Process of integrally shaping U-shaped bifurcated pipe

A technology of integrally forming and bifurcated pipes, applied in the direction of manufacturing tools, metal processing equipment, other manufacturing equipment/tools, etc., can solve the problems of difficulty, welding stress concentration, pipe bursting, etc., and achieve the effect of not easy to burst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

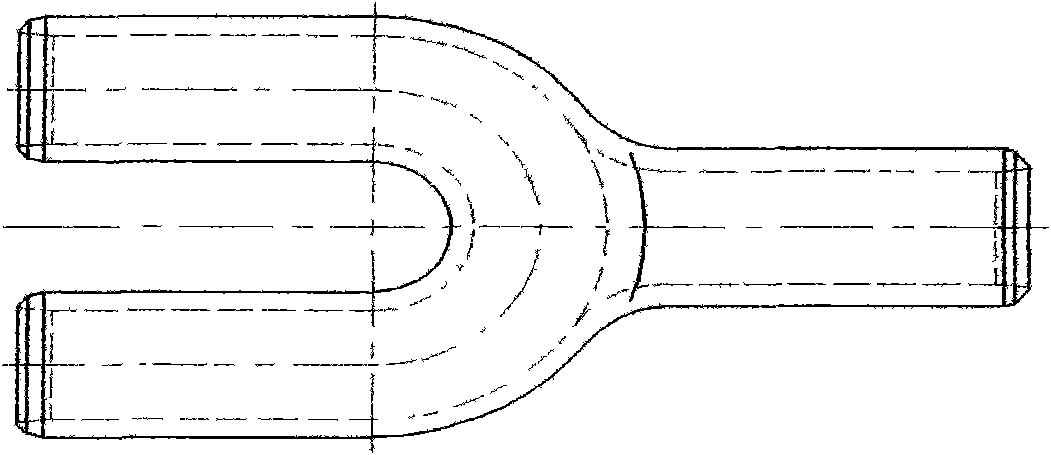

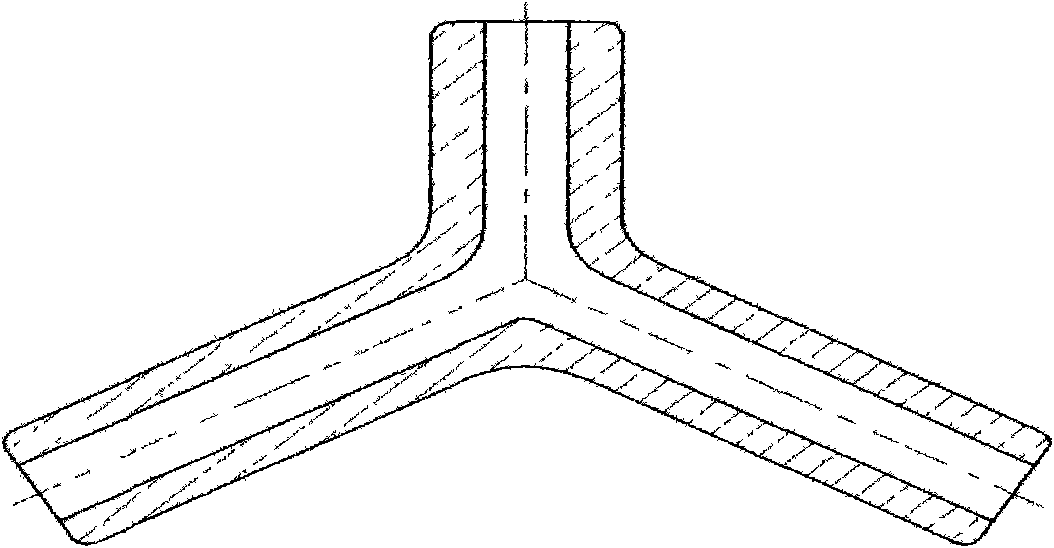

[0016] Using die forging and extrusion bending equipment to forge and extrude the U-shaped bifurcated pipe as a whole, firstly make a Y-shaped mold according to the size of the U-shaped bifurcated pipe to be processed, see figure 2 .

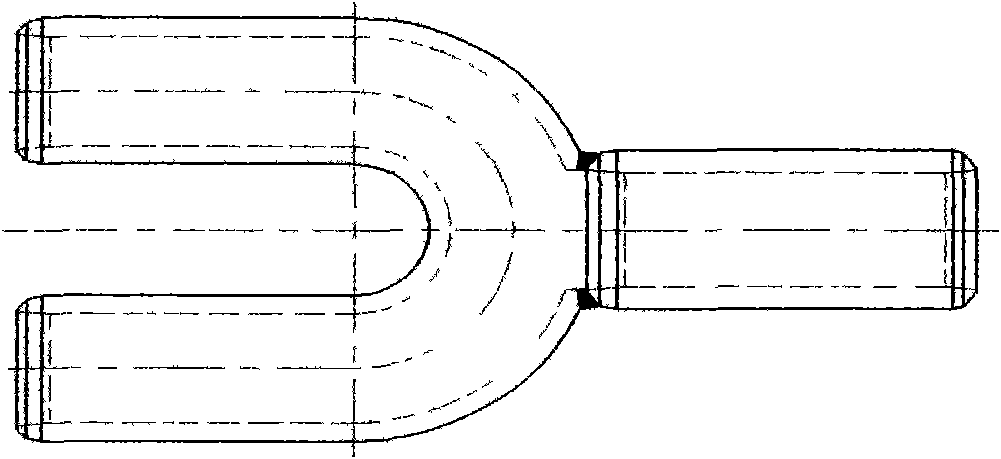

[0017] Heat the fallen material to 850-1200°C in an intermediate frequency heating furnace, then use the mold prepared above, use the forming die to form a friction press, and forge it into a Y-shaped bar, and then use a drilling device to drill a Y-shaped bar. The inner channel forms a Y-shaped tube, and then the V-shaped head of the Y-shaped tube is bent into a U shape by extrusion bending equipment to form a U-shaped bifurcated tube shape, see figure 1 , In the entire assembly line operation, the time from blanking to bending into a U-shaped tube after intermediate frequency heating is controlled within 60-90s.

[0018] The bent U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com