High-dispersibility isolated soybean protein and preparation method thereof

A technology of soybean protein isolate and high dispersibility, which is applied in the field of high dispersity soybean protein isolate and its preparation, and can solve the problems of insufficient protein content and unsuitability for application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

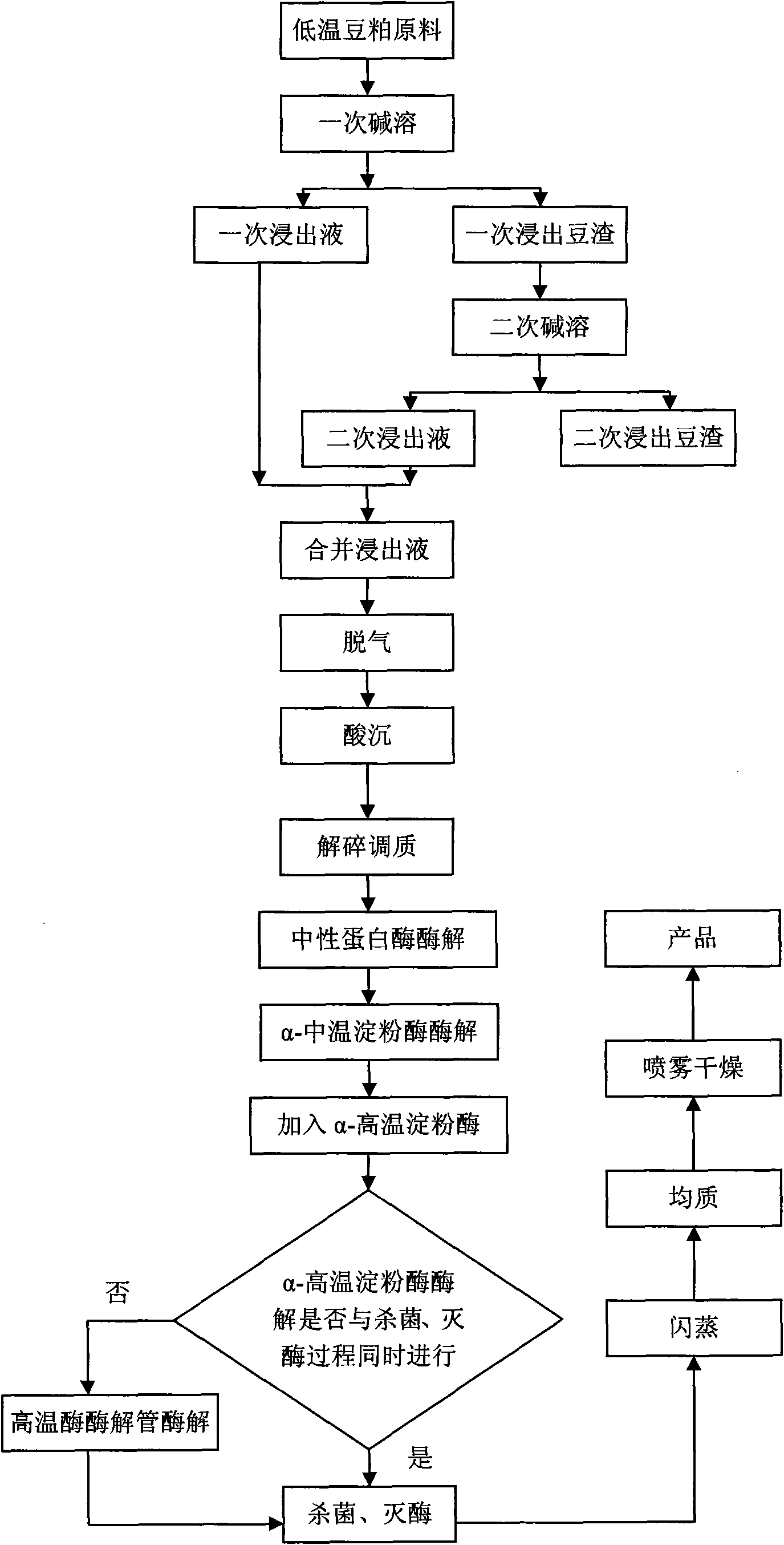

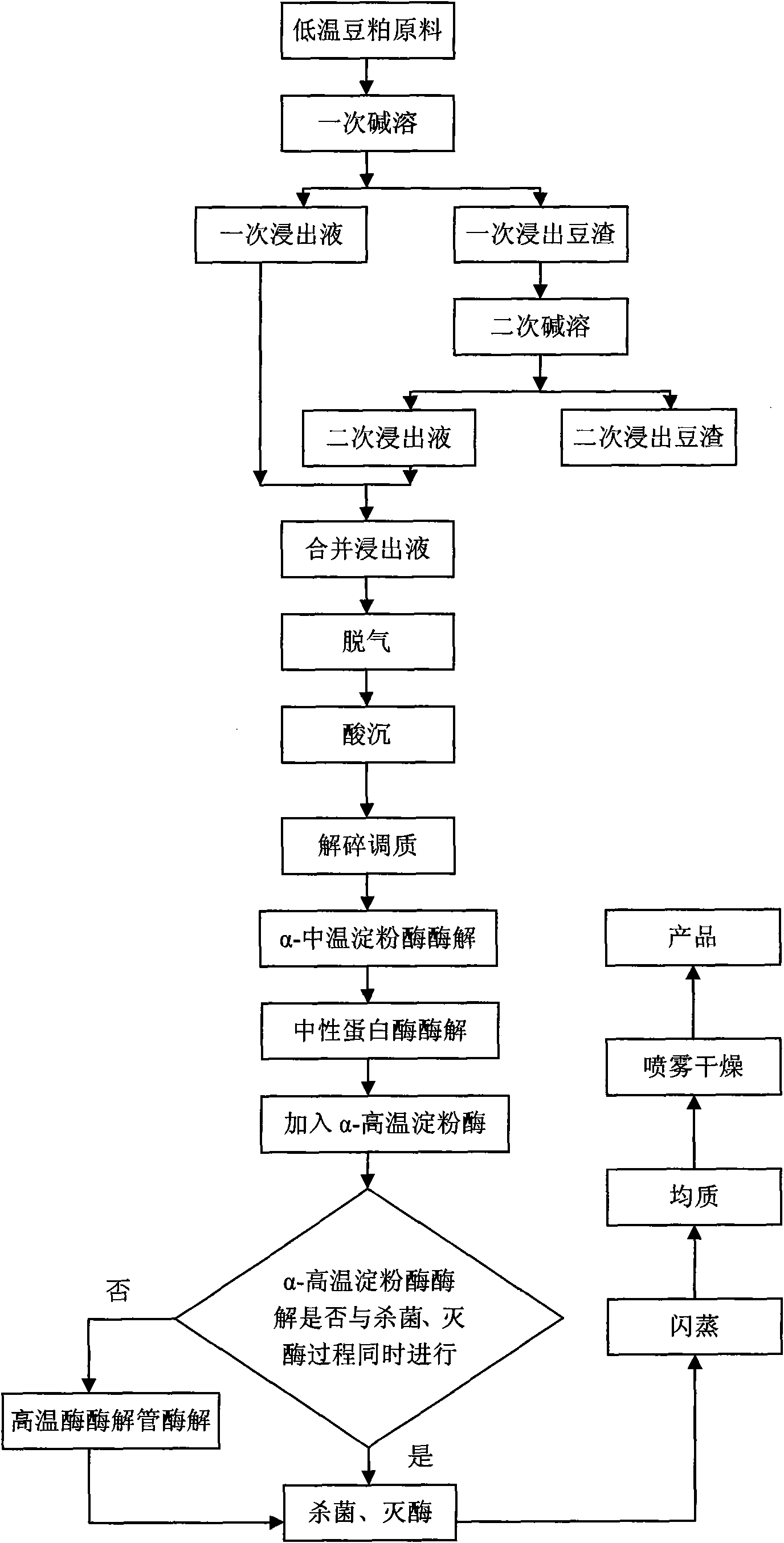

Method used

Image

Examples

Embodiment 1

[0046] 1600 kilograms of low-temperature defatted soybean meal raw materials and water at 48° C. are formulated into the first mixture in the leaching tank according to the weight ratio of water and raw materials of 9: 1, and the pH of the first mixture is adjusted by sodium hydroxide with a concentration of 29%-30%. Adjust it to 7.2-7.6, stir the first mixture adjusted by pH at a constant speed, keep it for 20 minutes, and separate the first mixture by a separator to obtain 10300 kg of protein liquid extracted once in the liquid phase and 3020 kg of bean dregs extracted once in the solid phase. The main components of the liquid phase are soluble protein, carbohydrates and salt, and the concentration of the protein in the first-time leaching protein solution is 7-8% (weight ratio); the first-time leaching of bean dregs and water at 48 ° C are based on the weight ratio of water and first-time leaching of bean dregs It is 7: 1 and is formulated into the second mixture in the leac...

Embodiment 2

