Shrinkproof crease-resistant pretreatment technique of flax fabric

A linen fabric and post-processing technology is applied in the processing of textile materials, continuous processing of textile materials, fabric surface trimming, etc., which can solve the problems of shortening baking time, decreasing fabric strength, and poor fabric treatment effect, and improving the hand feeling. Softness, reduce crystallinity, improve hand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

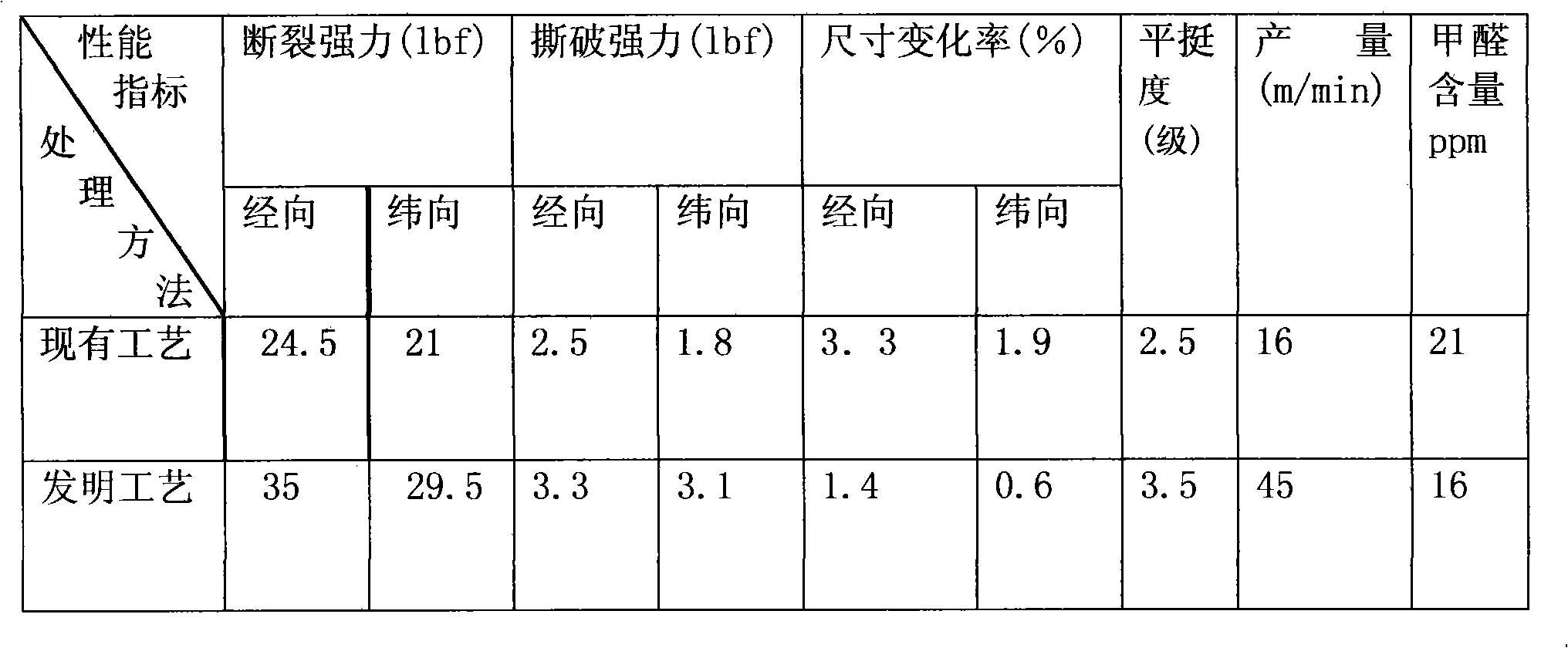

[0013] Example 1: Now the yarn count is 14×14, the specification is 54×54, and the gram weight is 170g / m 2 Linen fabrics as an example.

[0014] The anti-shrinkage and anti-wrinkle post-treatment process of linen fabric includes the linen fabric after padding and finishing working solution, and the process steps are low-temperature drying, high-temperature baking, drum machine washing, drum drying and pre-shrinking process. Specifically:

[0015] 1. Low temperature drying

[0016] It is carried out on a high-temperature setting machine. According to the weight and strength of the cloth, the oven temperature is 80°C, and the time is 100 seconds, so that the surface of the fabric and the inside of the fiber can be cured gently at the same time, and the amount of finishing adsorbed is uniform, avoiding over-crosslinking of the finishing working solution. Fast happens.

