Floating night lock core and a lock core service system

A technology of pin lock cylinder and lock core, which is applied to cylinder pin locks, locks with turning keys, building locks, etc., and can solve problems such as providing effective services for customers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

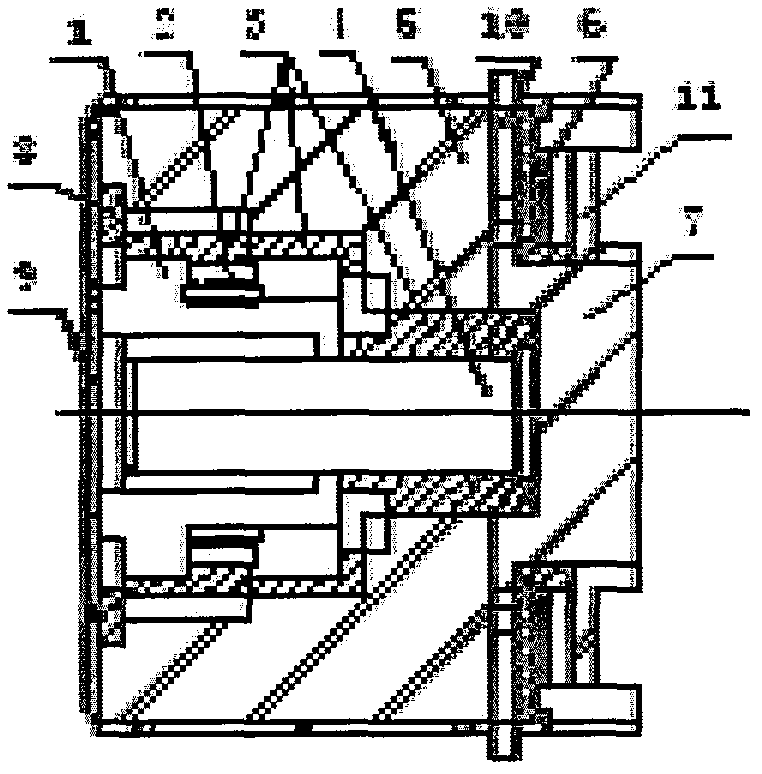

[0019] Example 1. As figure 1 Shown: The circular steel pipe gear lock cylinder is composed of floating pin cylinder assembly, quick-installed lock block, gear and other parts. The groove is connected with the drive end of the fast-loading lock block in a convex arc shape, and the small end is connected with the gear; the fast-loading lock block is a parallel body whose middle section is larger than the two ends, and the convex arc shape of the drive end corresponds to the groove on the outer diameter of the torque column. The convex shape of the locking end corresponds to the locking opening of the lock shell and the lock seat; the lock shell is provided with a through hole corresponding to the convex shape of the fast locking block locking end and the locking hole of the lock seat, and the shell mouth is provided with a gear and The connecting section of the rack corresponds to the corresponding opening; the position of the groove on the outer diameter of the torsion column ...

