Assembled metal sound insulation chamber

A sound insulation room and assembled technology, which is applied in the direction of sound insulation, insulation layer, sealing device, etc., can solve the problems such as poor handling of the gap between modules, difficult disassembly and reassembly, and reduction of the overall sound insulation of the sound insulation room. Achieve the effects of easy reassembly, standardization of joints, good vibration and sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

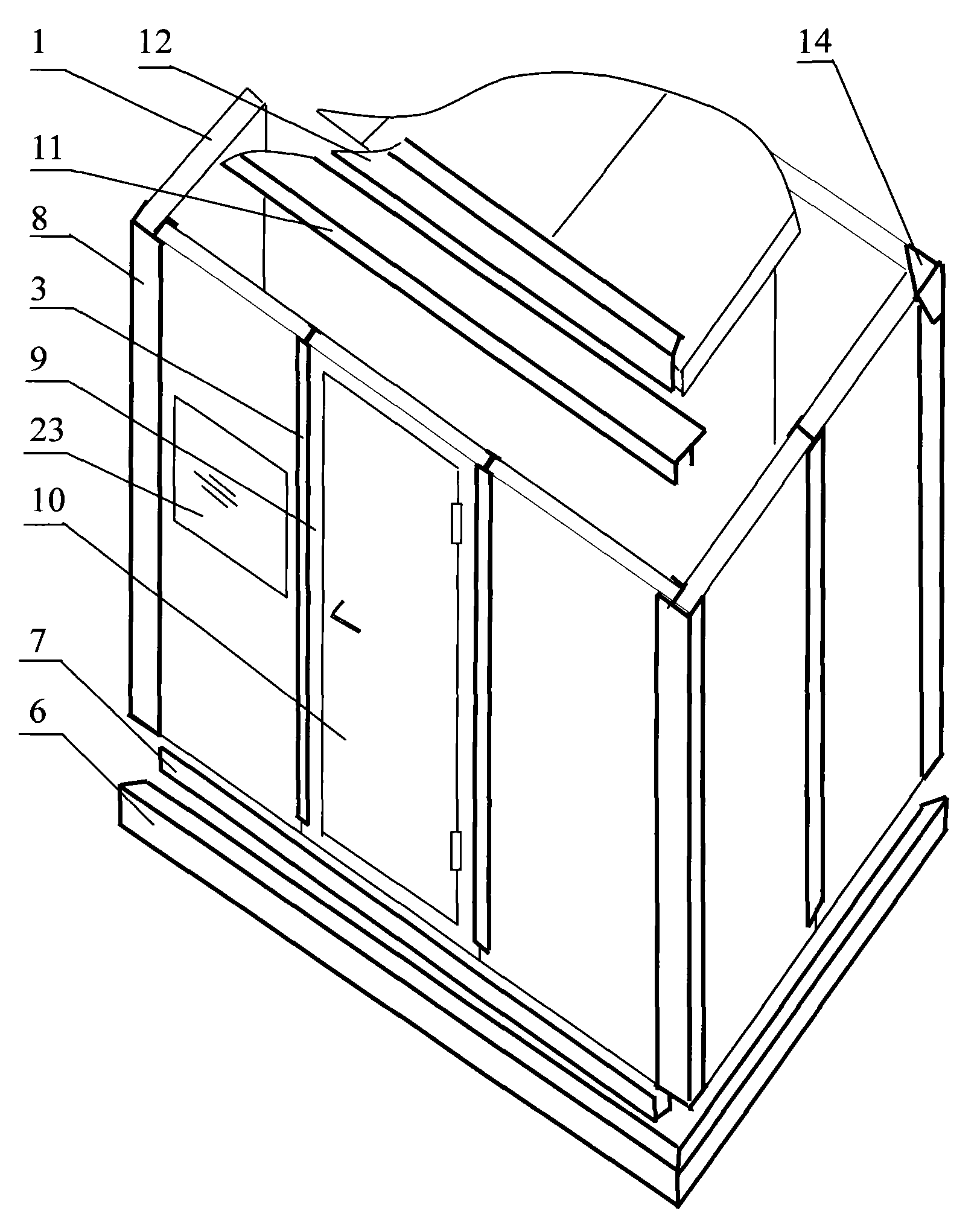

[0048] Such as figure 1 As shown, a voice recording studio used for radio and television, network education, university language teaching and research or rehabilitation training for deaf children, the size is 3m (length) * 2m (width) * 2.5m (height), install a 1m (width )*2m (height) 43 decibel soundproof door, a 800mm (width)*600mm (height) soundproof window, install ventilation and lighting system, require indoor and outdoor sound level difference to be 40dB(A).

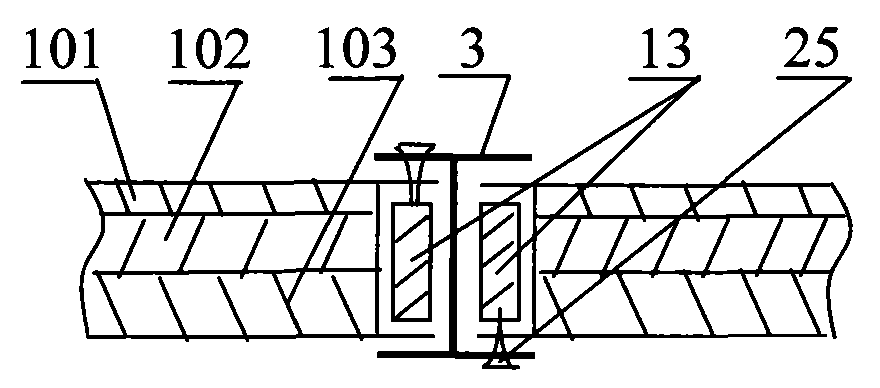

[0049] The bottom panel is composed of three sound insulation modules of 1m (width)*2m (length) connected sequentially through H-shaped steel connectors 3 . The metal plate is a 3mm thick steel plate, the sound insulation material is three layers of commercially available