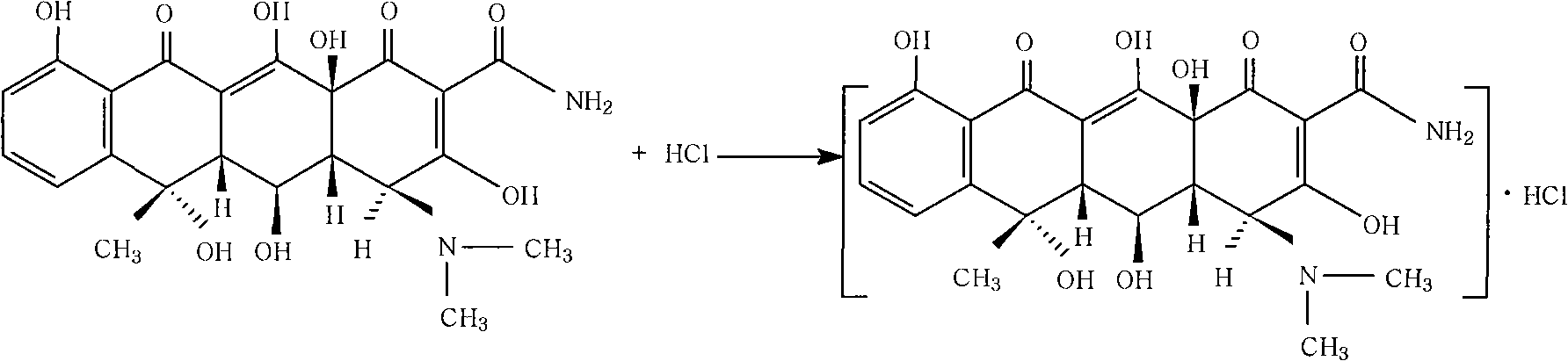

Production process of oxytetracycline dihydrate hydrochloride

A technology of oxytetracycline hydrochloride and production process, which is applied in the field of production process of large particle oxytetracycline hydrochloride, can solve the problems of low yield and low apparent density, achieve high apparent density, meet different requirements, and have good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Add isopropanol-n-butanol to the reaction kettle, control the temperature at 15-20°C, add hydrogen chloride-n-butanol, control the temperature at 22-28°C, add oxytetracycline under stirring until clear, add activated carbon and stir Decolorize for 5 minutes, press filter to obtain the solution, raise the temperature of the solution to 45-50°C and keep it warm for 1.5-2 hours, cool down to below 30°C, filter and wash with n-butanol, and vacuum-dry the crystal at below 90°C for 4 hours.

[0009]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com