Single redundant bit digital correction method used for assembly line A/D converter

A digital correction and converter technology, applied in the direction of analog/digital conversion, analog-to-digital converter, code conversion, etc., can solve the problems of layout area, power consumption input and output delay time increase, etc., to reduce the total number of stages, reduce The effect of the series

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention are not limited to the following description, and are now further described in conjunction with the accompanying drawings.

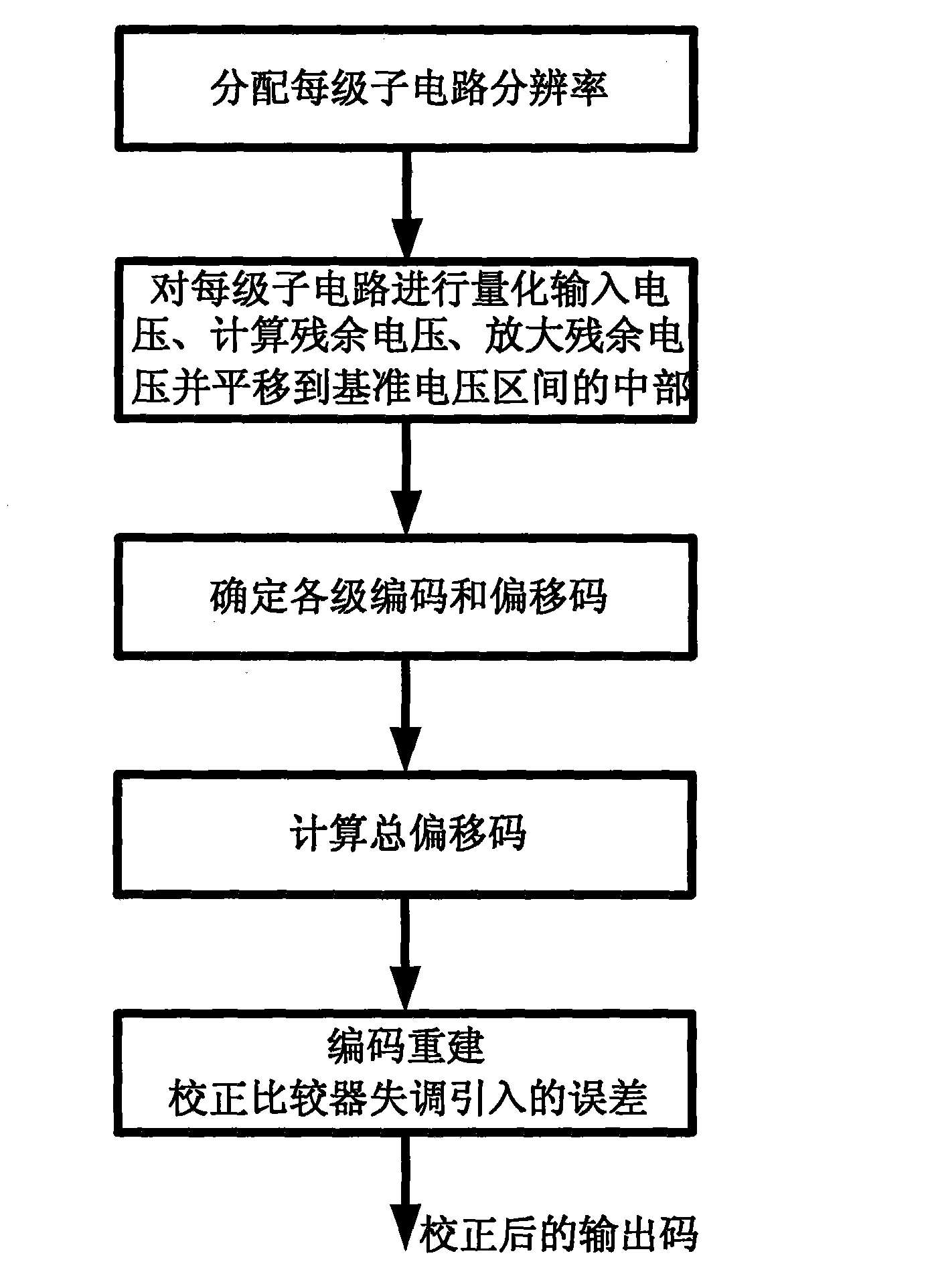

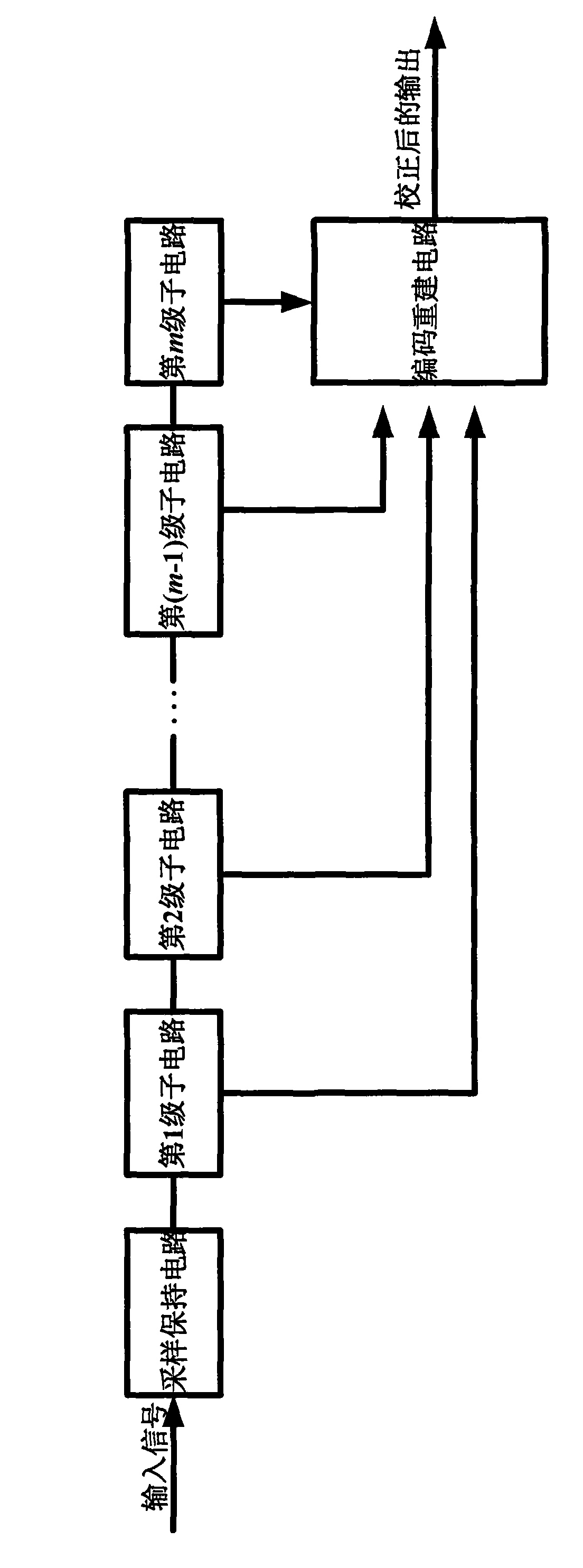

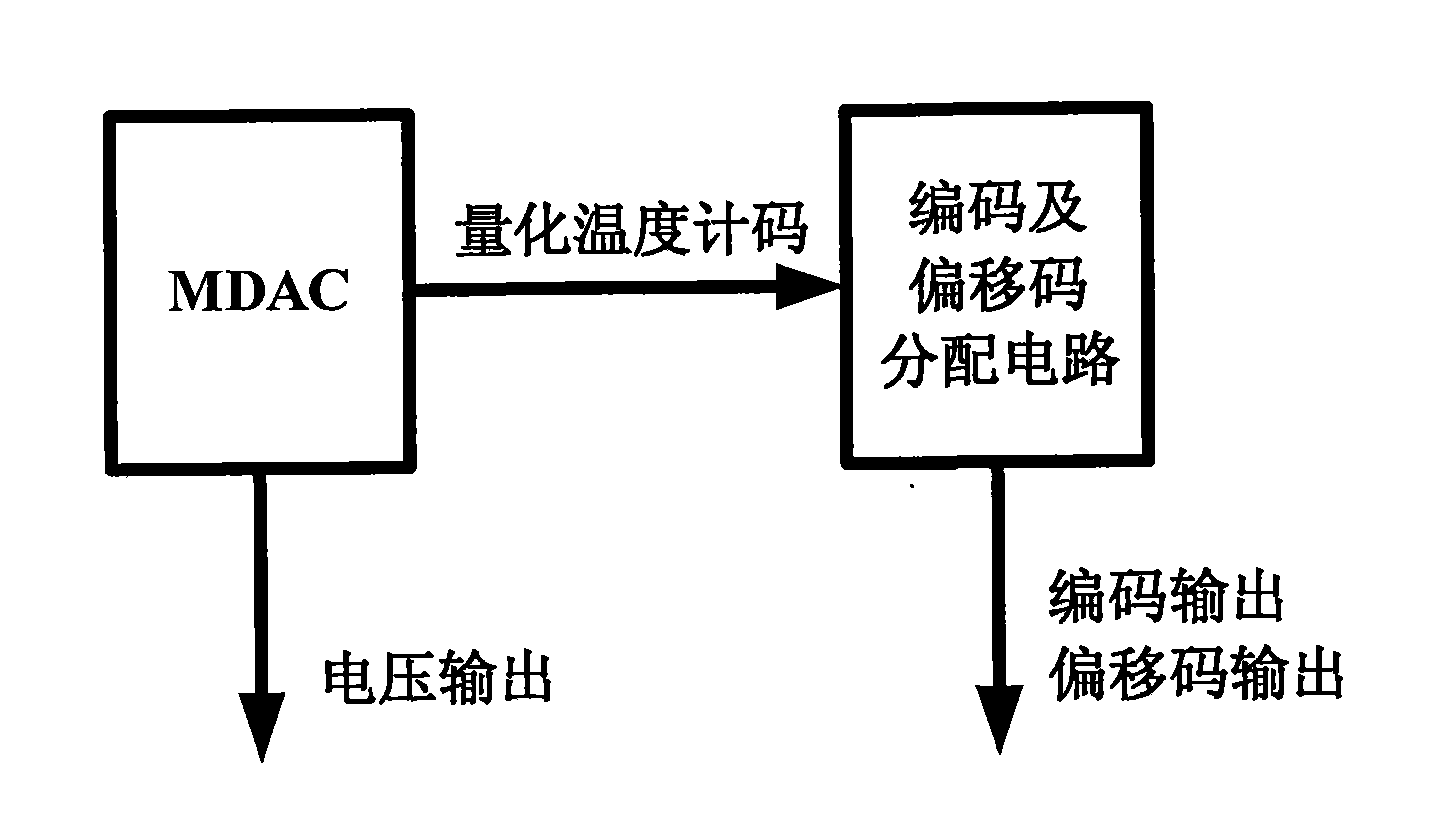

[0038] The overall structure schematic diagram of pipeline A / D converter in the inventive method is as figure 2 shown. The structure of the entire pipeline A / D converter includes a sample-and-hold circuit, m sub-circuits and a code reconstruction circuit. Its working principle is: the external input signal is sent to the first-level sub-circuit through the sample-and-hold circuit, and the first-level The sub-circuit quantifies its input voltage to obtain the quantized thermometer code, and calculates the analog voltage corresponding to the quantized thermometer code, that is, obtains the quantized voltage, then subtracts the quantized voltage from the input voltage to obtain the residual voltage, and amplifies the residual voltage and shift to the middle of the reference voltage interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com