Floor board with upper surface having lumber grain groove and color and manufacturing method thereof

A floor and wood technology, applied in the direction of chemical instruments and methods, manufacturing tools, wood layered products, etc., can solve the problems that the upper surface is too smooth, easy to slip, lack of three-dimensional effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

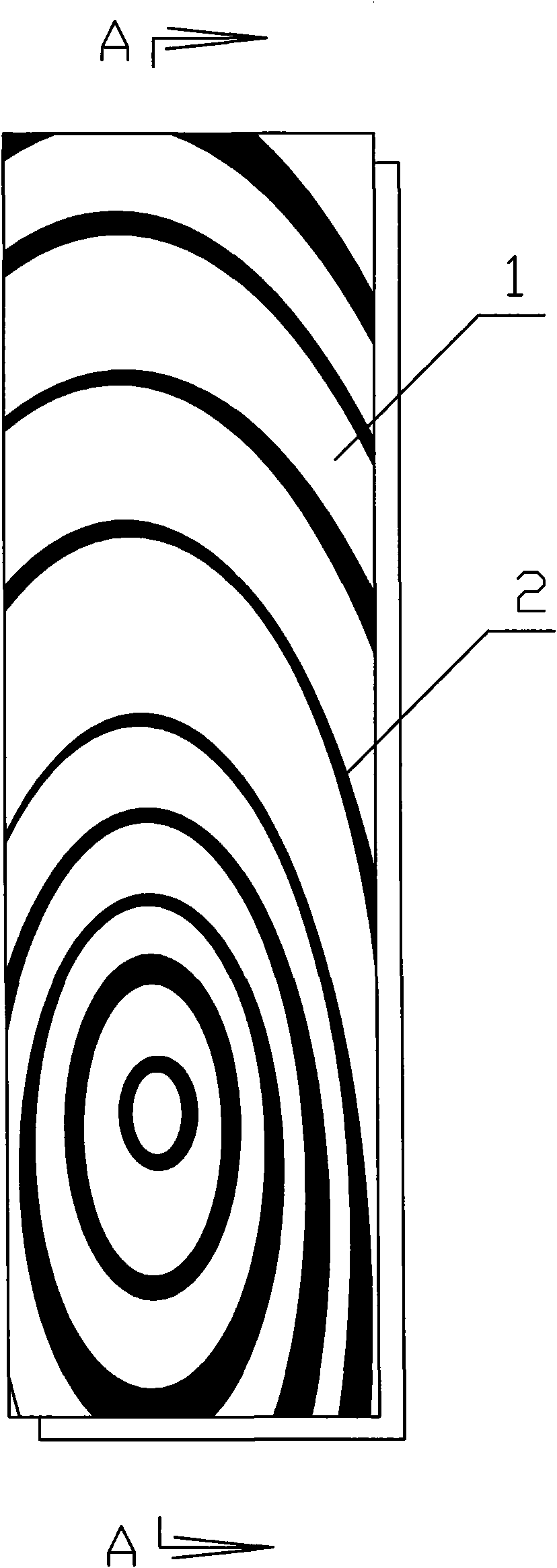

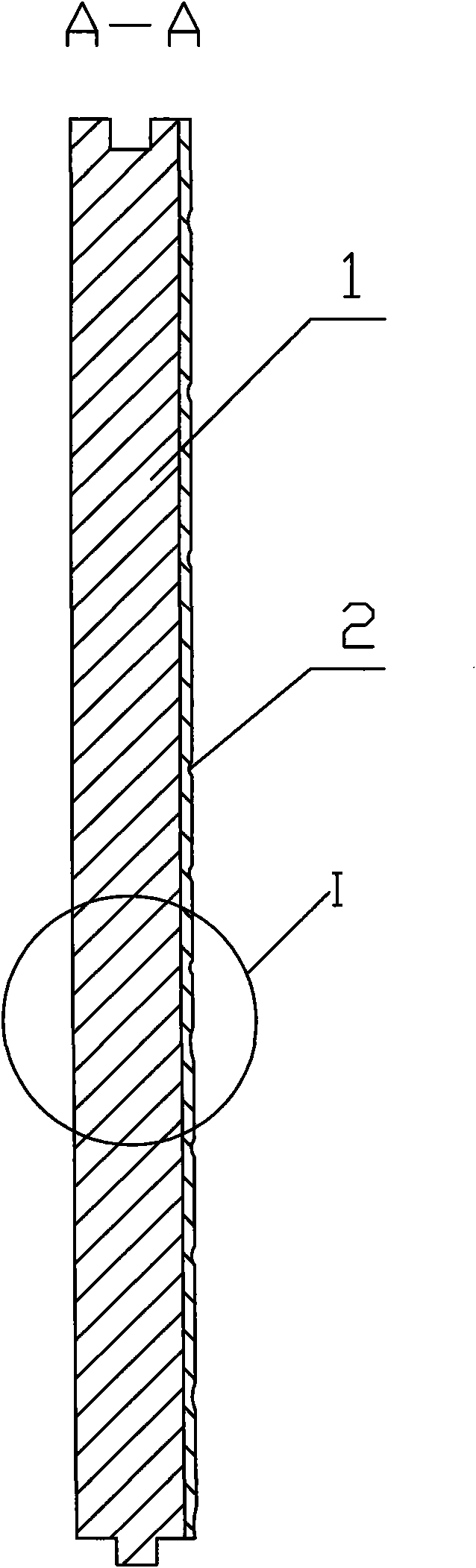

[0033] figure 1 , figure 2 , Figure 4 The floor shown has wood grain grooves and colors on the upper surface, including a floor body 1 formed by composite processing of the upper layer 6 and the lower layer 3, the upper surface of the floor body 1 has grooves 2 of wood grain, the Groove 2 has color.

no. 2 example

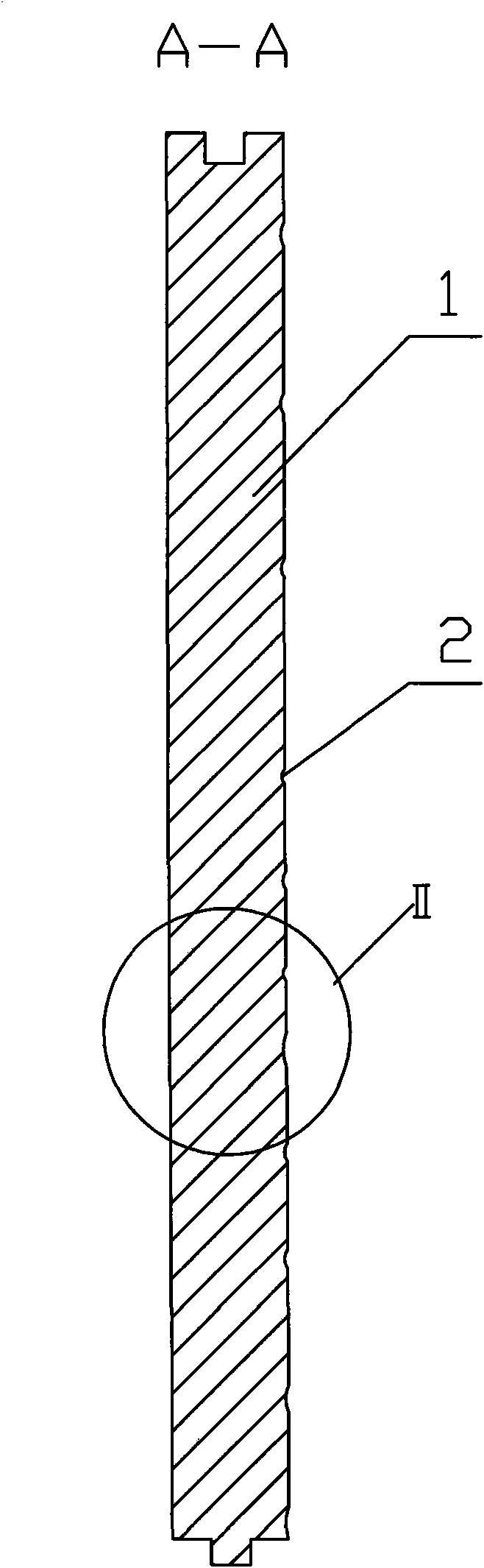

[0035] figure 1 , image 3 , Figure 5 The illustrated floor has wood grain grooves and colors on its upper surface, including a floor body 1 processed from wood. The upper surface of the floor body 1 has wood grain grooves 2, and the grooves 2 have colors.

[0036] The first method of manufacturing the floor with wood grain grooves and colors on the upper surface of the first embodiment is carried out according to the following steps:

[0037] ① wood rotary cutting or planing to process the upper layer 6;

[0038] ② Composite processing of the upper layer 6 and the lower layer 3 into the floor body 1;

[0039] ③ Brush the upper surface of the floor body 1 with a steel wire wheel, and brush the natural grain of the wood out of the groove 2;

[0040] ④ Spray the desired color on the upper surface of the floor body 1 and dry it;

[0041] ⑤ Remove the color sanding on the upper surface plane of the floor body 1;

[0042] ⑥ Spray a protective coating on the upper surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com