Embodiment 2

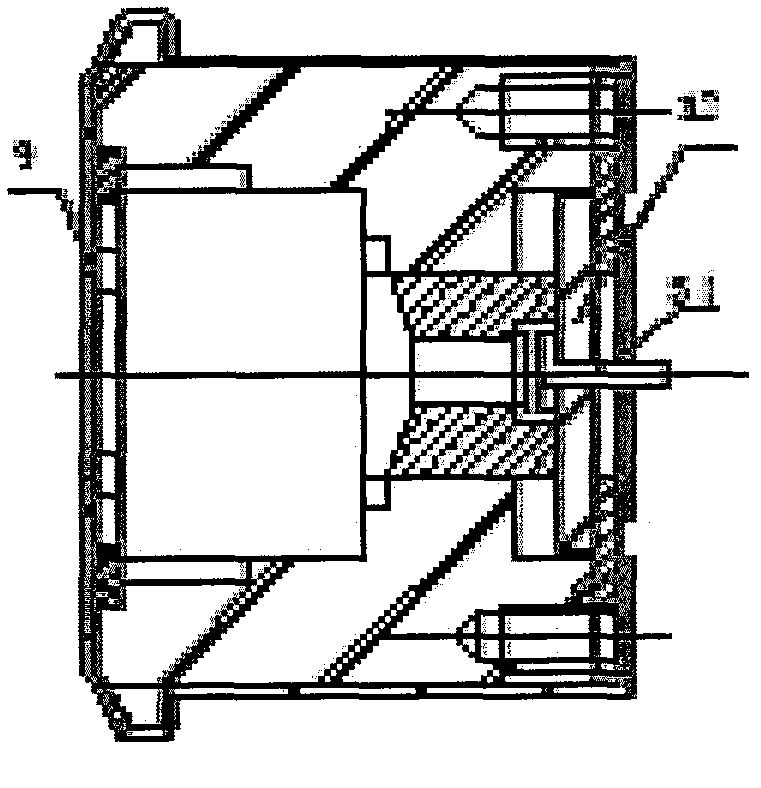

[0021] Example 2. If figure 2 As shown: the torque plate lock cylinder is composed of floating pin lock cylinder assembly, torque plate, gasket and other parts. The interconnection relationship is: the T-shaped end of the torque plate is connected to the lock cylinder, and the reverse side of the T-shaped is connected to the gasket ;The rear end of the lock body is provided with a movable cavity corresponding to the T-shape of the torque plate and the gasket, a fixed cavity corresponding to the reinforcing pad and a connecting screw hole; the lock shell has a convex shoulder at the key insertion end , The shell mouth is provided with an inward-turned fastening edge.

[0022] This embodiment can reduce the input of the types of molds such as the lock body.

Embodiment 3

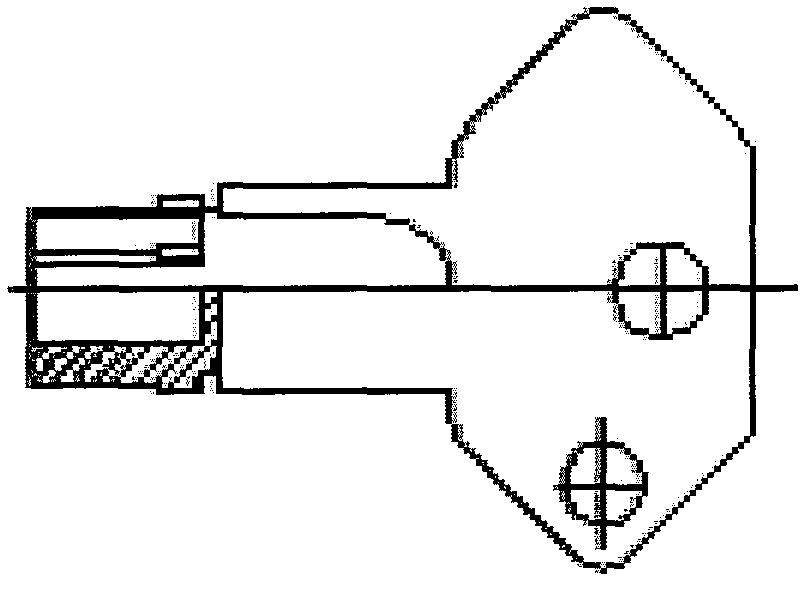

[0023] Example 3. As Figure 8 As shown: the lock cylinder is composed of a floating pin cylinder, an expansion pin, and a single-point bidirectional locking piece. The locking part is an arc-shaped special-shaped circlip, and the expansion pin is connected to the open end of the arc-shaped special-shaped circlip; it can also be set as a lock cylinder or directly connected to the arc-shaped special-shaped circlip by the lock cylinder connector; the lock head shell is open The through hole at the end corresponds to the diameter of the insertion section of the lockbolt head.

[0024] This scheme can realize the interlocking between the lock cylinder assembly and the lock bolt, and can adapt to the use requirements of special locks such as cable locks, chain locks, and various U-shaped locks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com