damping plates, the damping layer is commercially available damping glue, the sound absorption material layer is 50mm thick environmentally friendly glass wool, and the total thickness of the sound insulation module is 100mm. When the sound insul...

Embodiment 2

[0057] As shown in the figure, a two-station measurement room installed in an industrial plant for measuring motor noise, the size is 3m (length) * 2m (width) * 2.5m (height), and one installation is 1m (width)* 2m (height) 43 decibel sound insulation door, a 800mm (width) * 600mm (height) sound insulation window, install ventilation and lighting system, require indoor and outdoor sound level difference to be 50dB (A).

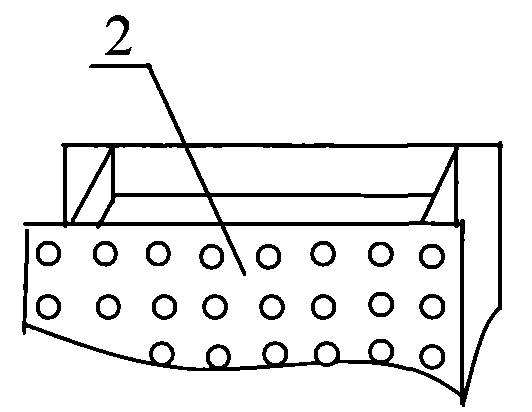

[0058] Due to the high environmental noise and mechanical vibration noise in the factory building, it is necessary to use a spring and flat rubber combination vibration isolator. The sound insulation-sound absorption module 2 is used for the facade panel and top panel of the sound insulation room, which has a sound insulation capacity of 45 decibels. The sound insulation room is placed in a corner of the workshop, two sides are against the wall, and the other two sides are separated by 300m, and an outer facade panel with two walls is installed. Each side is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com