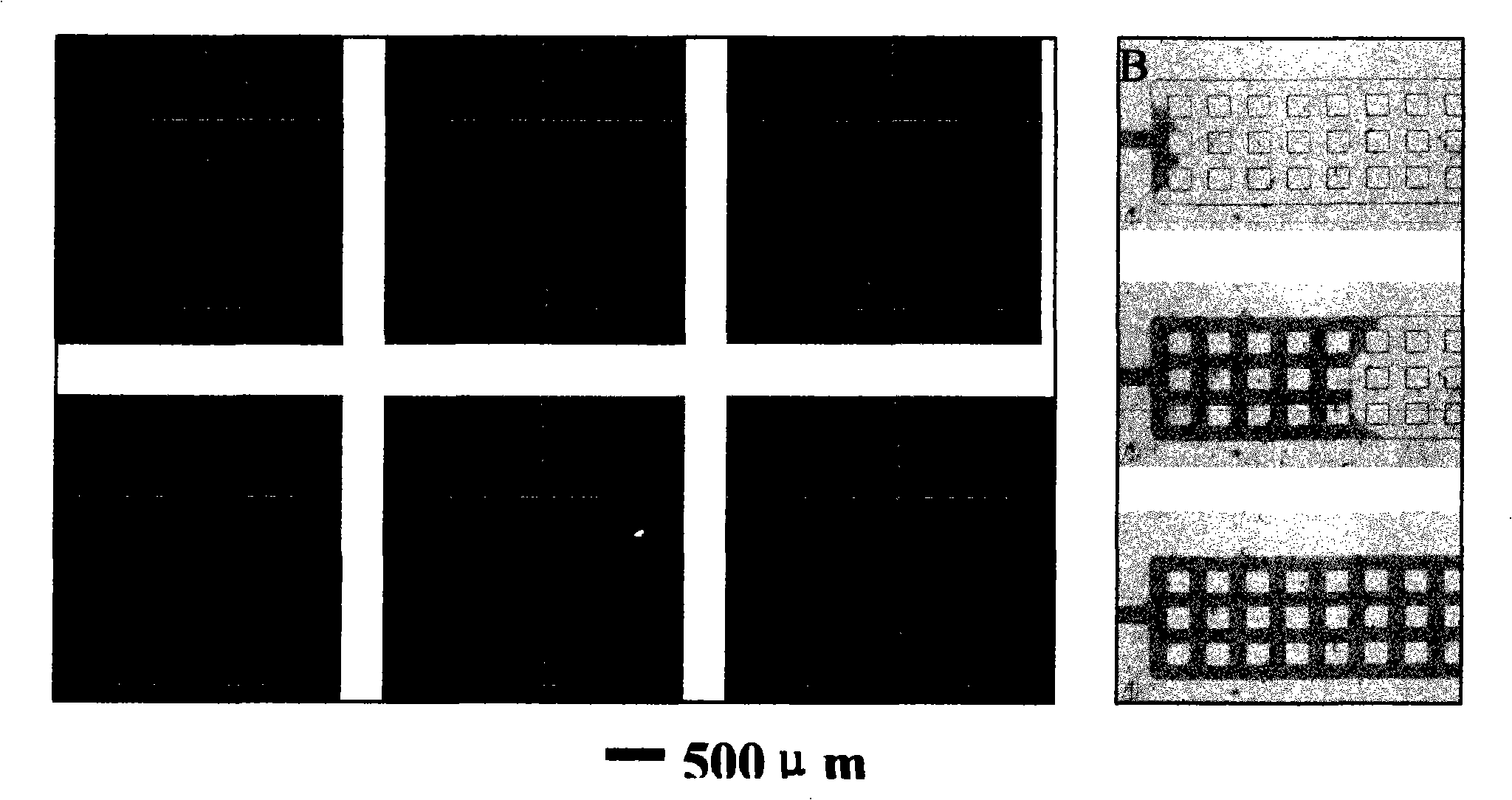

[0039] The microfluidic chip surface tension micropump multi-index immunoassay system based on PDMS, the results are as follows Image 6 shown. Both the upper and lower layers of the chip are PDMS. The upper layer of PDMS is a surface tension micropump, which provides fluid transport power, and the lower layer of PDMS is unmodified, providing a carrier for immune response. The lower layer of PDMS is pre-coated with different antibody bands, and the mixture of samples and various detection antibodies is sequentially added to the sample liquid pool to realize simultaneous analysis and detection of multiple indicators of a sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com