Automatic calibration method for CT projection center

An automatic correction and projection center technology, applied in photography, optics, instruments, etc., can solve the problems of increasing the number of scans and measurement time, consuming the life of ray sources and detectors, and cumbersome problems, so as to save measurement time and prolong the effective working life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

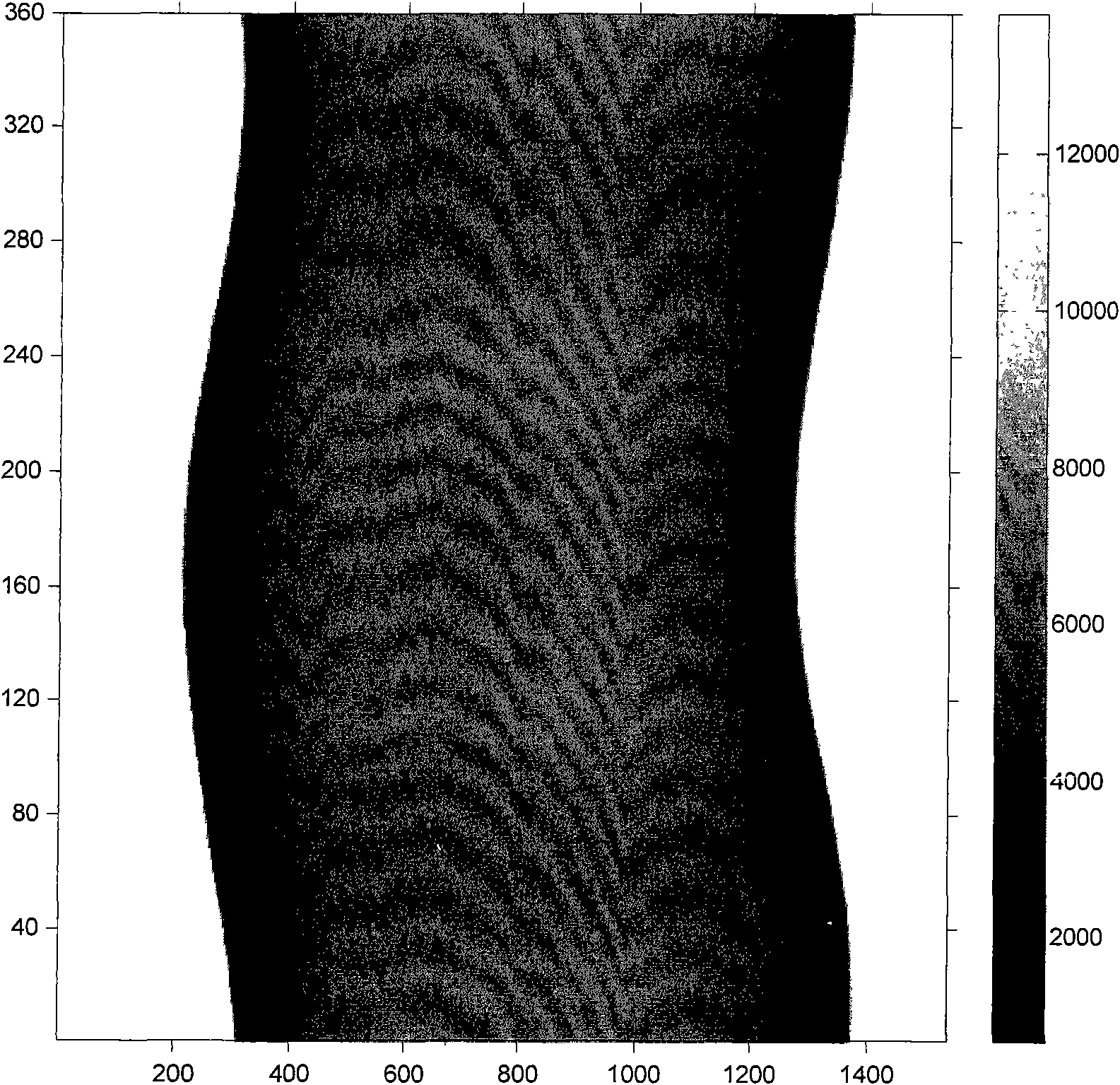

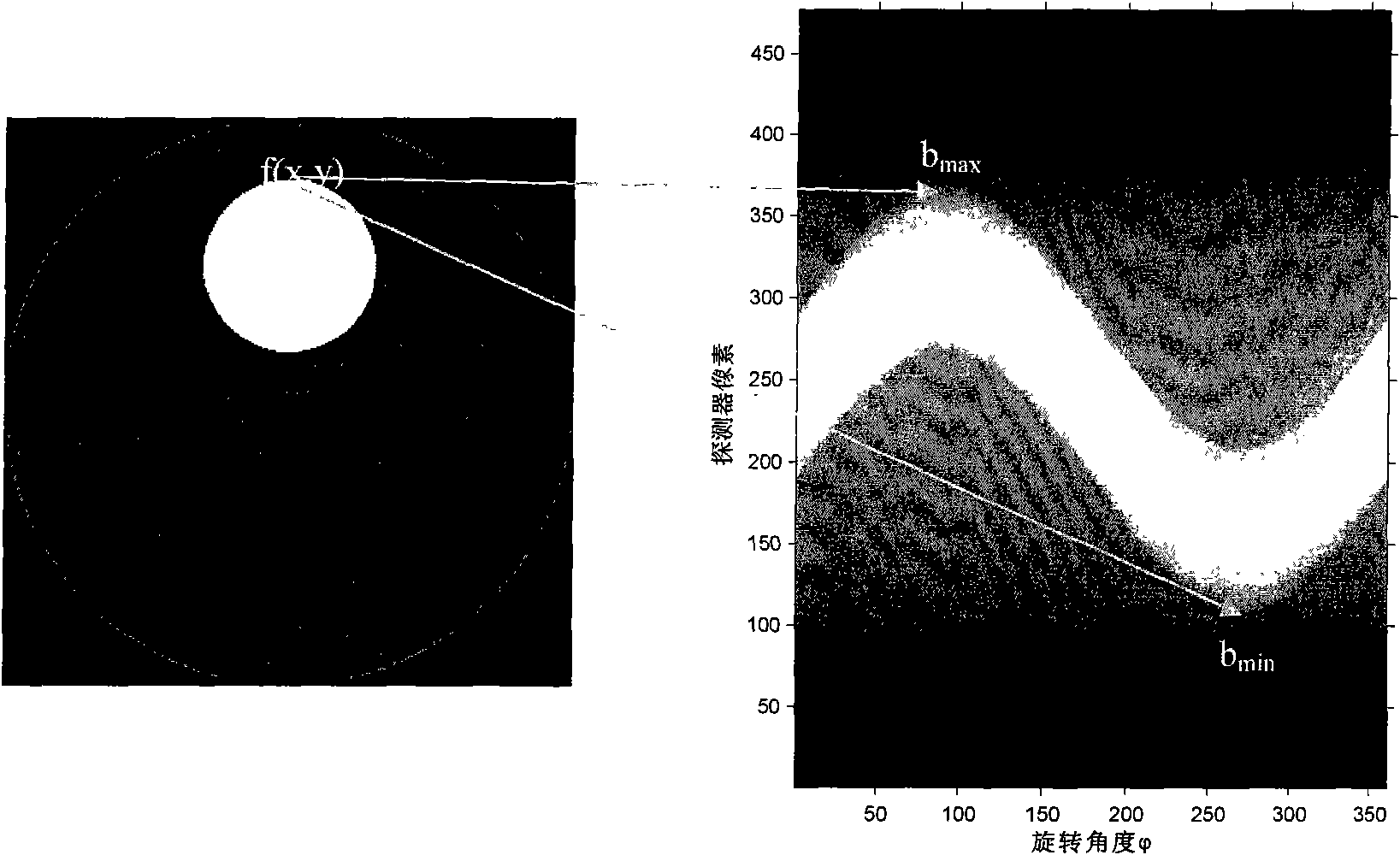

[0034] The present invention can be used in various CT non-destructive testing fields. The technical details of the present invention will be described below by taking the detection of cross-sectional material distribution in a circulating fluidized bed reactor as an example.

[0035] Circulating fluidized bed reactors are widely used in petroleum smelting, boilers, metallurgy and other fields. The cross-sectional material distribution in the reactor is an important indicator of the operating status of the reactor. CT can measure the cross-sectional view of the reactor material distribution without interference , has aroused great interest in the industry in recent years. This implementation example is to apply CT to the inlet section of the riser of the circulating fluidized bed for measurement.