[0017] 2. High temperature baking

[0018] It is carried out in a baking machine. According to the weight a...

Embodiment 2

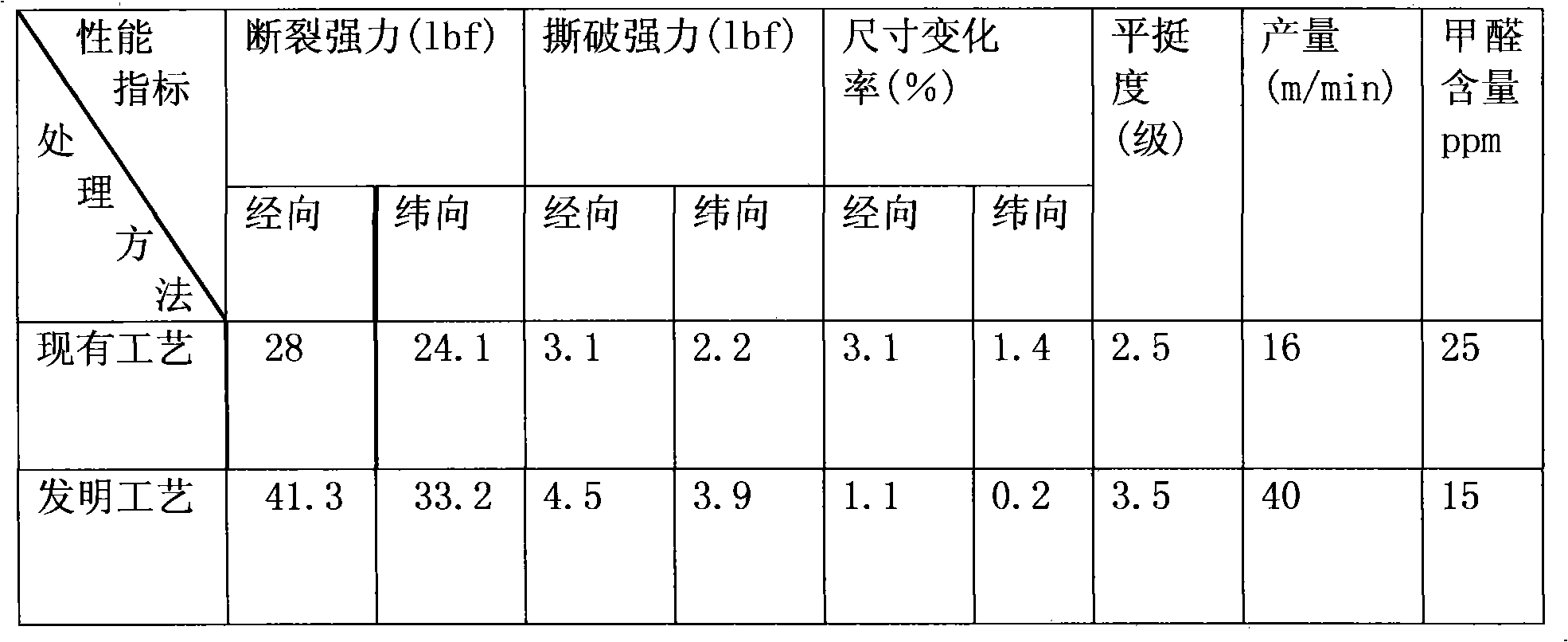

[0027] Example 2: Now the yarn count is 12×12, the specification is 48×48, and the gram weight is 225g / m 2 Linen fabrics as an example.

[0028] Process step and condition are with embodiment 1.

[0029] According to the cloth weight and strength, the difference is: the pre-drying temperature is set to 90°C, the pre-drying time is set to 90 seconds, the baking temperature is set to 150°C, the baking time is set to 90 seconds, and the tumbler is machine washed and dried. The tumble drying time was 45 minutes.

