Petroleum fracturing propping agent and preparation method thereof

A fracturing proppant and proppant technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well parts, etc., can solve problems such as narrowing of the firing range of petroleum proppant, sticking kiln rings, high price, etc. problem, to achieve the effect of structure densification, internal structure densification and reduction of breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation of the present invention will be described below in conjunction with the examples, but the following examples are only used to describe the present invention in detail, and do not limit the scope of the present invention in any way.

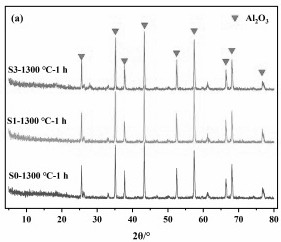

[0030] Al in the bauxite powder in the following examples 2 o 3 The content of silicon dioxide is 64.03%, the content of silicon oxide is 10.76%, and the content of iron oxide is 3.08%. The alumina content in the pulverized fine powder is 68.87%, the silicon oxide content is 13.88%, and the iron oxide content is 3.85%.

[0031] The following examples and comparative examples are some typical representative examples of the inventor in the research process, and list 1 is as follows:

[0032]

[0033] The preparation method that above embodiment and comparative example adopt are as follows:

[0034] 1) Get each raw material in proportion;

[0035] 2) mix each raw material;

[0036] 3) Granulation, feed the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com