Nanometer cobalt ion-doped titanic anhydride catalyst and preparation method thereof

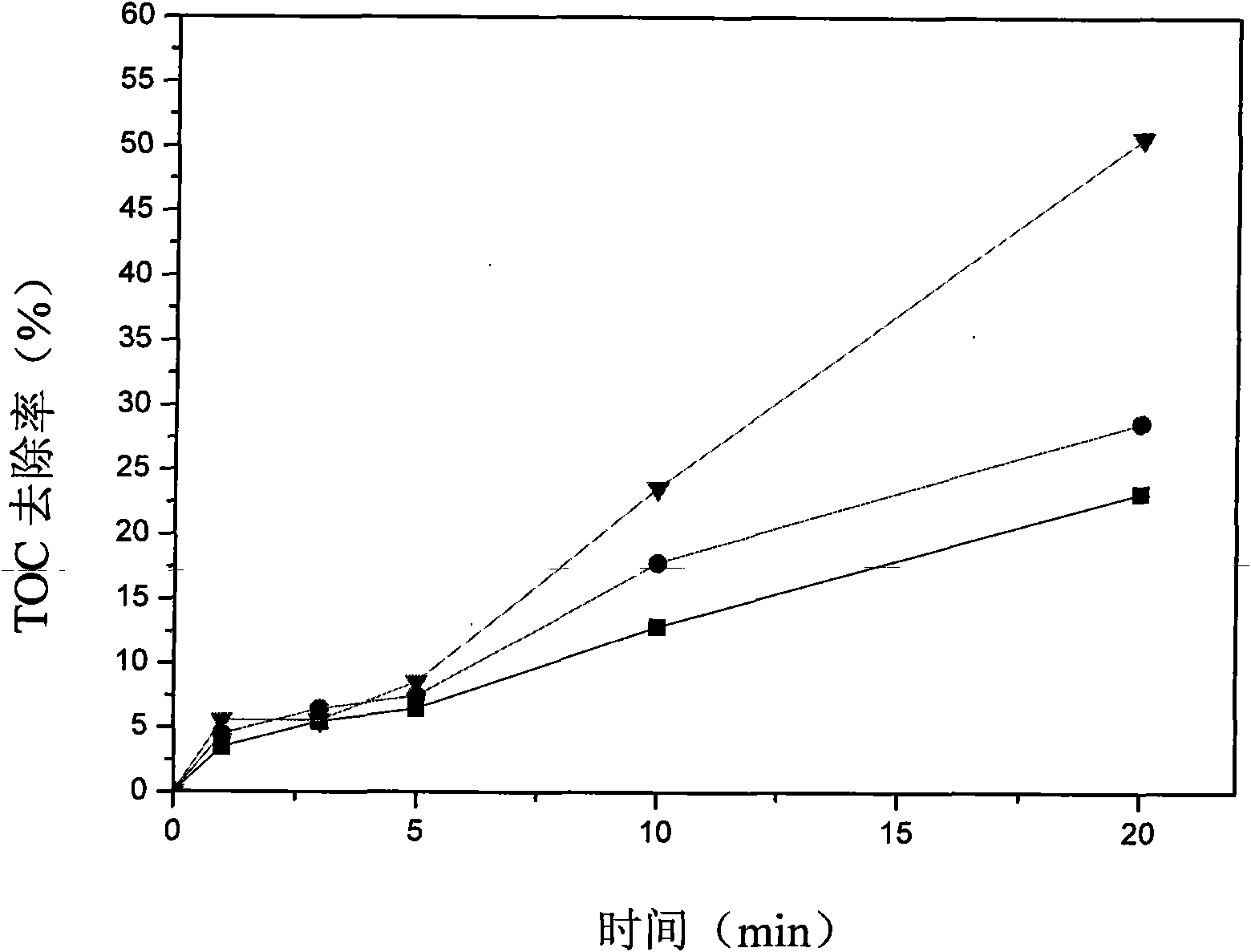

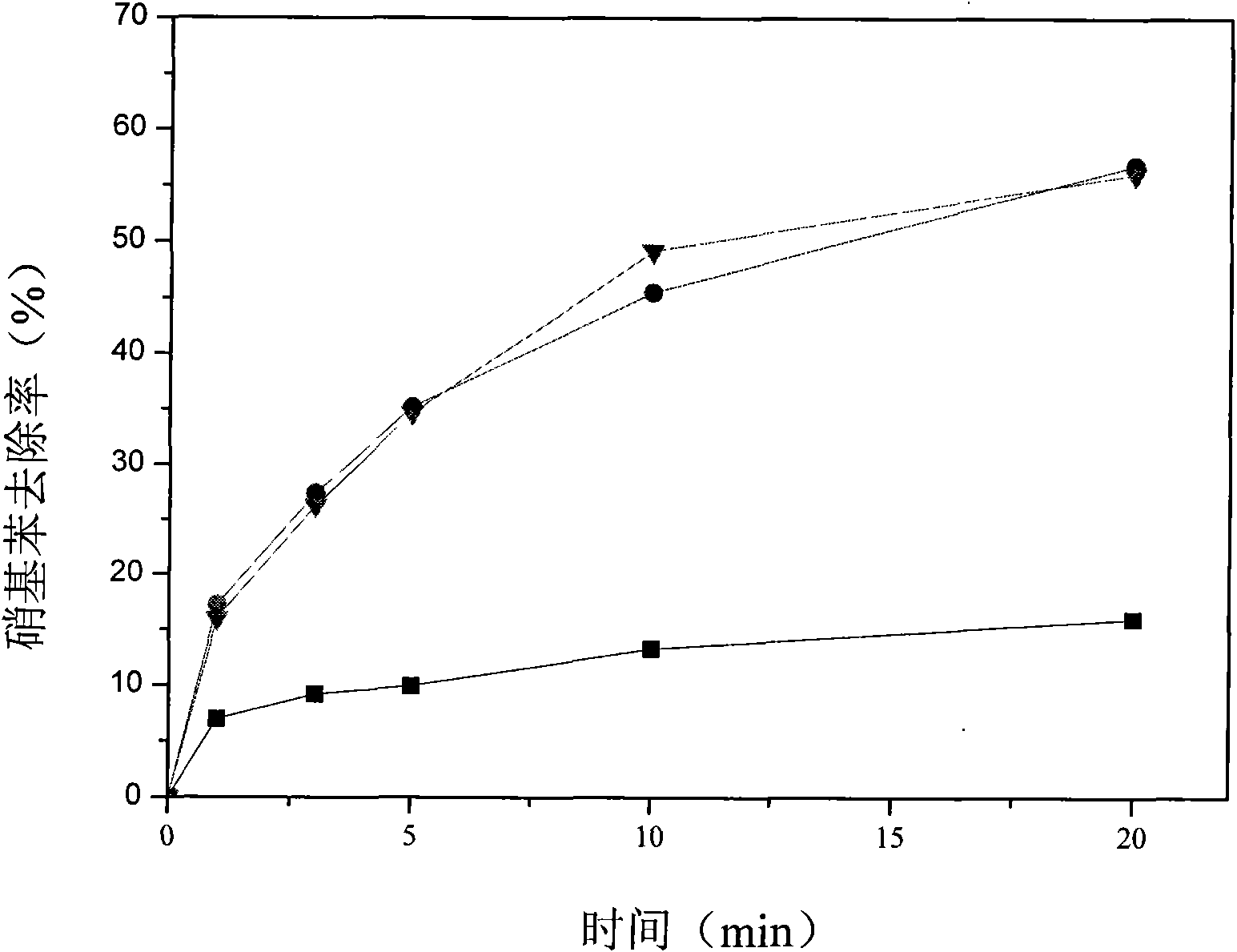

A titanium dioxide, nano-scale technology, applied in the field of titanium dioxide catalyst and its preparation, can solve the problem that the removal rate of TOC in the effluent is difficult to increase, and achieve the effect of improving the degradation rate of stable pollutants, simple and easy preparation method, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: the nano-scale cobalt ion-doped titanium dioxide catalyst of this embodiment is made of butyl titanate, absolute ethanol, cobalt chloride, concentrated hydrochloric acid and distilled water, wherein the volume ratio of butyl titanate and absolute ethanol is 1:4, the volume ratio of butyl phthalate to concentrated hydrochloric acid is 12:1, the molar ratio of Ti element in butyl titanate to Co element in cobalt chloride is 10-40:1, distilled water and butyl phthalate The volume ratio is 5:6.

[0017] The particle size of the catalyst in this embodiment is nanoscale. The nano-scale cobalt ion-doped titanium dioxide catalyst described in this embodiment is mainly used for catalytic ozonation treatment of drinking water, which can be processed by the existing catalytic ozonation method. In the aforementioned catalytic ozonation method, the catalyst adopts a one-time dosing method. Ozone is continuously added, and its process conditions are: the ozo...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass fraction of the concentrated hydrochloric acid is 36.5%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the molar ratio of Ti element in butyl titanate to Co element in cobalt chloride is 15-35:1. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com