Method for manufacturing antibacterial acrylon by adopting blending addition modifying method

A modified acrylic fiber technology, which is applied in the manufacture of rayon, wet spinning, textiles and papermaking, etc., can solve the problems of poor compatibility between antibacterial agents and spinning dope, and achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

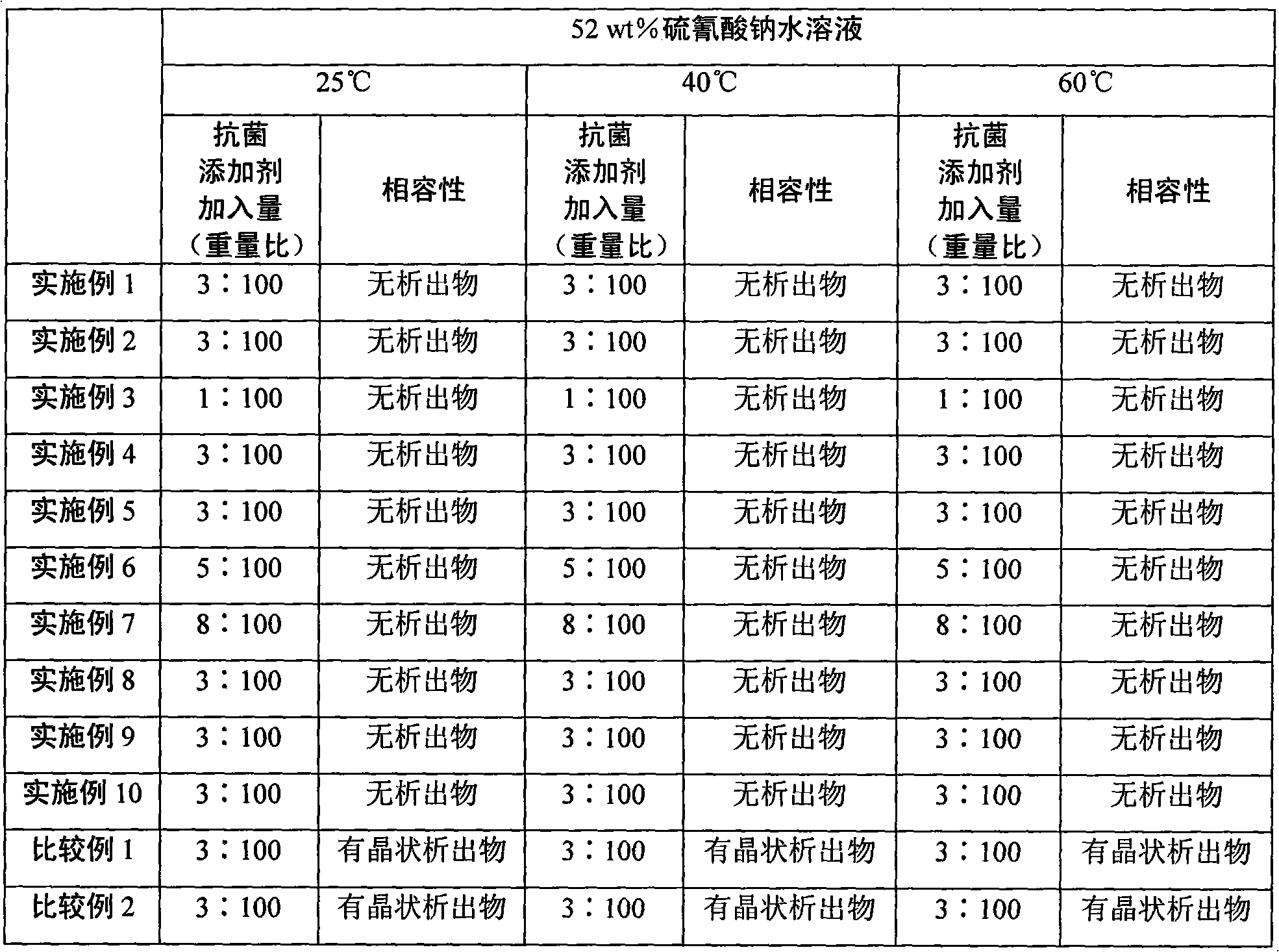

Embodiment 1~10

[0021] At 70°C, uniformly mix the solubilizer and emulsifier with the solvent polyethylene glycol-400 in the required ratio, then gradually add the required amount of antibacterial agent into it under stirring, and continue to stir until the system It was clear and transparent, and cooled to prepare an antibacterial additive for later use.

