Ultrasonic spray tunnel furnace and method used for preparing large-area tin dioxide transparent conductive film

A technology of ultrasonic spray and tunnel furnace, applied in the direction of furnace, circuit, furnace type, etc., can solve the problems of high nozzle temperature, uneven film formation, difficult internal pressure control, etc., and achieve the effect of simple structure and reduced corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

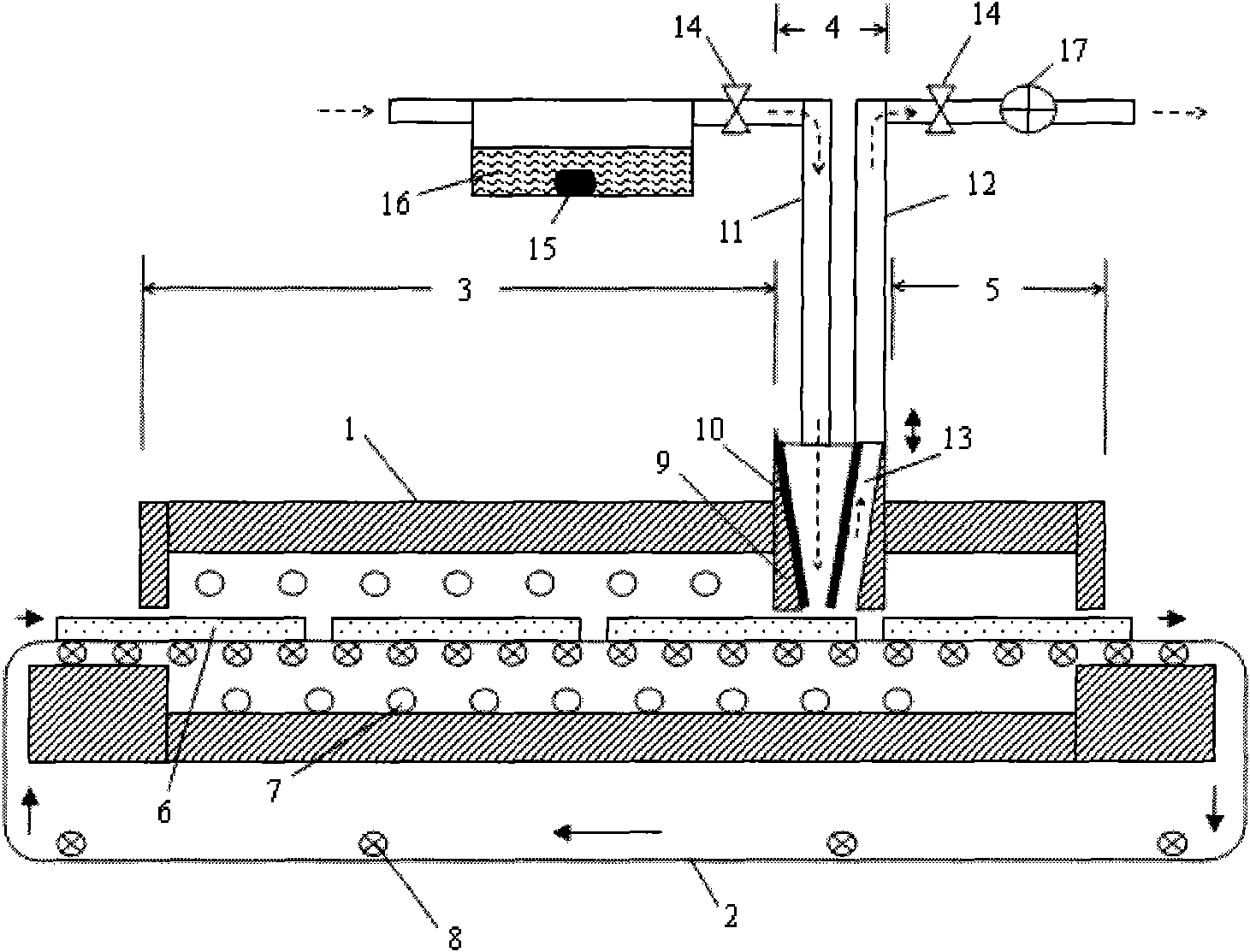

[0020] Embodiment 1: Ultrasonic spray tunnel furnace

[0021] With reference to the accompanying drawings: an insulation layer 1 is provided outside the tunnel furnace, and the tunnel furnace includes a heating zone 3, a working zone 4 and an annealing and heat preservation zone 5. The nozzles provided in the working area 4 are connected to an ultrasonic fogger 15 . A heating pipe 7 is arranged in the spray tunnel furnace, and a roller 8 is installed in the furnace, and a conveying mesh belt 2 is installed on the roller 8, and the substrate material 6 is placed on the conveying mesh belt 2 for transmission. The substrate material 6 is heated in the heating zone 3 , deposited in the working zone 4 , and annealed and cooled in the annealing and holding zone 5 . The temperature rise, working area temperature and annealing holding area temperature are all monitored by computer.

