Inkjet printing quality fuzzy evaluation method

A fuzzy evaluation method and inkjet printing technology, which is applied in the direction of color measurement devices, image data processing, instruments, etc., can solve the problems of image quality evaluation results gap, inability to evaluate the printing quality of inkjet printing paper, etc., and achieve less test data , low cost, and simple supporting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

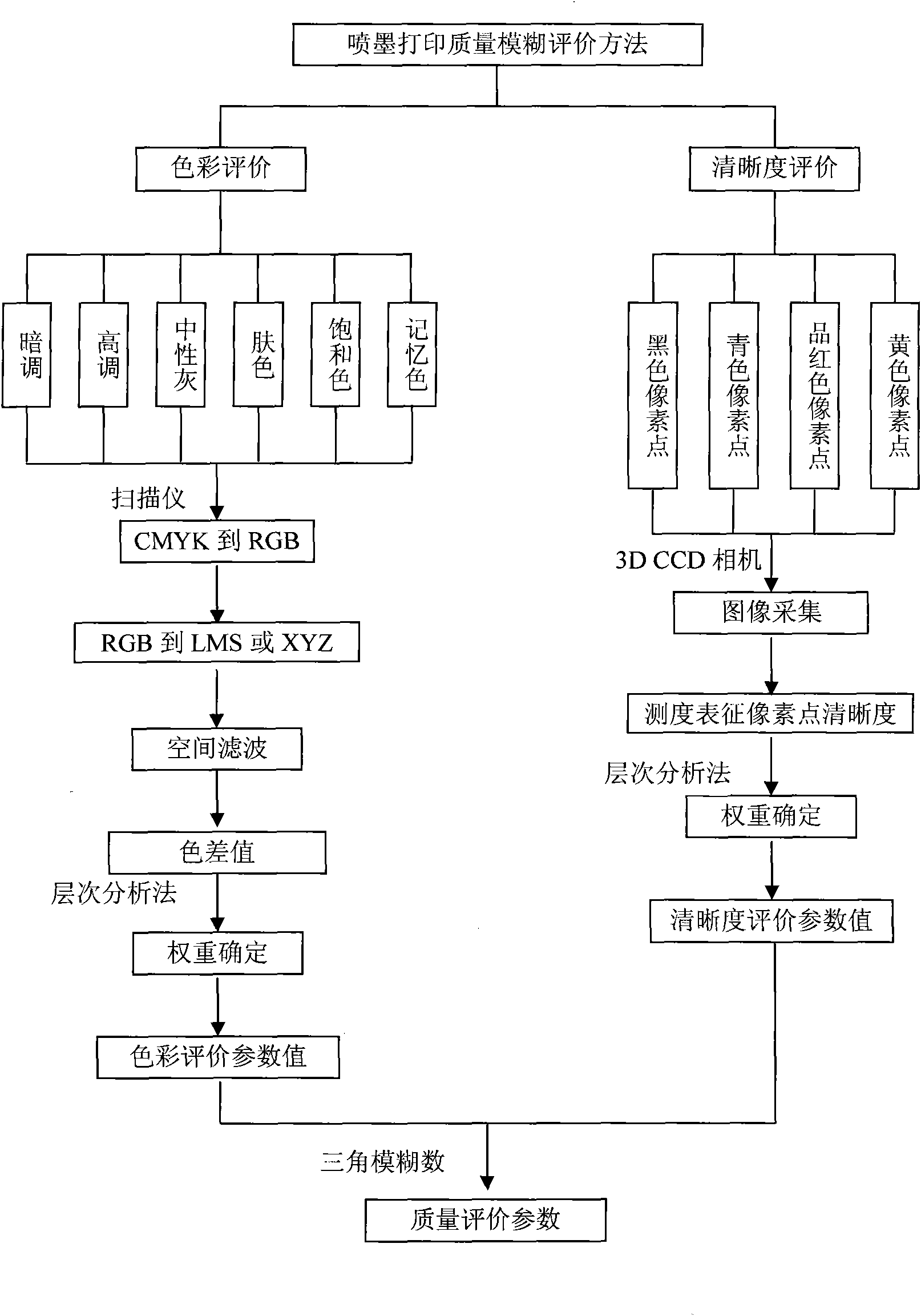

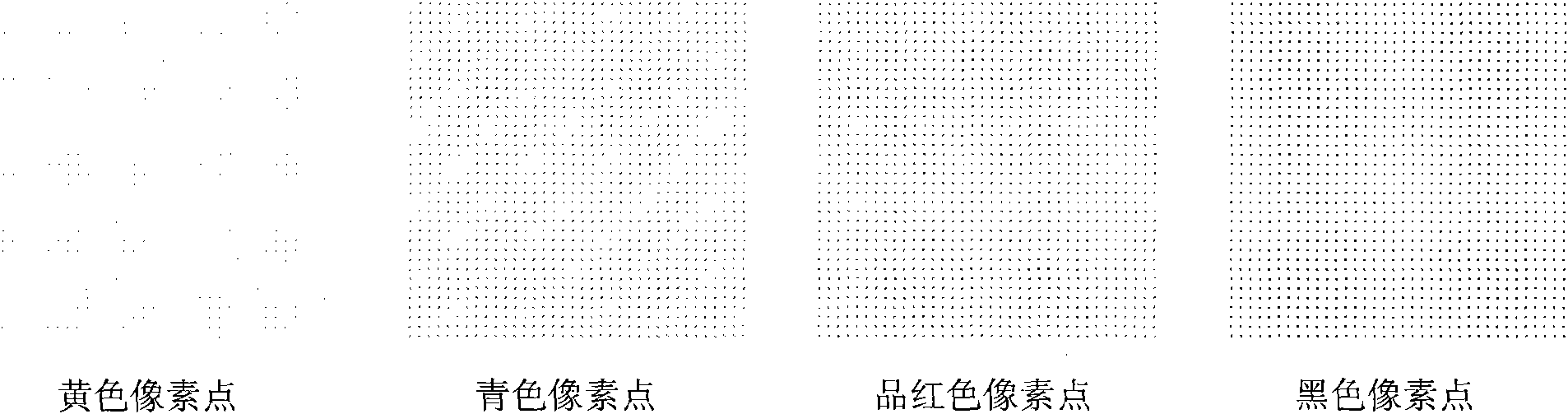

[0027] 1. Inkjet printing color reproduction evaluation method

[0028] like figure 1 As shown, the color scanner will print six quality factor images (dark key, high key, neutral gray, skin tone, saturated color and memory color) into digital images, and convert