Doping method and method for forming LDD doped area

A technology of doping regions and point defects, which is applied in the field of doping methods and the formation of LDD doping regions, can solve the problems of deep junctions and achieve the effect of reducing junction depths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] With the continuous improvement of the semiconductor integrated circuit manufacturing process, the line width of the gate is getting smaller and smaller, and correspondingly, the junction depth of the doped region is also required to be shallower. The invention provides a doping method capable of forming a doped region with a shallower junction depth.

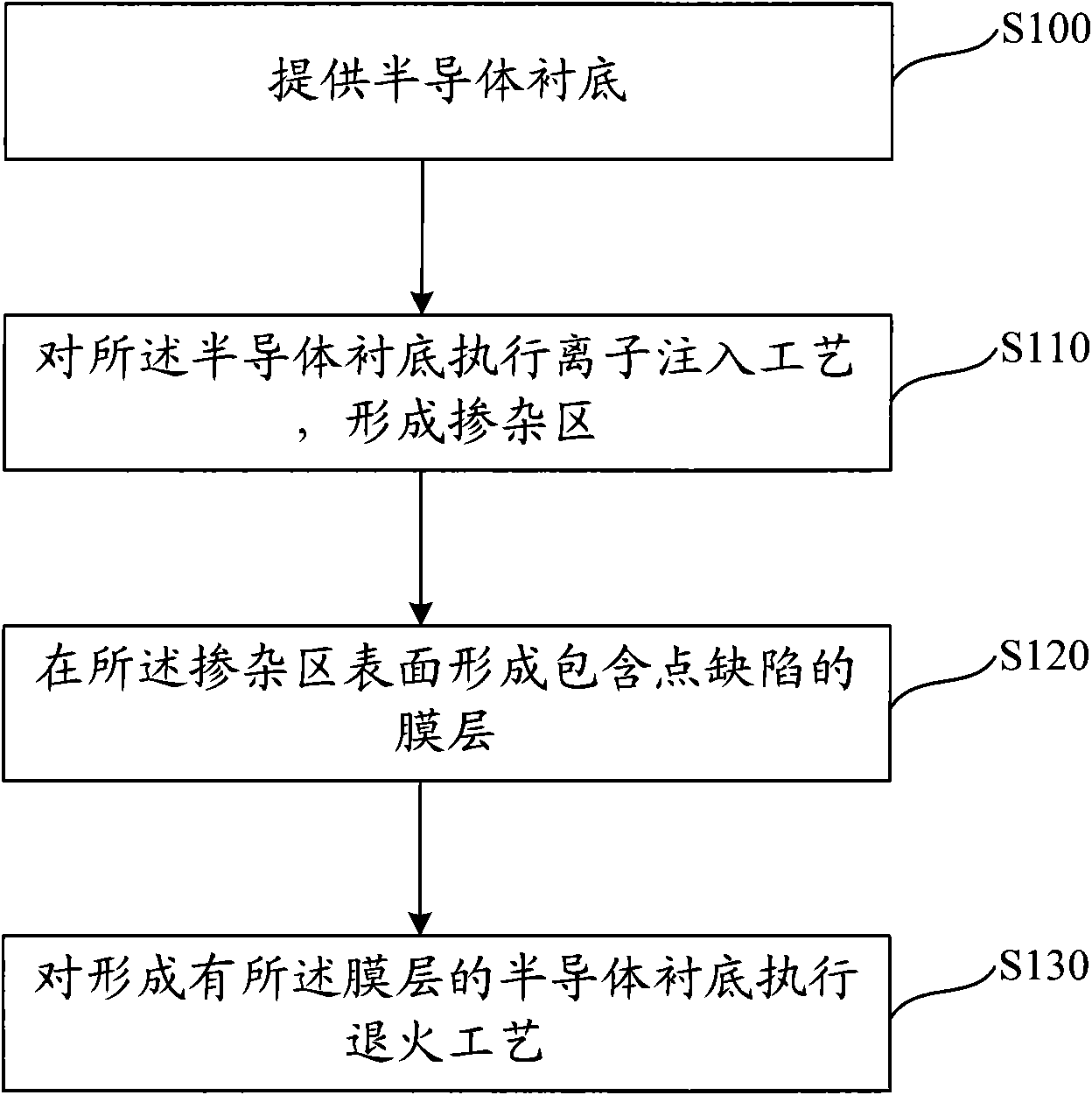

[0037] figure 1 It is a flowchart of an embodiment of the doping method of the present invention.

[0038] Please refer to figure 1 , step S100 is to provide a semiconductor substrate.

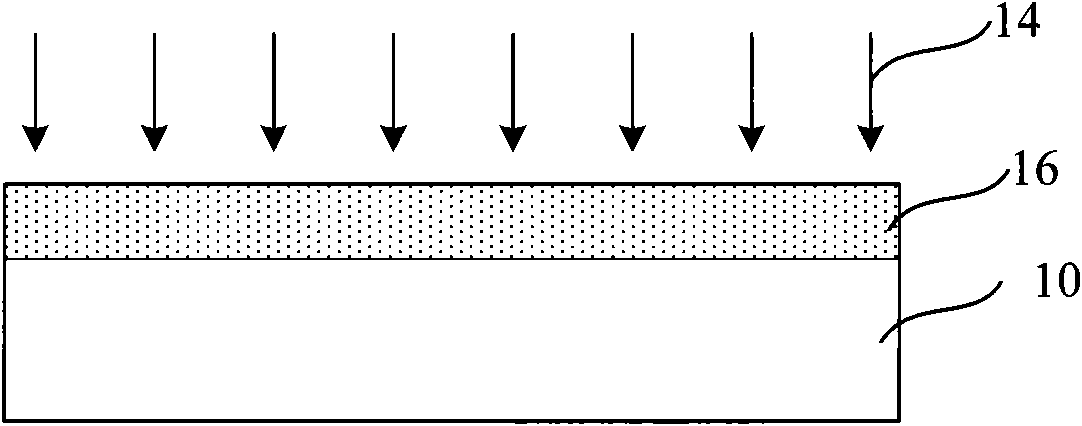

[0039] Step S110 is performing an ion implantation process on the semiconductor substrate to form a doped region.

[0040] Step S120 is forming a film layer containing point defects on the surface of the doped region.

[0041] Step S130 is performing an annealing process on the semiconductor sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com