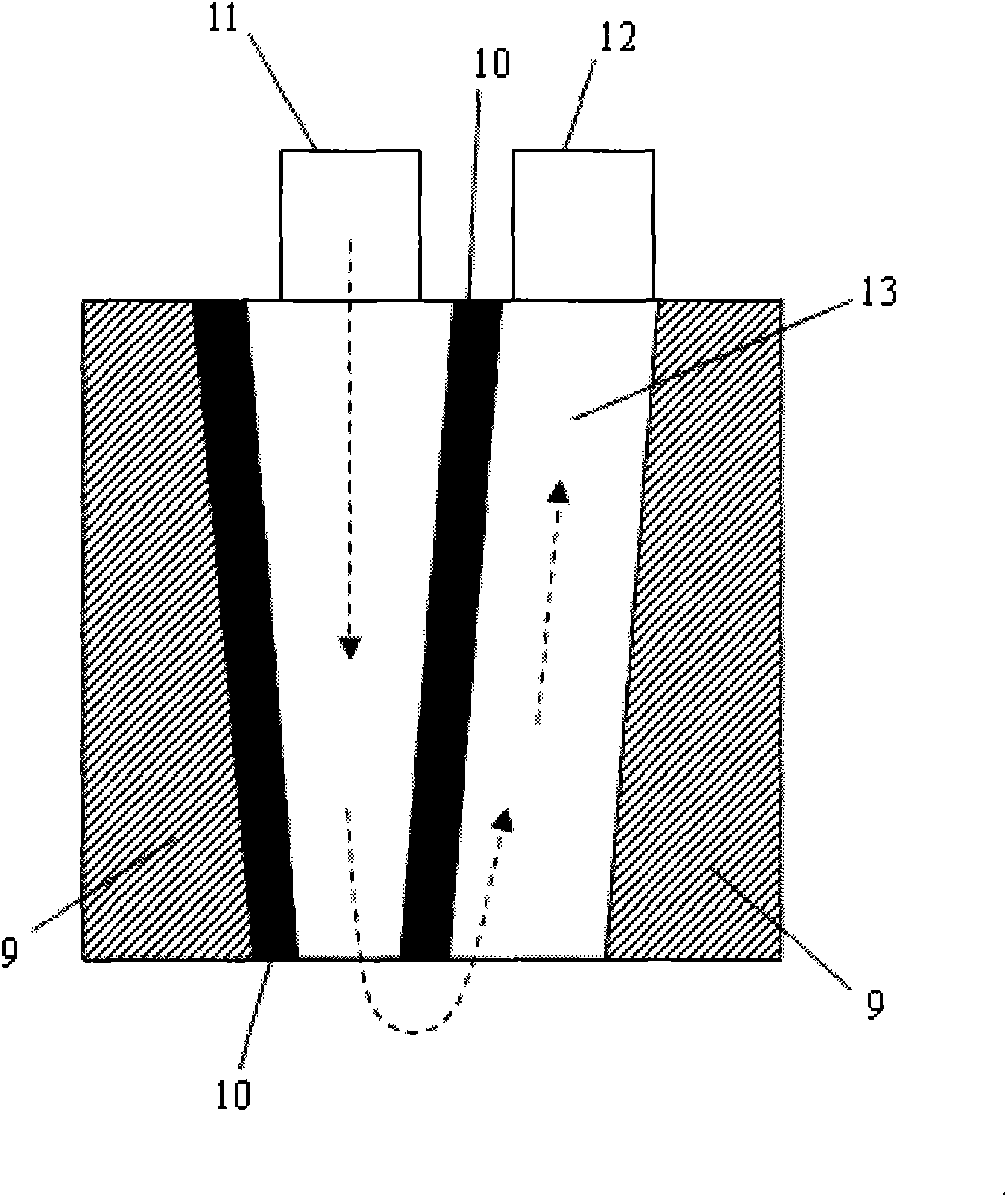

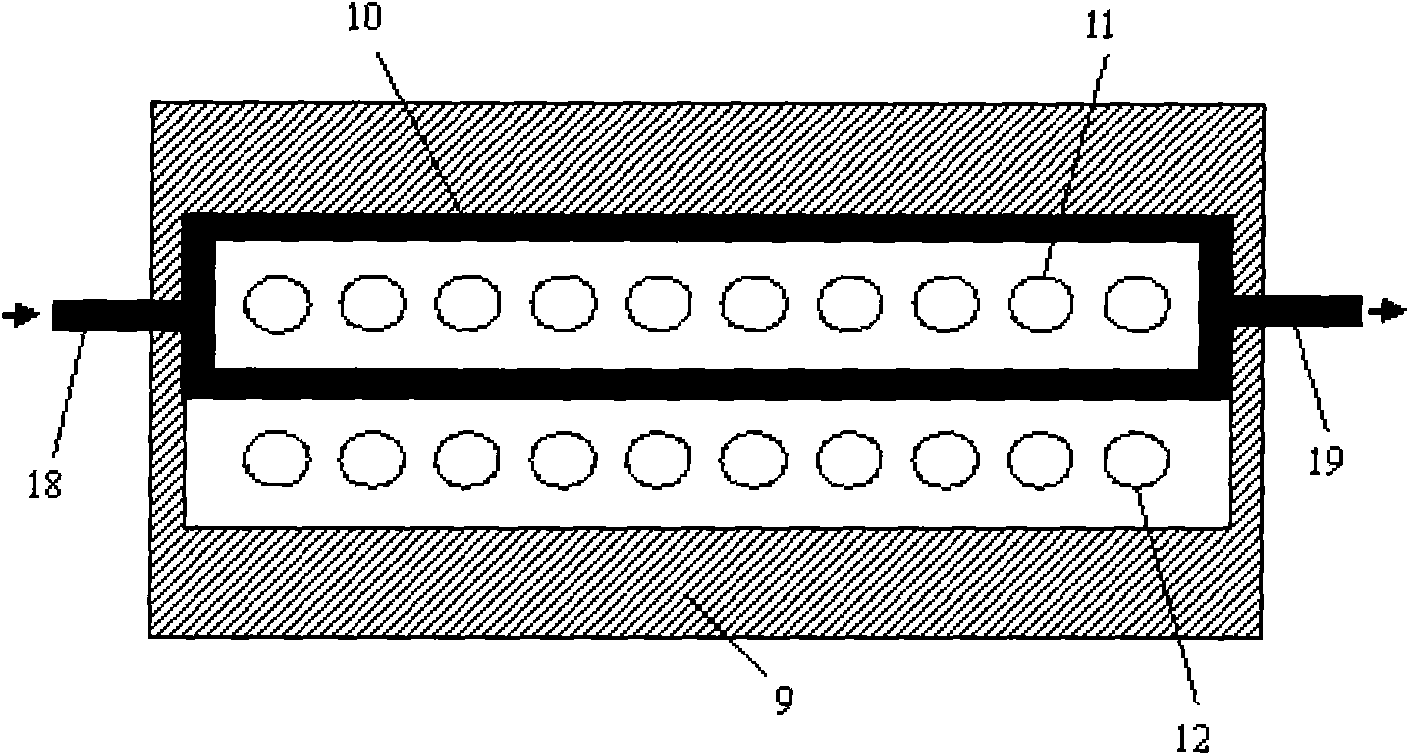

[0022] A nozzle insulation layer 9 is arranged outside the nozzle, and a nozzle water cooling layer ...

Embodiment 2

[0024] The method for preparing large-area transparent conductive film by ultrasonic spray method comprises the following steps:

[0025] (1) according to prior art preparation F / Sn molar percentage is the solution of 1%~10%; Pack into the ultrasonic fogger that is connected with nozzle and fog;

[0026] (2) The substrate material is carried by the conveyor belt into the tunnel furnace and heated in the heating zone;

[0027] (3) The substrate material is conveyed into the working area by the conveyor network, and the temperature is kept constant at 300°C to 500°C. The nozzle sprays the fogged mist evenly on the substrate material, and the entire surface of the substrate material 6 will deposit transparent conductive material. Thin film, the waste gas after reaction is pumped out from the waste gas discharge pipe by the suction pump;

[0028] (4) The substrate material is sent to the annealing and heat preservation zone by the conveyor belt for annealing and cooling.

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com