the scanned RGB image into XYZ mode. Since the spectral sensitive sensor of the scanner and the XYZ color matching function are converted nonlinearly, the RGB image obtained by the scanner cannot be directly and accurately converted into an XYZ image. In order to solve this problem, in this experiment, adopt LaserSoft ImagingTM SilverFast software to generate the characteristic document of the scanner, carry on the calibration to the scanner.

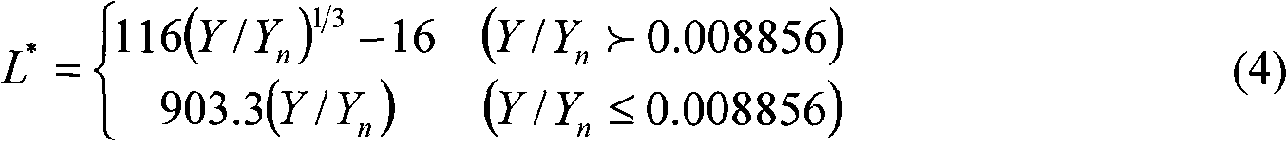

[0029] Transforms the scanned XYZ image and the original image into three opposite color channels, one luma channel and two chrominance channels. Images converted to three channels can be spatially filtered to mimic the spatial mixing effects of the human visual system. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com