[0030] 12×12, 48×48, gram weight 225g / m produced according to the above process 2 The linen products, after 3 times of washing, the test data are as follows:

[0031]

Embodiment 3

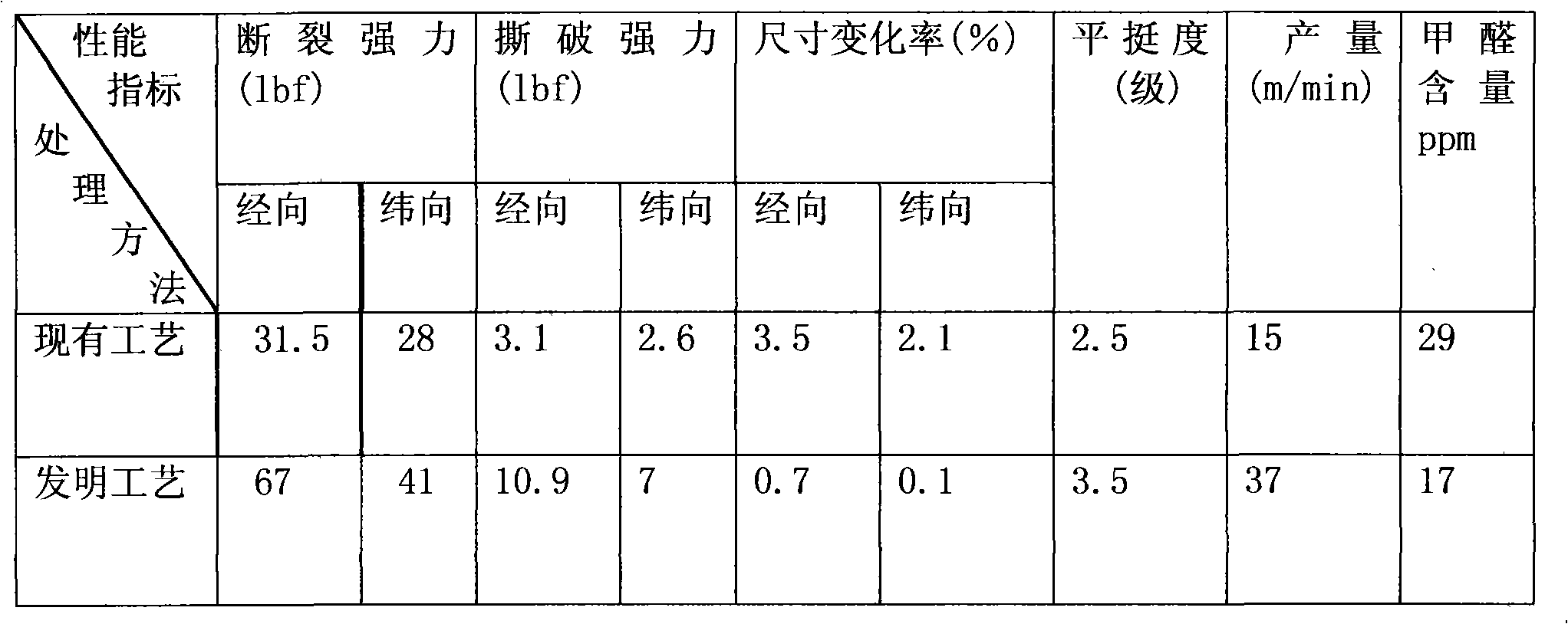

[0032] Embodiment 3: Now use yarn count 9×9, specification 42×42, gram weight 260g / m 2 Linen fabrics as an example.

[0033] Process step and condition are with embodiment 1.

[0034] According to the cloth weight and strength, the difference is: the pre-drying temperature is set to 100°C, the pre-drying time is set to 80 seconds, the baking temperature is set to 155°C, the baking time is set to 80 seconds, and the tumbler is machine washed and dried. The drum drying time was 60 minutes.

[0035] 9×9, 42×42 produced according to the above process, and the weight is 260g / m 2 The linen products, after 3 times of washing, the test data are as follows:

[0036]

[0037] The data in the above three tables show that:

[0038] The linen fabric treated by the invention is superior to the products in the prior art, and has good anti-shrinkage and anti-wrinkle performance, good fabric strength, and the reliability and stability of quality reach an advanced level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com