Embodiment 11~18

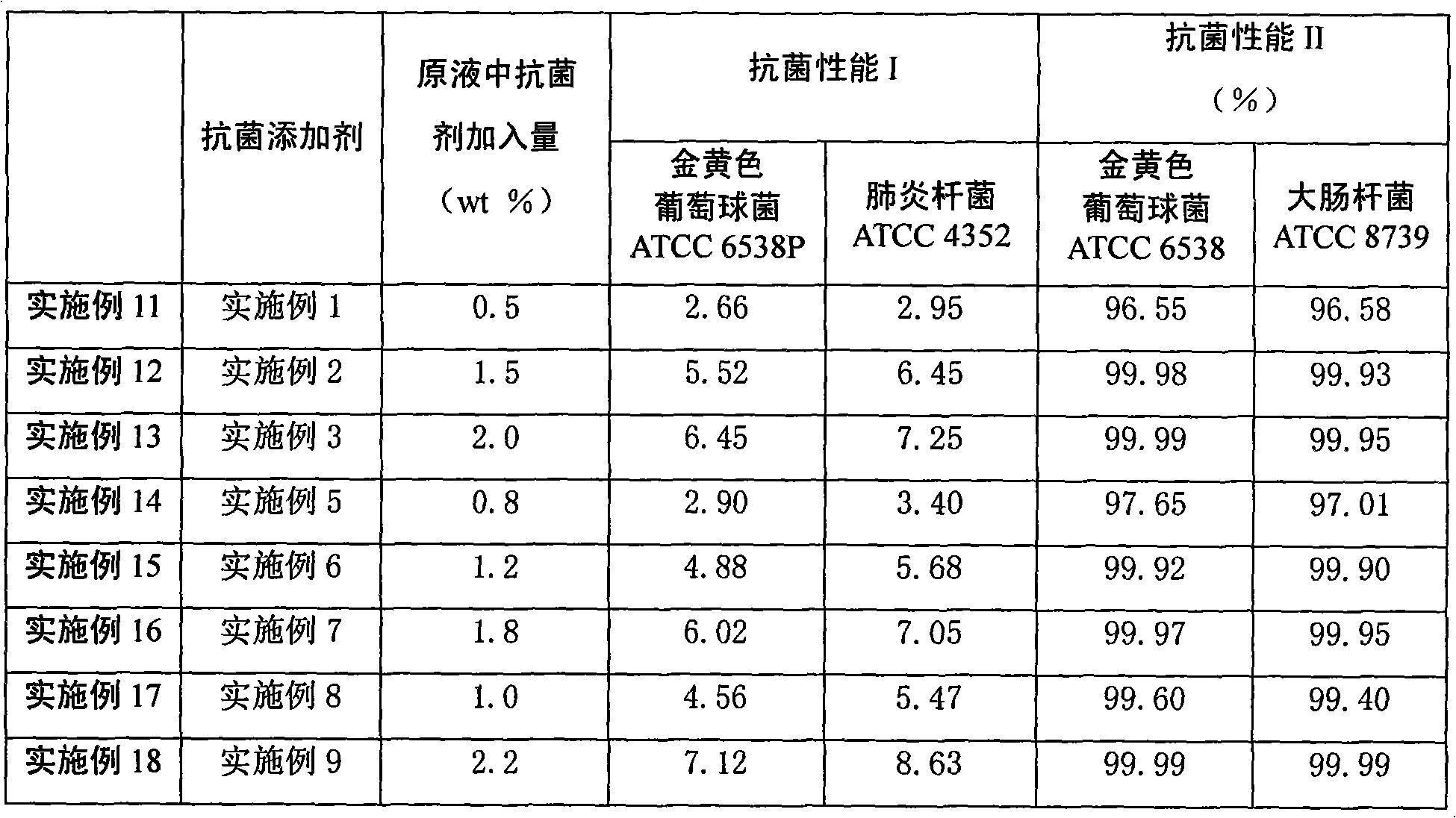

[0041] The antibacterial additive is added to the acrylic fiber spinning stock solution (the total solid content of stock solution is 12wt%) with sodium thiocyanate aqueous solution (concentration is 51.3wt%) as spinning solvent by online injection equipment, spinning stock solution is passed through a static mixing device to mix the antibacterial additive with the original solution evenly. Carry out spinning and post-processing according to the general wet spinning process conditions (post-processing steps include cold drawing, washing, hot drawing, oiling, drying and densification, crimping and heat setting, etc.), and the obtained fineness is 1.67dtex antibacterial acrylic. During the whole spinning process, the pressure of the nozzle assembly and the filter did not change abnormally, and the spinning process was smooth.

[0042] See Table 4 for the amount of antibacterial agent added to the spinning dope and the results of the antibacterial test in Examples 11-18. Antiba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com