[0048]1600 kilograms of low-temperature defatted soybean meal raw materials and water at 48 ° C are formulated into the first mixture in the leaching tank according to the weight ratio of water and raw materials of 8: 1, and the pH of the first mixture is adjusted by sodium hydroxide with a concentration of 29%-30%. Adjust it to 7.2-7.6, stir the first mixture adjusted by pH at a constant speed, keep it for 25 minutes, and separate the first mixture by a separator to obtain 10270 kg of protein liquid extracted in the liquid phase and 3060 kg of bean dregs extracted in the solid phase. The main components of the liquid phase are soluble protein, carbohydrates and salt, and the concentration of the protein in the first-time leaching protein solution is 8-9% (weight ratio); the first-time leaching bean dregs and water at 48°C are mixed according to the weight ratio of water to the first-time leaching bean dregs It is 6: 1 and is formulated into the second mixture in the leaching t...

Embodiment 3

[0050] 1600 kilograms of low-temperature defatted soybean meal raw materials and water at 48 ° C are formulated into the first mixture in the leaching tank according to the weight ratio of water and raw materials of 7: 1, and the pH of the first mixture is adjusted by sodium hydroxide with a concentration of 29%-30%. Adjust it to 7.2-7.6, stir the first mixture adjusted by pH at a constant speed, keep it for 28 minutes, and separate the first mixture by a separator to obtain 10230 kg of protein liquid extracted in the liquid phase and 3120 kg of bean dregs extracted in the solid phase. The main components of the liquid phase are soluble protein, carbohydrates and salt, and the concentration of the protein in the first-time leaching protein solution is 7.5-8.5% (weight ratio); the first-time leaching of bean dregs and water at 48 ° C are based on the weight ratio of water to the first-time leaching of bean dregs It is 5: 1 and is formulated into the second mixture in the leachin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com