Method of cooling hot forged part, apparatus therefor, and process for producing hot forged part

A cooling device and component technology, applied in heating/cooling equipment, forging/pressing/hammer devices, manufacturing tools, etc., can solve the problems of reduced machinability, energy saving, etc., and achieve good cold workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

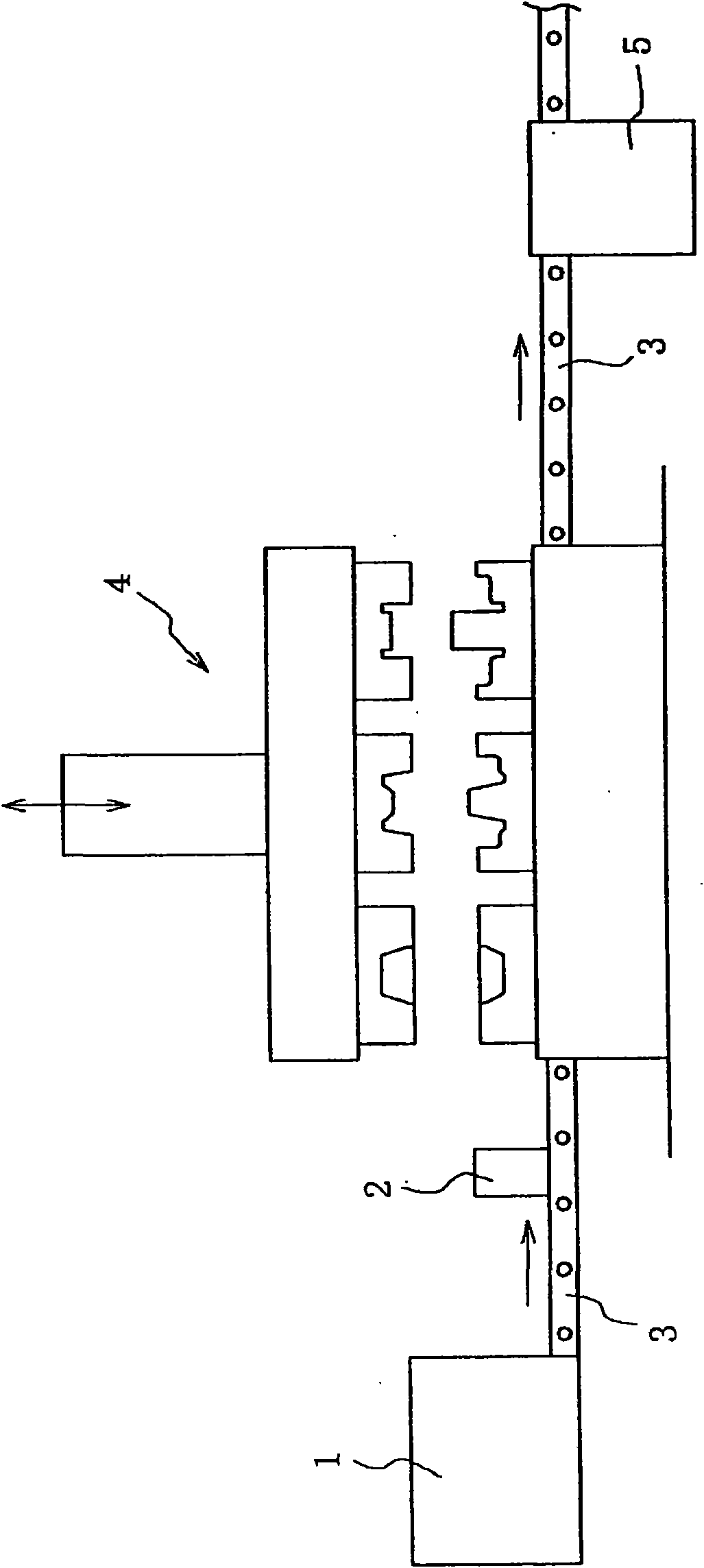

[0089] The steel with the chemical composition shown in Table 1 was melted in a vacuum melting furnace and cast into a 100 kg steel ingot. Next, the steel ingot is made into a 65mmφ bar steel by hot forging, and then imported figure 1 In the shown hot forging equipment.

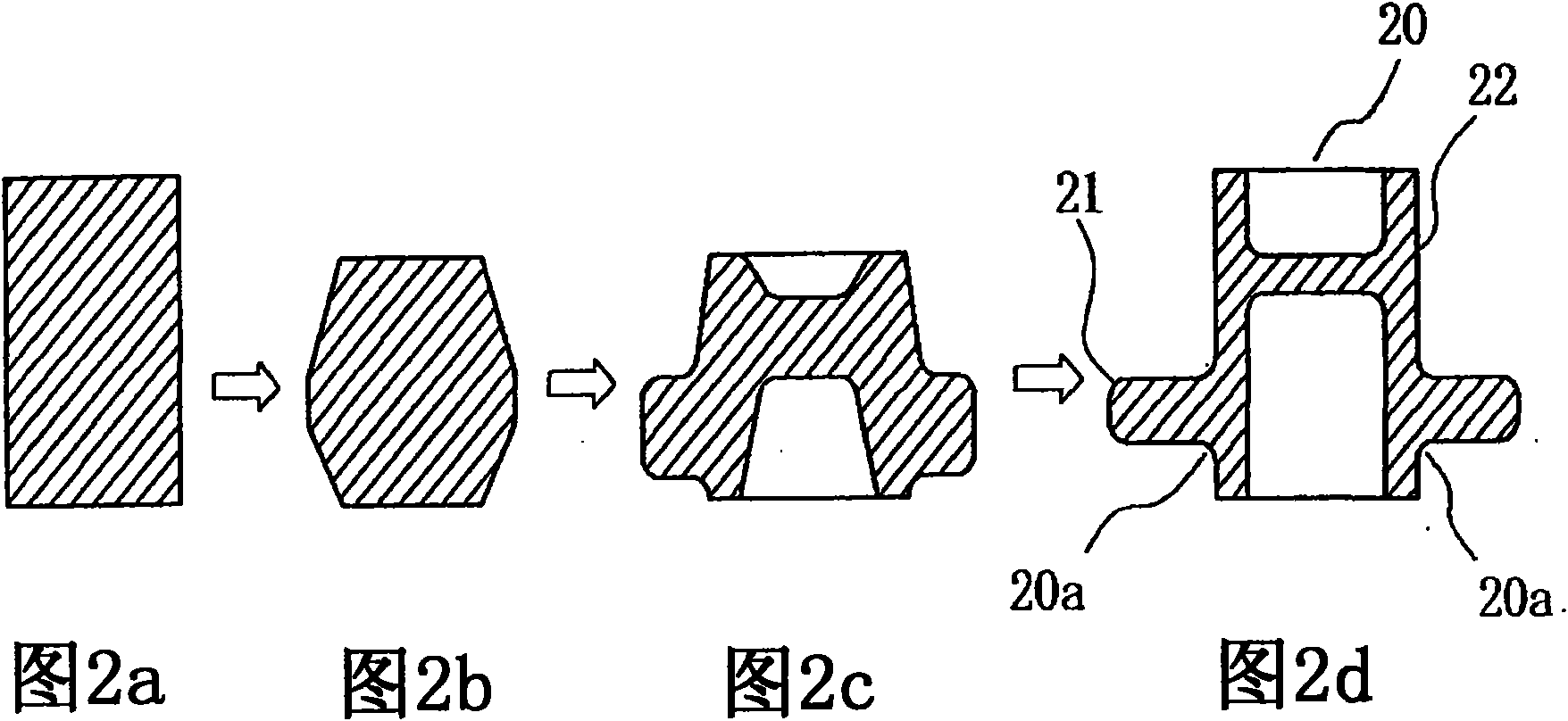

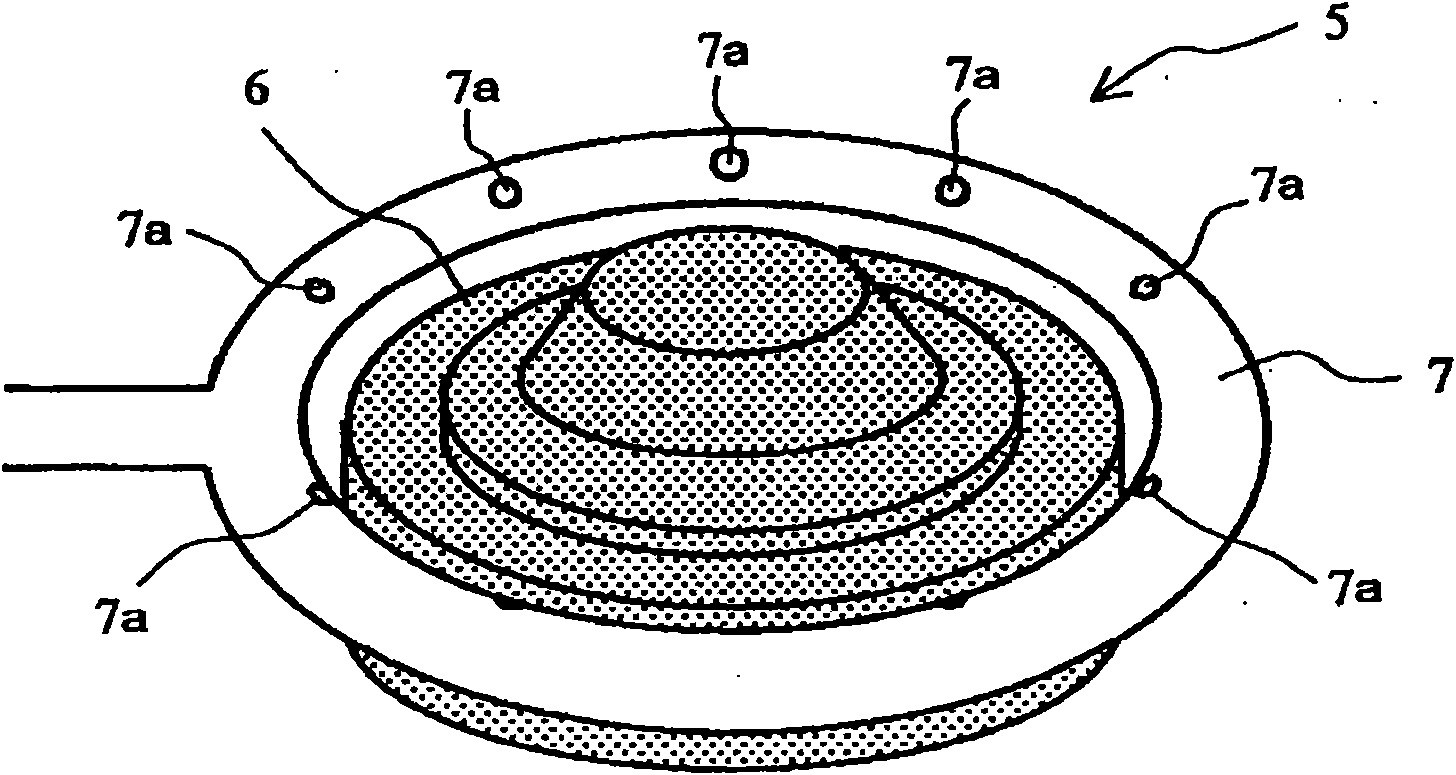

[0090] First, after heating the bar steel to 1200°C in the heating furnace 1, implement the following steps in the hot forging machine 4: Figure 2b , Figure 2c , Figure 2d shown in the three-stage hot forging, formed as Figure 2d Shown is a hot forged member 20 with a flange. The shaft diameter of the flange root of the hot forged member was 80 mm. The forged product 20 was immediately carried into a cooling device, and the flange root portion (the boundary portion between the flange portion and the shaft portion) 20a was locally partially cooled by cooling water at a flow rate of 25 l / min, and then allowed to cool. At this time, as a cooling device, Invention Example 1 used Image 6 The cooling de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com