Method and device for flushing vapor side of high-low pressure heater in large-sized heat-engine plant

A low-pressure heater and flushing device technology, applied in chemical instruments and methods, cleaning methods using liquids, cleaning methods and utensils, etc., can solve problems affecting the safety, reliability and economy of boiler equipment, prolong unit commissioning period, Reduce equipment reliability and other issues to shorten the commissioning period, reduce unplanned outages, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

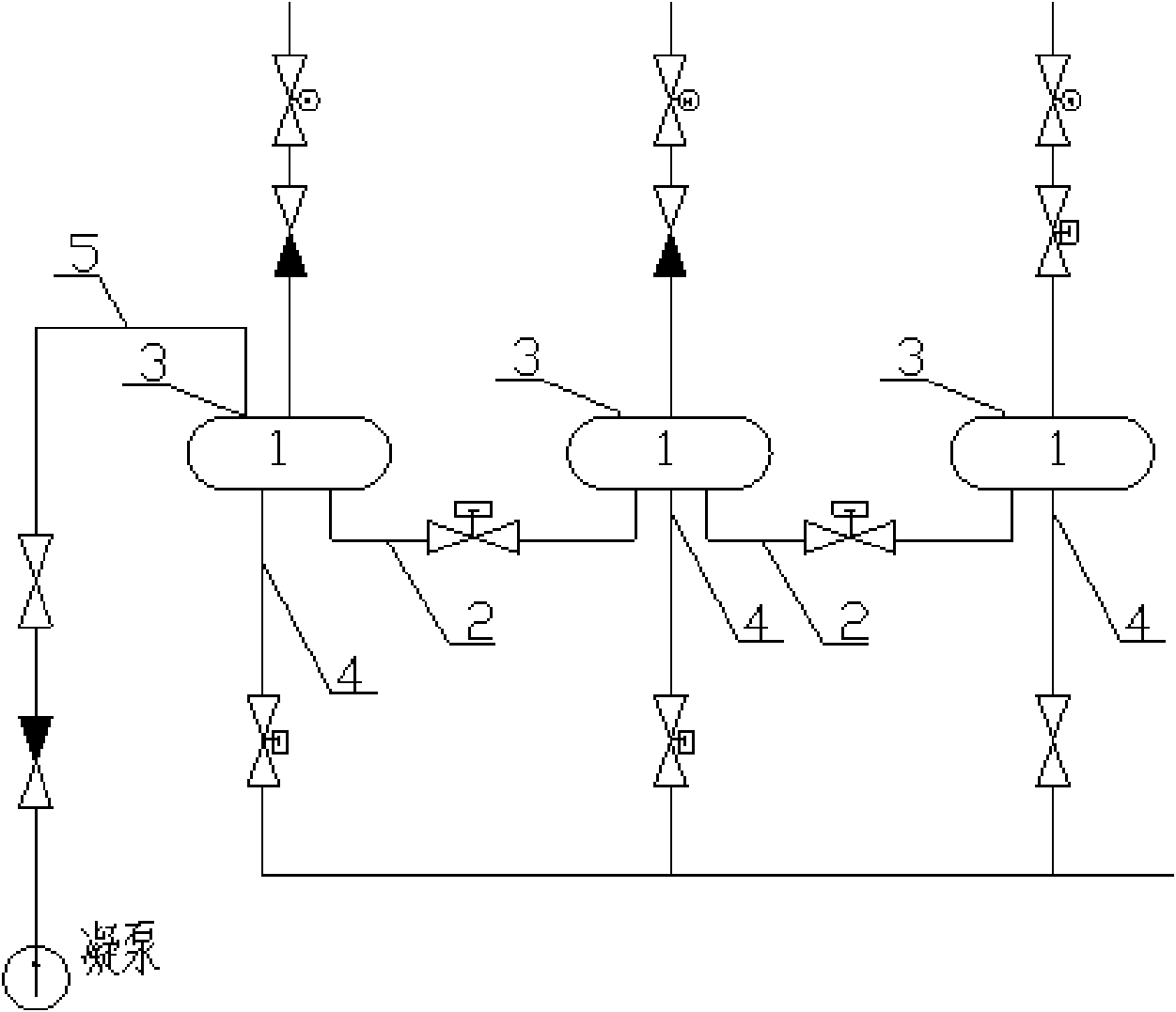

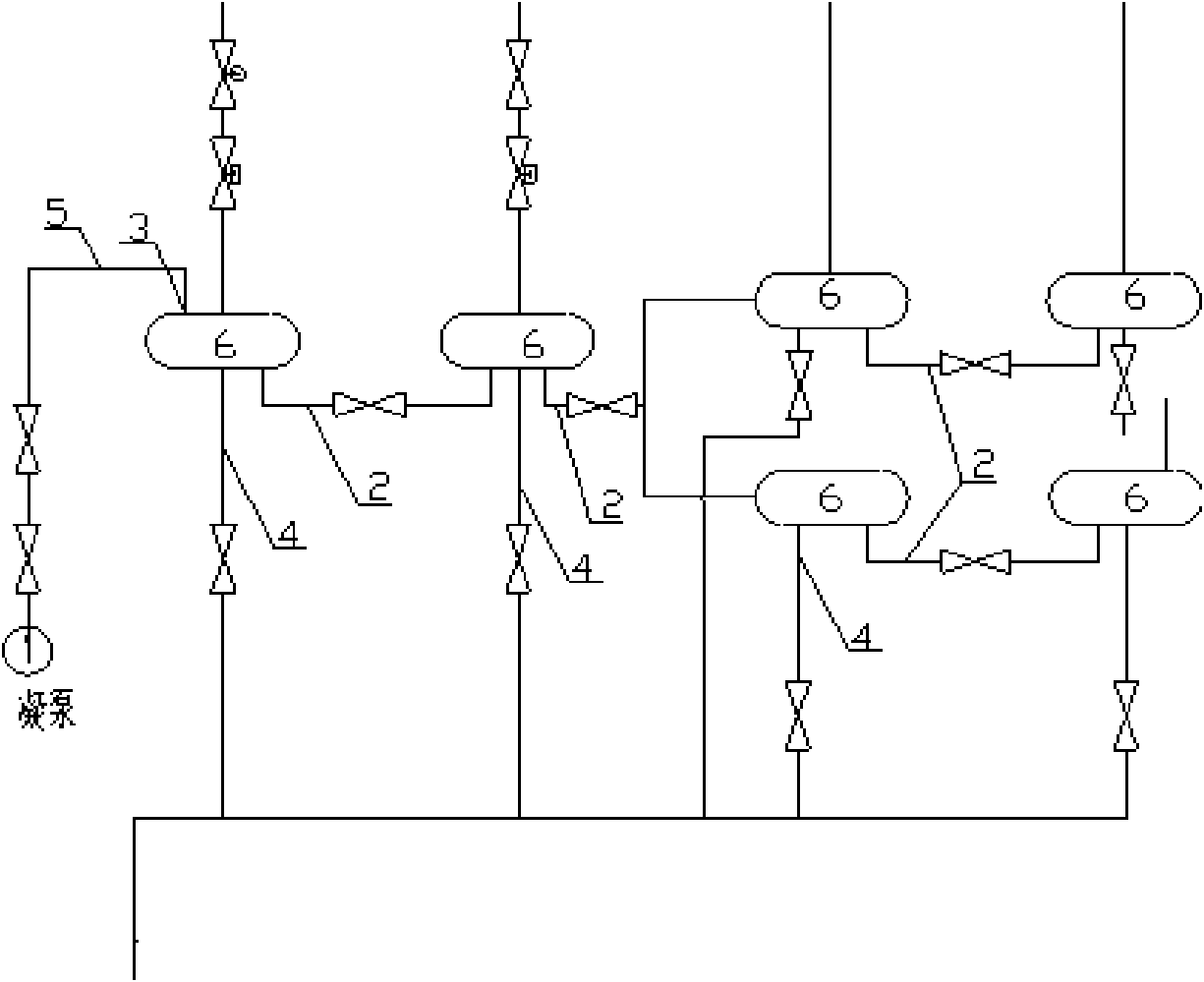

[0015] Embodiment 1: Taking three high-pressure heater systems 1 as an example, the steam side water flushing press figure 1 The steam side of more than one high-pressure heater system 1 is connected through a normal drain pipe 2 with a valve, and a safety door 3 on the steam side of one or each or each high-pressure heater system 1 is connected Water injection pipeline 5 (in this example, a water injection pipeline 5 is connected to the steam side safety door 3 of the first high-pressure heater system 1, that is, the first high-pressure heater system 1 along the drain flow direction), and the water injection pipeline 5 is connected to On the condensate pipes with valves, valves can also be installed independently on the water injection pipeline 5. When flushing, first close the steam extraction electric door, check door and drain valve in front of the steam extraction electric door of each high-pressure heater system 1 of the steam turbine. , close the valve connecting the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com