Liquid dairy product rich in lactoferrin and preparation method thereof

A technology for lactoferrin and dairy products, applied in dairy products, milk preparations, food preparation, etc., can solve problems such as lactoferrin heat stability, achieve the effect of expanding sales cycle, improving anemia symptoms, and regulating absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

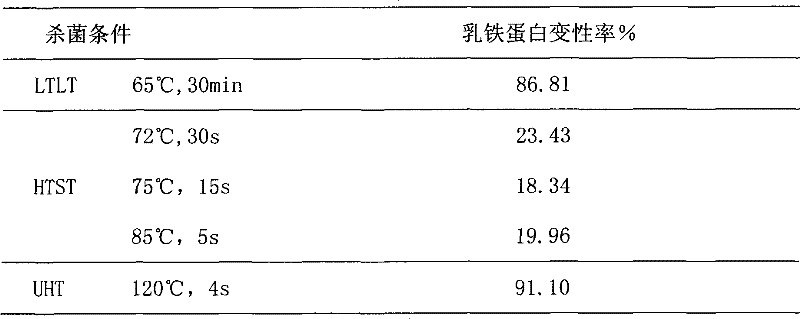

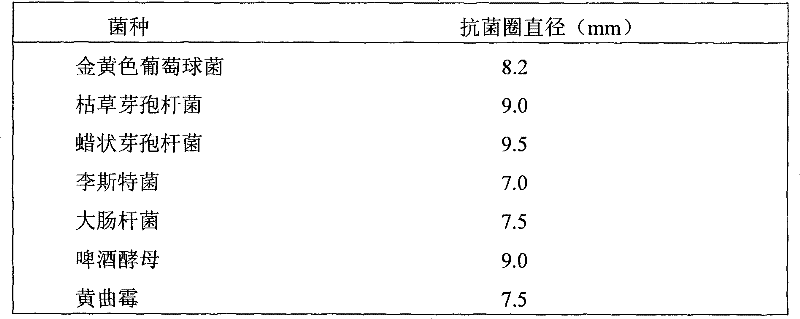

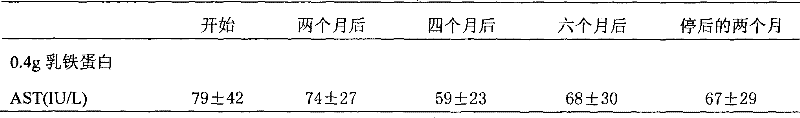

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Formula: 1000 parts by weight of the dairy product of the present invention, including 994 parts of milk, 5 parts of lactoferrin, 1 part of dry ester,

[0048] The preparation method is as follows:

[0049] (1) The raw milk whose temperature does not exceed 8°C is used to remove mechanical impurities in the raw milk through a milk cleaning process;

[0050] (2) Pasteurize the cleaned raw milk at 72°C for 10 seconds, and cool the pasteurized raw milk to below 8°C;

[0051] (3) Formulated milk composition

[0052] (4) Homogenization: raise the temperature of the milk composition to 65°C, and the homogenization pressure is 200bar

[0053] (5) Sterilize the prepared milk composition at 121°C / 4 seconds, and then cool the sterilized milk composition below 25°C;

[0054] (6) adding sterilized lactoferrin to the cooled sterilized milk composition;

[0055] (7) Carry out aseptic filling.

Embodiment 2

[0057] Formula: 1000 parts by weight of the dairy product of the present invention, wherein 300 parts of milk, 1 part of lactoferrin, 1 part of xanthan gum, and the balance is water.

[0058] The preparation method is as follows:

[0059](1) The raw milk whose temperature does not exceed 8°C is used to remove mechanical impurities in the raw milk through a milk cleaning process;

[0060] (2) Pasteurize the cleaned raw milk at 90°C for 15 seconds, and cool the pasteurized raw milk to below 8°C;

[0061] (3) Formulated milk composition

[0062] (4) Homogenization: raise the temperature of the milk composition to 65°C, and the homogenization pressure is 200bar

[0063] (5) Sterilize the prepared milk composition at 150°C / 15 seconds, and then cool the sterilized milk composition below 25°C;

[0064] (6) adding sterilized lactoferrin to the cooled sterilized milk composition;

[0065] (7) Carry out aseptic filling.

Embodiment 3

[0067] Formula: 1000 parts by weight of the dairy product of the present invention, wherein 998 parts of milk, 0.1 part of lactoferrin, 1 part of xanthan gum, and the balance is water.

[0068] The preparation method is as follows:

[0069] (1) The raw milk whose temperature does not exceed 8°C is used to remove mechanical impurities in the raw milk through a milk cleaning process;

[0070] (2) Pasteurize the cleaned raw milk at 72°C for 5 seconds, and cool the pasteurized raw milk to below 8°C;

[0071] (3) Formulated milk composition

[0072] (4) Homogenization: raise the temperature of the milk composition to 65°C, and the homogenization pressure is 200bar

[0073] (5) Sterilize the prepared milk composition at 150°C / 15 seconds, and then cool the sterilized milk composition below 25°C;

[0074] (6) adding sterilized lactoferrin to the cooled sterilized milk composition;

[0075] (7) Carry out aseptic filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com