Working table of manual wood planing machine

A technology of workbench and wood planer, which is applied in the direction of manual planer, wood processing equipment, manufacturing tools, etc. It can solve the problems that the surface flatness is not easy to meet the requirements, affect the qualification rate of the workpiece to be processed, and the stability of the workbench, etc., to achieve No internal stress, high hardness, little effect of humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Regarding the technology, means and effects used in the present invention, a preferred embodiment is given and described in detail below with drawings, which are for illustration purposes only, and are not limited by this structure in the patent application.

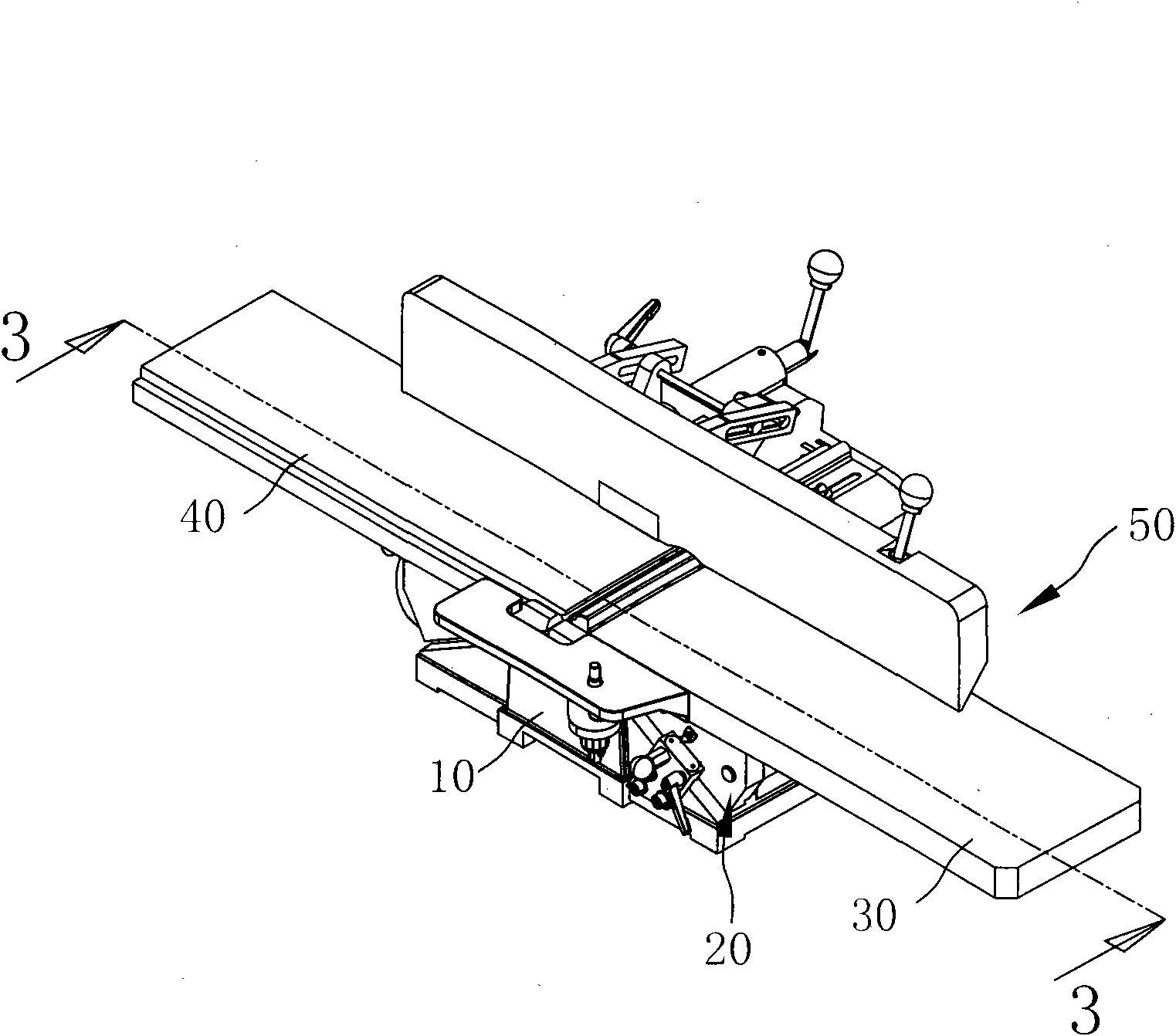

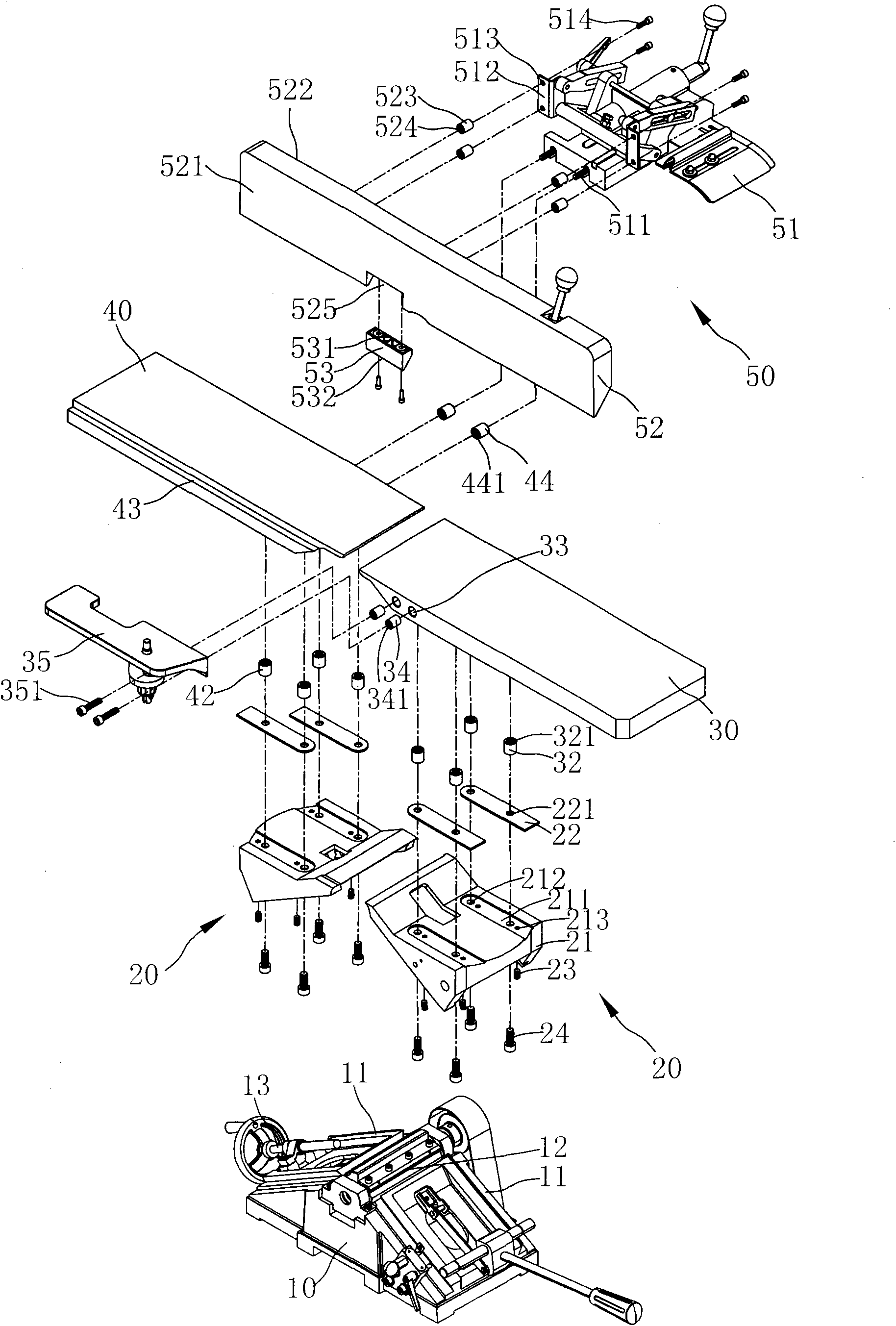

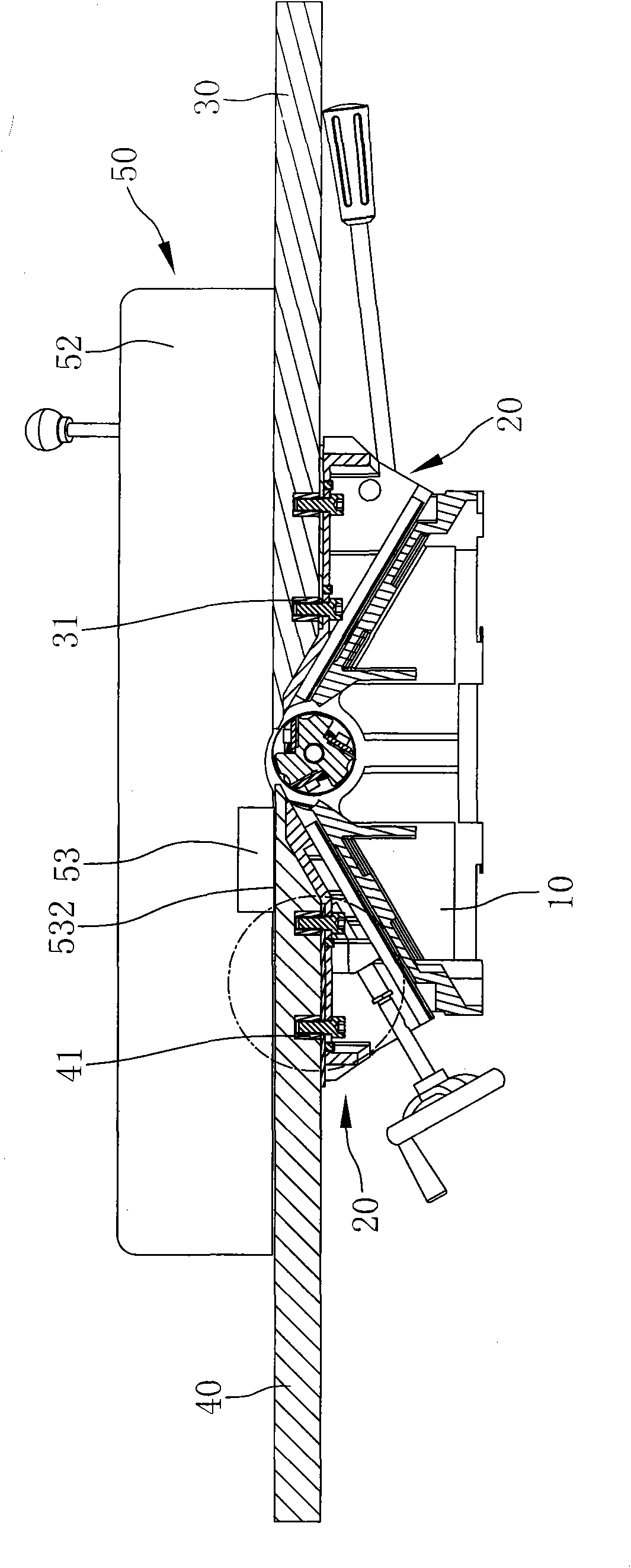

[0020] refer to figure 1 and figure 2 , is the three-dimensional appearance diagram and three-dimensional exploded view of the workbench of the manual planer of the present invention. The workbench of the manual planer of the present invention includes a base 10 , two fine-tuning devices 20 , two granite platforms 30 , 40 and a baffle device 50 .

[0021] The base 10 includes two slopes 11, and a blade set 12 is installed between the two slopes 11 to provide the wood planing function of the wood planer. One of the slopes 11 is provided with a lifting adjustment group 13, and the fine-tuning device 20 is respectively installed on the two slopes 11. The lifting adjustment group 13 can adjust the height of the fir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap