High-density elastic weft-knitting fleece fabric and manufacturing method thereof

A manufacturing method and technology of weft knitting, applied in the directions of weft knitting, knitting, textile and paper making, etc., to achieve the effect of full suede, soft hand feeling, high elasticity and extensibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

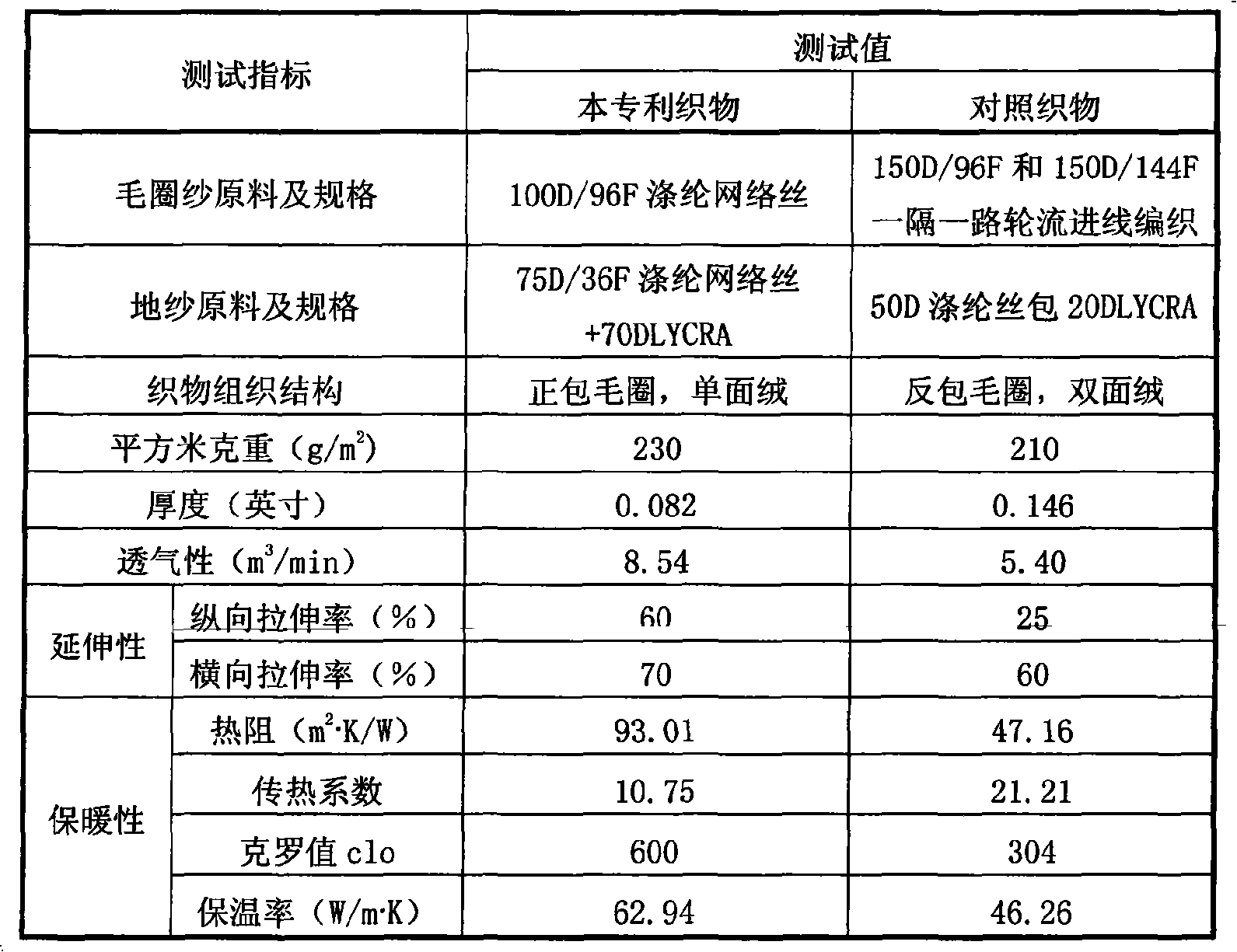

Embodiment 1

[0017] A high-density elastic weft-knitted fleece fabric, using spandex bare silk and polyester network yarn to weave the terry fabric through single-sided weft-knitted terry weaving, and then pulling the elongated settlement arc of the terry structure of the terry fabric Process made. Wherein the ground yarn in the terry gray cloth is 70D spandex bare silk and 100D / 96F polyester network silk double-ply incoming thread. The terry yarn in the terry gray cloth is 75D / 36F polyester network yarn, and the network points of the polyester network yarn are 110-130 pieces / m.

Embodiment 2

[0019] A method for manufacturing a high-density elastic weft-knitted fleece fabric, which includes a weaving step and a napping step in sequence, and the weaving step includes weaving spandex bare yarn and polyester network yarn through a single-sided weft-knitted terry weave into a full-covered terry gray fabric, The napping step includes making the elongated sinker arc of the terry structure into a single-face fleece fabric through a napping treatment process, wherein the ground yarn is 70D spandex bare silk and 100D / 96F polyester network yarn double-ply incoming thread, and the terry yarn is 75D / 36F polyester network yarn, the network point of polyester network yarn is 110-130 / m.

[0020] Wherein, the weaving step specifically includes the following technological process in sequence: yarn preparation, weft knitting, knitting of seams, pretreatment, dehydration, width opening, dyeing presetting, dyeing, dehydration out of cylinders, and drying.

[0021] Wherein, the napping...

specific example

[0024] Use 70D spandex bare yarn and 100D / 96F polyester network yarn with 120 points / m network points as the ground yarn, and 75D / 36F polyester network yarn with 120 points / m network point as the terry yarn. Terry fabric is knitted on a terry machine. The technological setting of the movement track of the terry sinker is as follows: the triangle of the terry sinker is adjusted so that the foot point of the terry sinker in the knitting process is 9.5mm away from the outer diameter of the needle cylinder.

[0025] Fabric pretreatment process, dispersing chelating agent: 0.5-1g / l, strong degreasing agent: 3g / l, soda ash: 1-2g / l, treatment temperature: 95°C, time: 60 minutes, liquor ratio: 1:15.

[0026] Fabric dyeing presetting process, treatment temperature: 190°C, time: 45 minutes, overfeed 12%.

[0027] Fabric dyeing process, using disperse dyes, liquor ratio: 1:10-15, dispersing chelating agent: 0.3-0.5g / l, acetic acid: 0.4g / l, sodium acetate: 0.5g / l, leveling agent: 0.5-1.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com