Stainless steel wire for spaceflight

A technology of stainless steel and steel wire rope, applied in the field of metal products, to achieve the effect of large bearing capacity, high bending fatigue resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

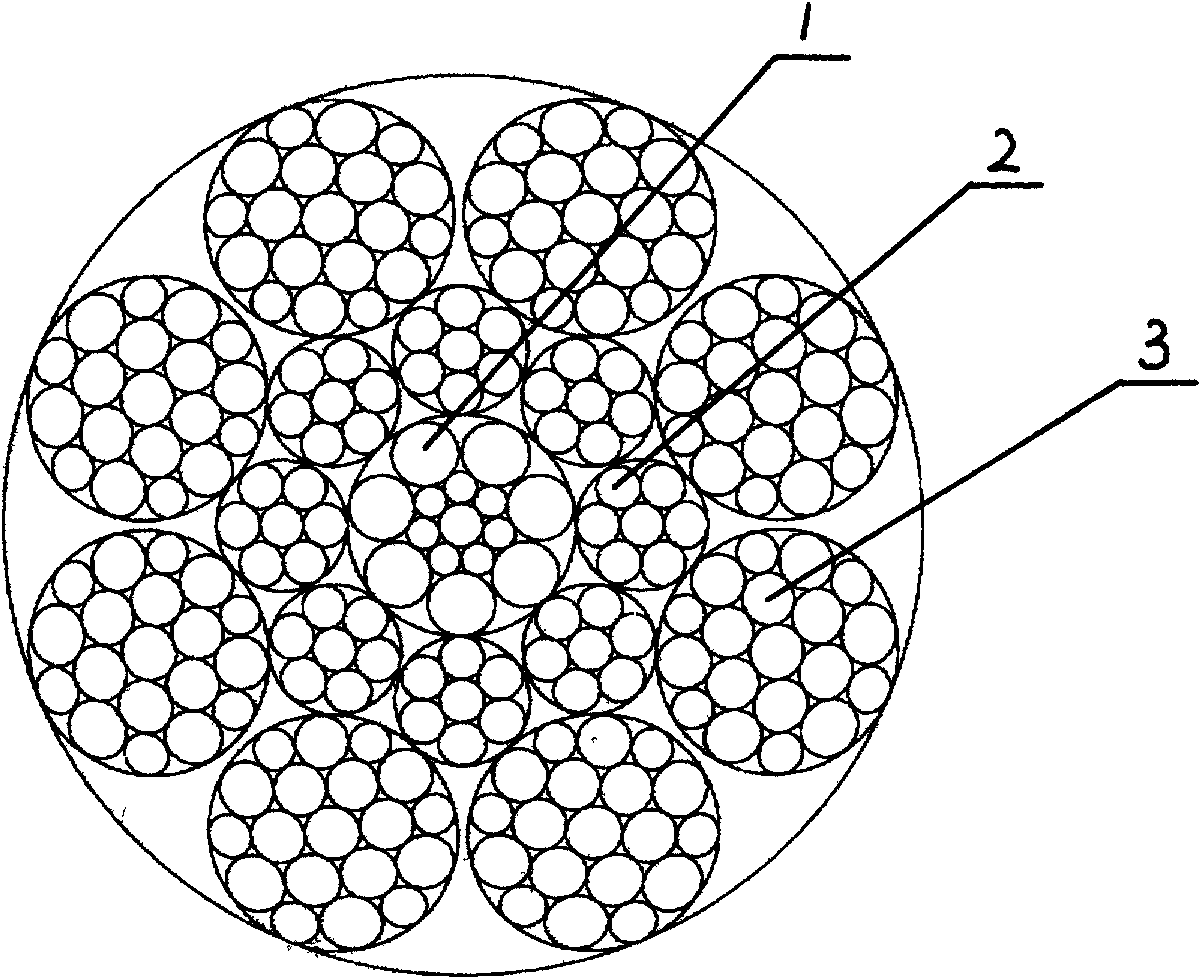

[0018] Embodiment: Stainless steel wire rope with CFRC8×19W structure, diameter 5.5mm, tensile strength 2160MPa, tempering in a continuous tempering furnace with hydrogen as protective gas, tempering temperature is 600~700°C; tempering time is 150~ 260 seconds, stainless steel wire rope for double-rope pull test (steel rope bypasses φ29mm pulley, pulley-to-rope ratio is 5.27:1), the breaking force of the whole rope is greater than 45KN, the breaking force of a single rope is greater than 26kN, and the steel wire rope is tempered. The bearing capacity is greatly improved, and its bearing capacity is 30-35% higher than that of ordinary aerospace steel wire ropes of the same specification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com