Preparation method of PERC battery

A battery and power supply technology, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve the problems of low efficiency of PERC cells, low efficiency, poor passivation efficiency of passivation film, etc., and increase the polishing effect , improve the uniformity, improve the effect of passivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The terminology used herein is for the purpose of describing particular embodiments only and is not intended to be limiting of the invention. Unless otherwise defined, all terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. It will be further understood that commonly used terms should be interpreted to have a meaning consistent with their meaning in the relevant art and this disclosure. This disclosure is to be considered as an example of the invention and is not intended to limit the invention to the particular embodiments.

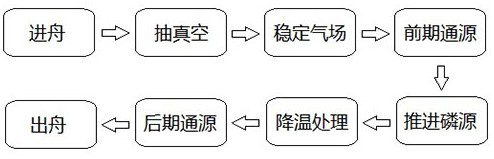

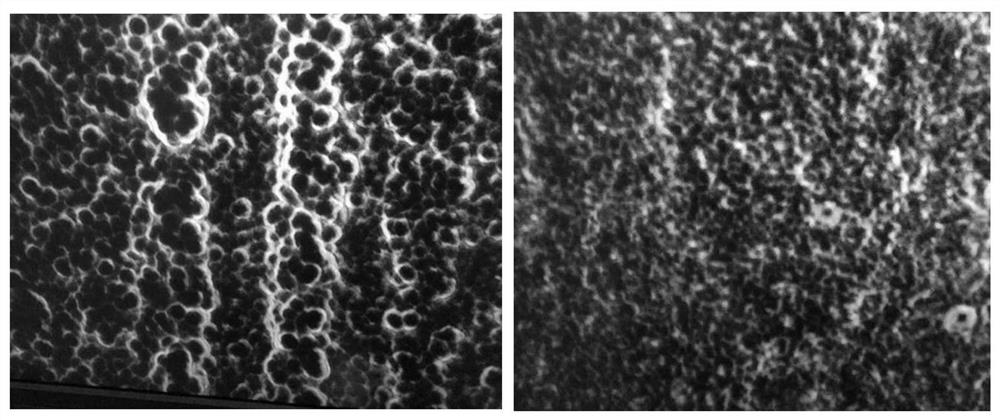

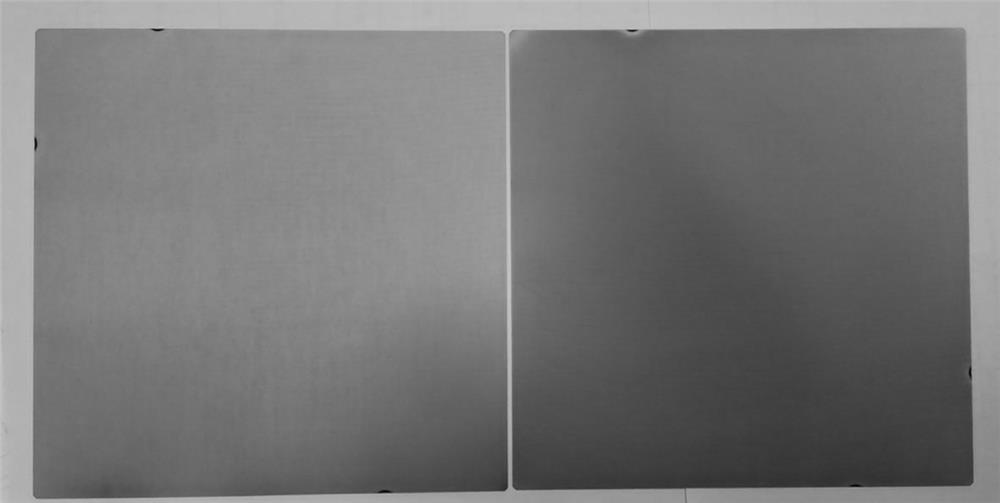

[0028] This embodiment provides a method for preparing a PERC battery, which is mainly used to improve the efficiency of the PERC battery. The method comprises: successively a diffusion step, an etching step, and a back film step, wherein an etching solution is used in the etching step, and the chemical composition of the etching solution includes HNO 3 , HF, H 2 SO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com