Non-aqueous electrolyte secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in non-aqueous electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems of reducing battery rate characteristics, reducing battery rate characteristics, hindering lithium ion conduction, etc., and achieving rate characteristics The effect of less decrease in the amount and excellent preservation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

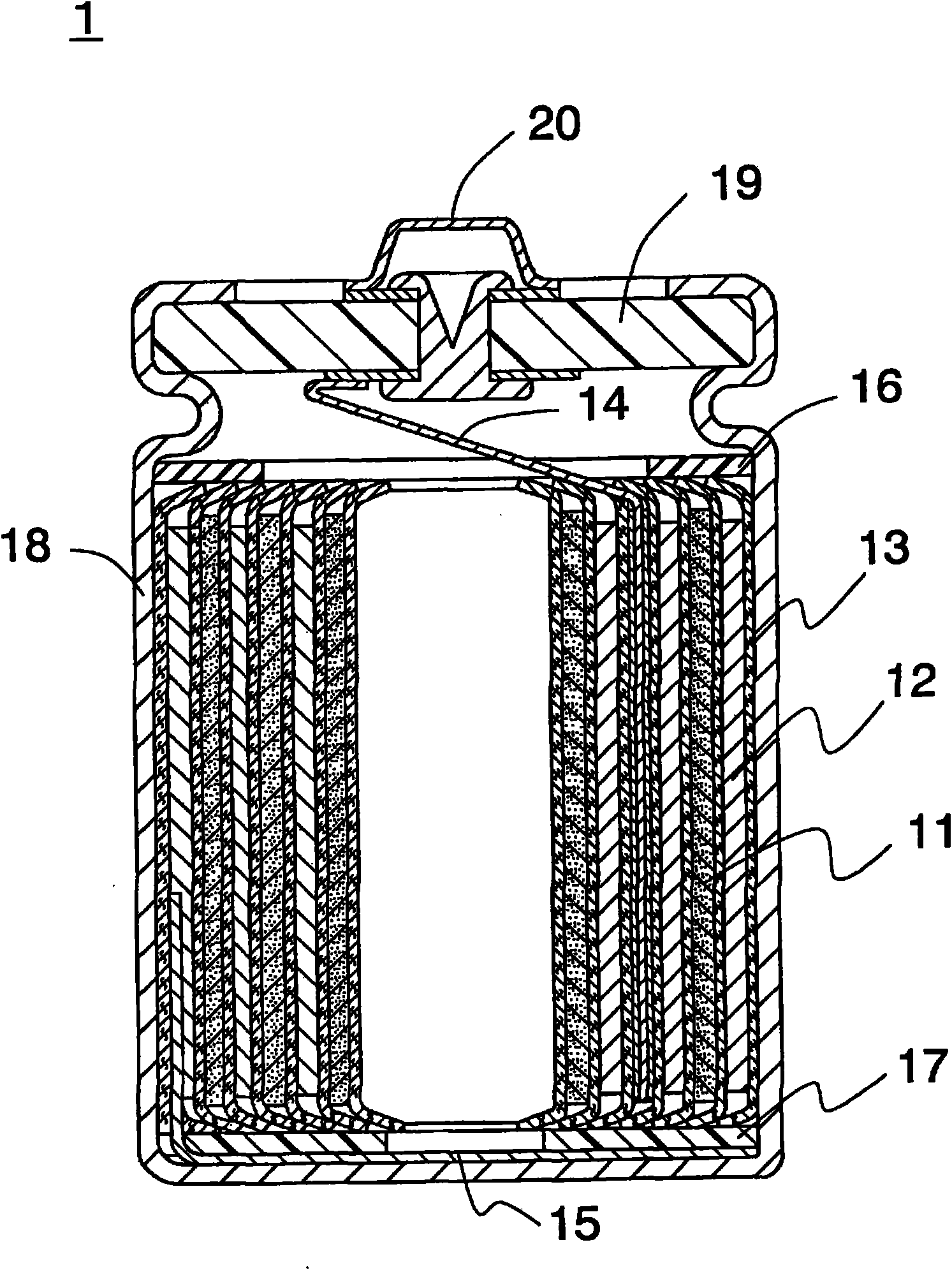

Image

Examples

Embodiment 1

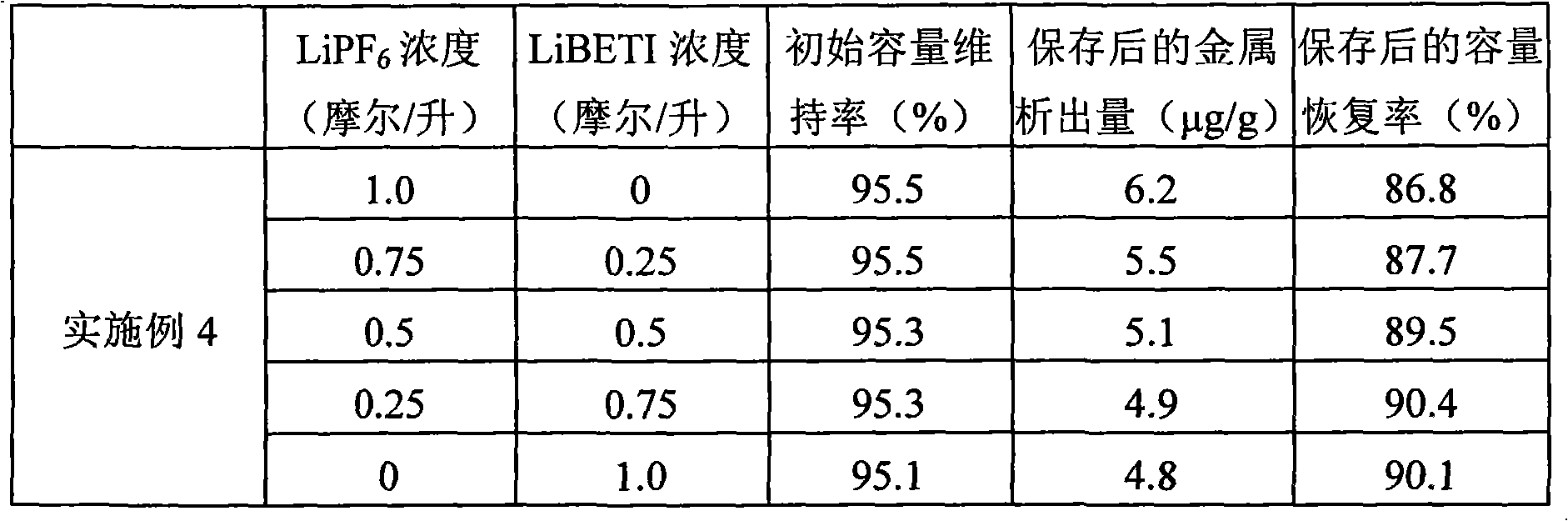

[0088] (1) Preparation of non-aqueous electrolyte

[0089] Dissolving LiPF in sulfolane 6 , to a concentration of 1 mol / L. To the obtained solution, 1,3-propane sultone (hereinafter abbreviated as "PRS") was added in a ratio of 2 parts by weight to 100 parts by weight of sulfolane to prepare a nonaqueous electrolyte.

[0090] (2) Diaphragm

[0091] As the separator, a polyethylene microporous sheet (manufactured by Asahi Kasei Chemical Co., Ltd.) with a thickness of 20 μm was used.

[0092] (3) Production of positive electrode

[0093] Mix 85 parts by weight of lithium cobalt oxide powder (positive electrode active material, the median particle size based on volume is 10 μm, produced by Tanaka Chemical Research Institute), 10 parts by weight of acetylene black (conductive agent, Electrochemical Industry Co., Ltd. Production), 5 parts by weight of polyvinylidene fluoride resin (binder, produced by Kureha) and 40 parts by weight of dehydrated N-methyl-2-pyrrolidone (NMP, dis...

Embodiment 2

[0111] Not at the positive electrode, but on the surface of the negative electrode active material layer on both sides of the negative electrode, a porous film containing an inorganic oxide is formed, except that, in the same manner as in Example 1, a cylindrical nonaqueous electrolyte secondary electrode of the present invention is produced. battery and was evaluated. The results are shown in Table 1.

Embodiment 3

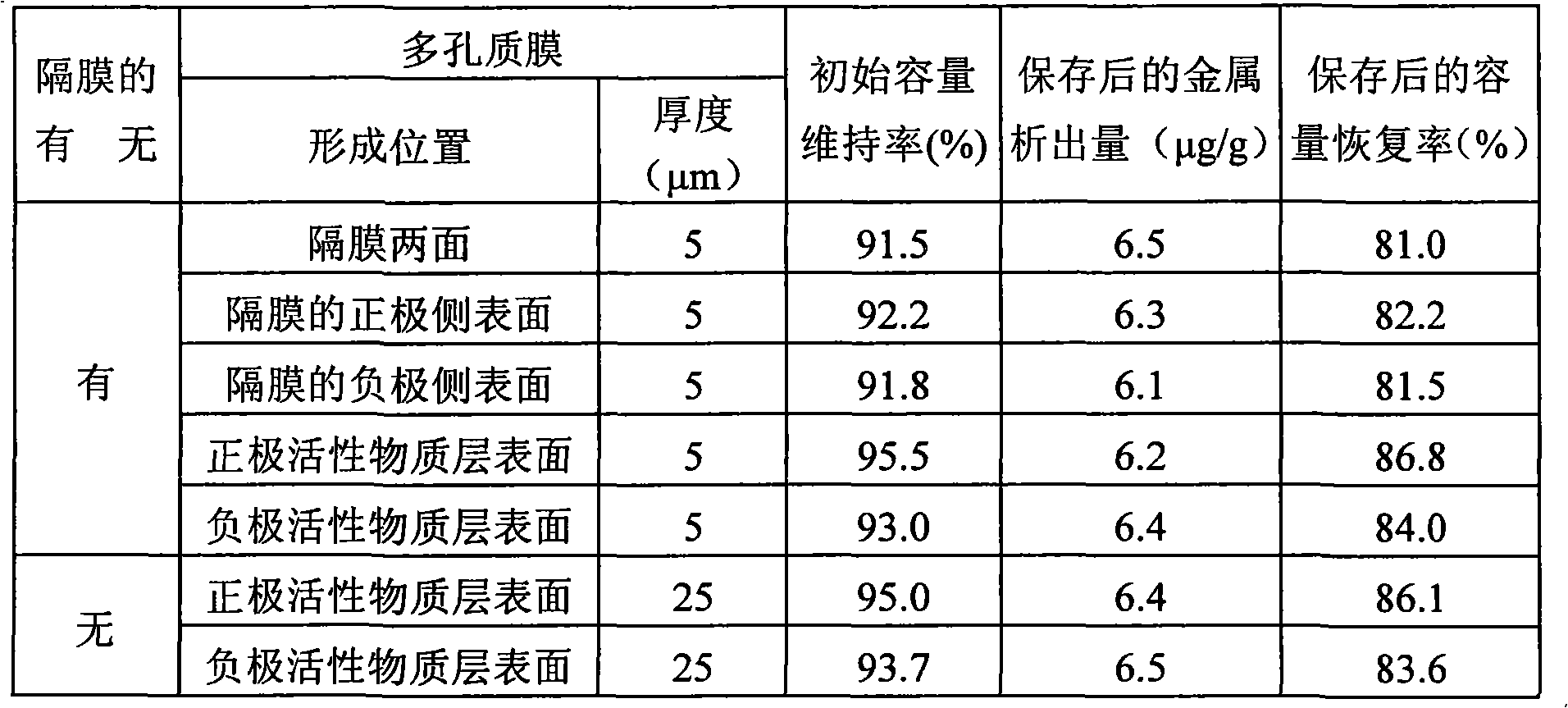

[0127] As shown in Table 2, except that the presence or absence of the separator, the formation position of the porous film containing the inorganic oxide, and the film thickness of the porous film were changed, the cylindrical non-conductive film of the present invention was produced in the same manner as in Example 1. Aqueous electrolyte secondary batteries were evaluated. The results are shown in Table 2 together.

[0128]In addition, in this embodiment, the positive electrode active material layer and the negative electrode active material layer are respectively formed on both surfaces in the thickness direction of the positive electrode and the negative electrode. Therefore, in the item "Position of Porous Membrane" in Table 2, for example, "surface of positive electrode active material layer" means that porous membranes are formed on both surfaces of the positive electrode. In addition, in the "Position of Porous Membrane" and "Thickness of Porous Membrane" in Table 2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com