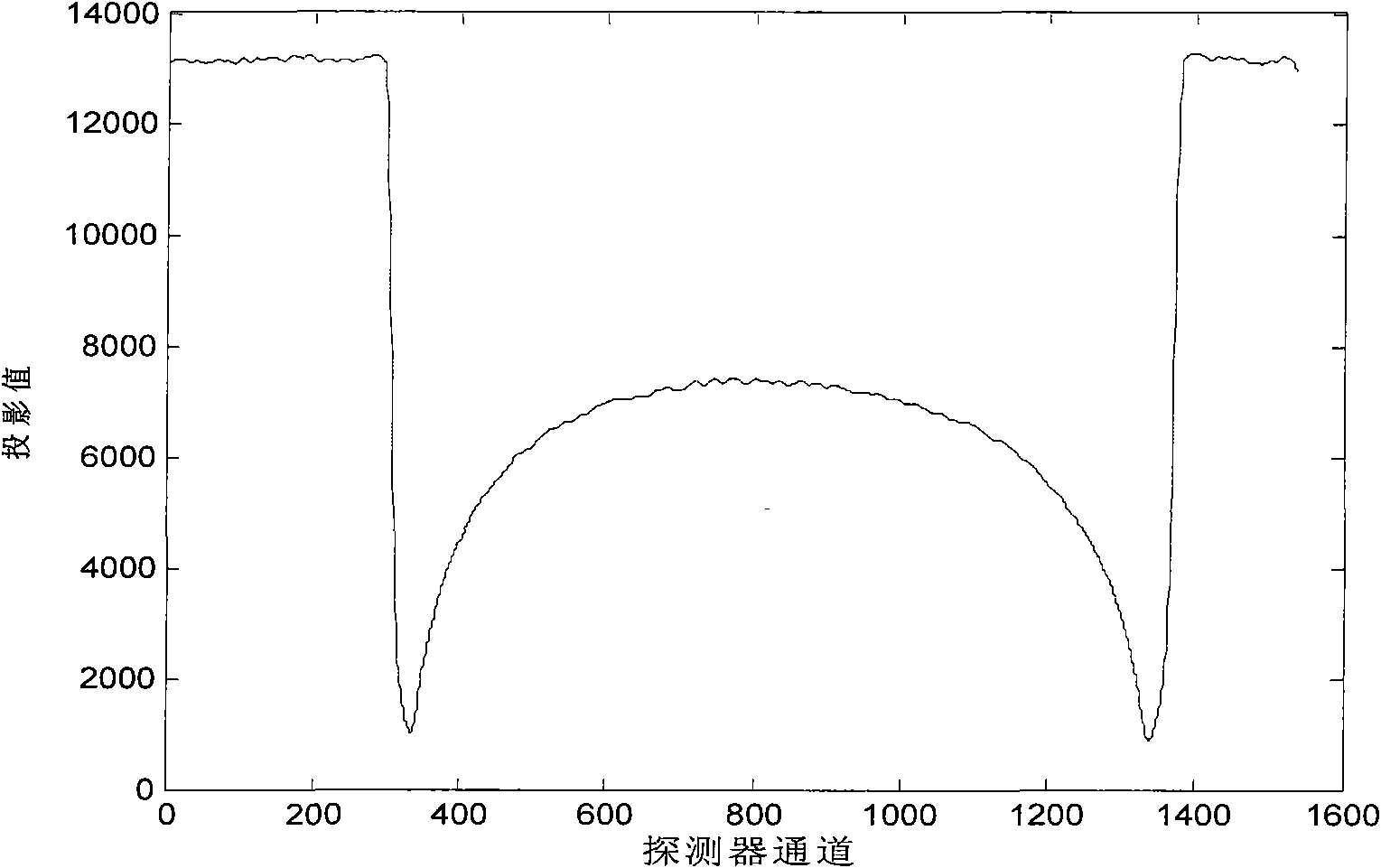

[0036] The CT machine used in this implementation example belongs to the third-generation X-ray CT, and the detectors are arranged in an equidistant linear array, with a total of 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com