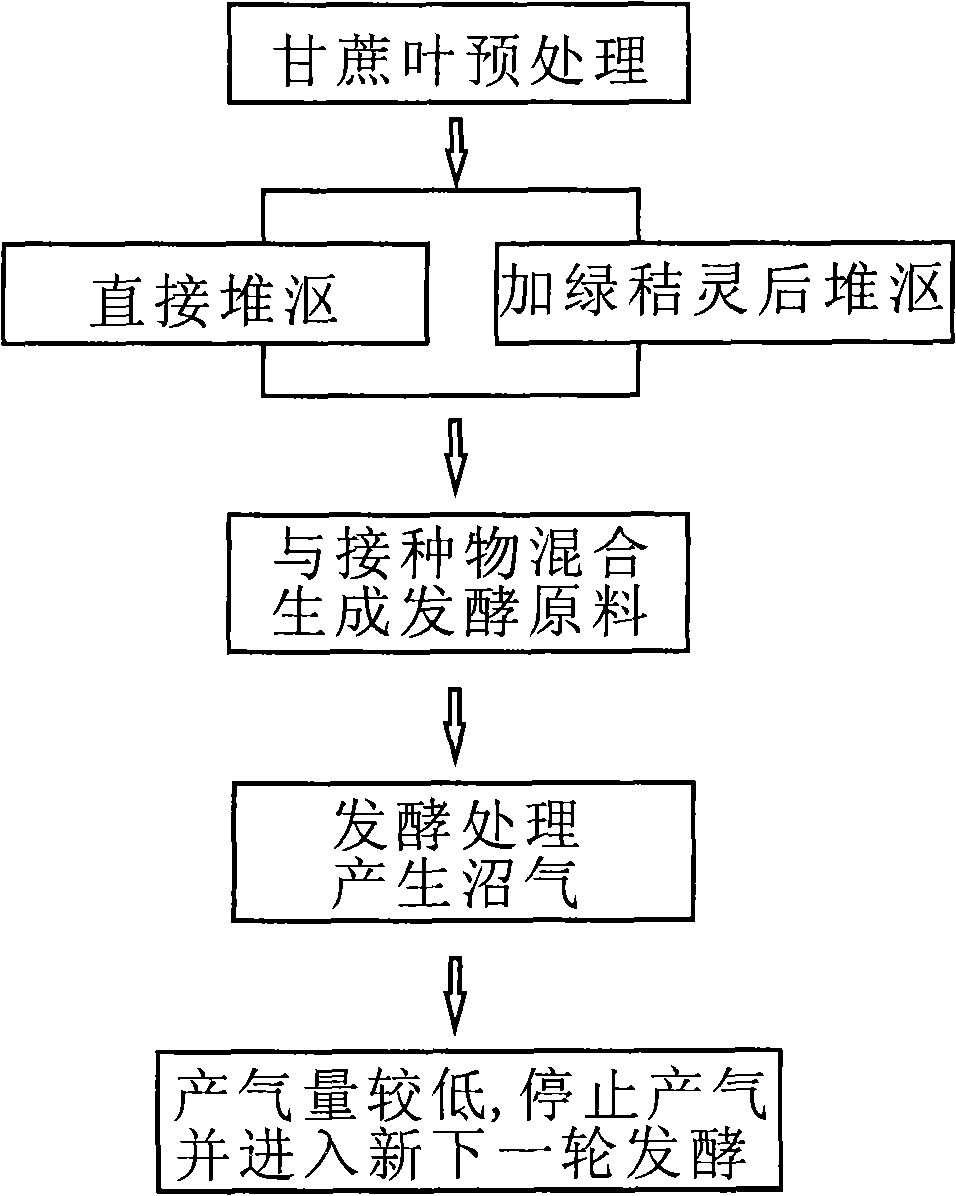

Method for preparing biogas by dry-fermenting sugarcane leaves as raw materials

A technology of dry fermentation of sugarcane leaves, applied in fermentation, waste fuel, climate sustainability, etc., can solve problems such as a large amount of smog, affecting road safety, and low crushing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0028] Example 2: A farmer uses sugarcane leaves to prepare biogas, and uses sugarcane leaves as raw materials to prepare biogas by dry fermentation. The specific steps are as follows.

[0029] (1) The pulverization process of raw material sugarcane leaf, the sugarcane leaf after harvesting is cut into the segment of 1~3cm;

[0030] (2) add water to adjust its water content to 62.5% in the sugarcane leaf 150kg of gained in step (1), moisten 22 hours;

[0031] (3) Dissolving 15 kg of N element material urea in water and then adding to the wetted sugarcane leaves in step (2), mixing to obtain a mixture, the carbon-nitrogen ratio of the mixture is 25: 1, and the water content is 67.5 %;

[0032] (5) 0.8kg green straw spirit is dissolved in water and added to the mixture obtained in step (3), adjust its water content to 77.5%, stir evenly and carry out stacking retting, after the stacking retting temperature reaches more than 50°C, keep for four sky;

[0033] (5) mix the mixtur...

Embodiment 3

[0036] Example 3: A farmer uses sugarcane leaves to prepare biogas, and uses sugarcane leaves as raw materials to prepare biogas by dry fermentation. The specific steps are as follows.

[0037] (1) The pulverization process of raw material sugarcane leaf, the sugarcane leaf after harvesting is cut into the segment of 1~3cm;

[0038] (2) add water to adjust its water content to 65% in the sugarcane leaf 150kg of gained in step (1), moisten 24 hours;

[0039] (3) dissolving 15 kg of N element material urea in water and then adding to the wetted sugarcane leaves in step (2), mixing to obtain a mixture, the carbon-nitrogen ratio of the mixture is 30: 1, and the moisture content is 70 %;

[0040] (6) Dissolve 1 kg of Green Straw Spirit in water and add it to the mixture obtained in step (3), adjust its water content to 80%, stir evenly and carry out stack retting, after the stack retting temperature reaches above 50°C, keep it for four days ;

[0041] (5) mix the mixture obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com